Preparation method of high-bulkiness super-sensitive paper

A base paper and coating technology, applied in the field of preparation of high-bulk ultra-sensitive paper, can solve the problems of large loss of paper bulk and small loss of paper bulk, and achieve the effects of low production energy consumption, simple equipment, and strong fiber feeling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

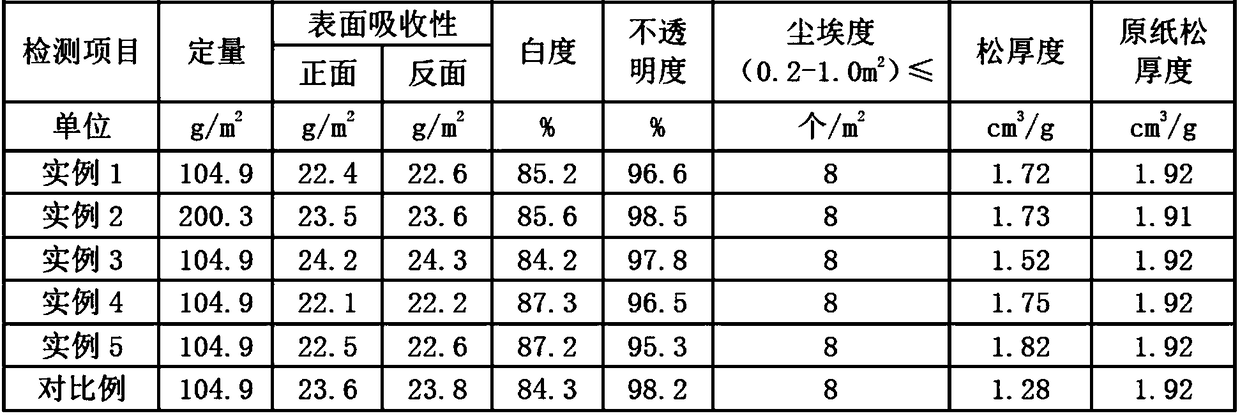

Examples

example 1

[0038] Step 1: base paper production

[0039] Pulp ratio: chemical hardwood pulp: chemical softwood pulp = 80: 20;

[0040] Beating degree: chemical hardwood pulp is 45°SR, chemical softwood pulp is 36°SR;

[0041] After the slurry preparation is completed, the slurry is treated with one-stage and three-stage slag removal, and 50Kg / ton of paper is added with light calcium carbonate, and 10Kg / ton of paper cationic starch and 20Kg / ton of paper AKD are metered before the pulping pump. , 0.5Kg / ton of c-PAM paper, through the rotor screen - headbox online, the pulp net speed ratio is controlled at 1.01, and finally dried into paper.

[0042] The main index of paper: quantitative is 81g / cm 2 , the bulk thickness is 1.92cm 3 / g, the nap strength is 2.5m / s, and the surface absorption is 23g / cm 2 .

[0043] Step 2: Coating treatment

[0044] Coating formula: (according to the dry weight percentage of coating)

[0045] Calcium carbonate: porcelain clay: polystyrene pigment: carbo...

example 2

[0055] Step 1: base paper production

[0056] Pulp ratio: chemical hardwood pulp: chemical softwood pulp: poplar APMP=50:30:20;

[0057] Beating degree: chemical hardwood pulp is 45°SR, chemical softwood pulp is 36°SR, poplar APMP is 55°SR;

[0058] After the slurry preparation is completed, the slurry is treated with one-stage and three-stage slag removal, and 80Kg / ton of paper is added with light calcium carbonate, and 10Kg / ton of paper cationic starch and 25Kg / ton of paper AKD are metered before the pulping pump. , 0.5Kg / ton of c-PAM paper, through the rotor screen - headbox online, the pulp net speed ratio is controlled at 1.01, and finally dried into paper.

[0059] The main index of paper: quantitative is 175g / cm 2 , the bulk thickness is 1.91cm 3 / g, the nap strength is 3.7m / s, and the surface absorption is 24g / cm 2 .

[0060] Step 2: Coating treatment

[0061] Coating formula: (according to the dry weight percentage of coating)

[0062] Calcium carbonate: titani...

Embodiment 3

[0070] With embodiment 1 base paper as base material, carry out coating treatment;

[0071] Coating formula: (according to the dry weight percentage of coating)

[0072] Calcium carbonate: titanium dioxide: polystyrene pigment: carboxylated styrene-butadiene latex: coating starch: PVA=40 parts: 20 parts: 20 parts: 10 parts: 5 parts: 5 parts;

[0073] Coating preparation technology is with example 1;

[0074] Paint index:

[0075] The solid content is 42±0.2%; the viscosity is 60±2.5mPa.s; the coating temperature is 40±0.5℃.

[0076] Coating process is the same as example 1;

[0077] Coating process requirement is the same as example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| whiteness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com