Comprehensive test and control system for engine bench based on CAN bus

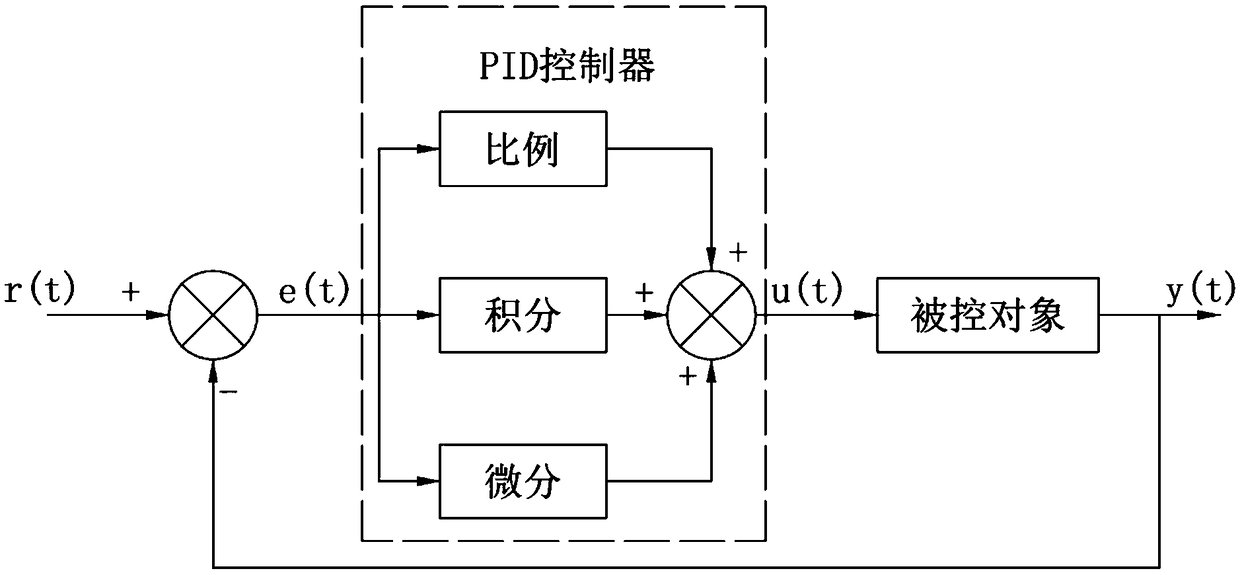

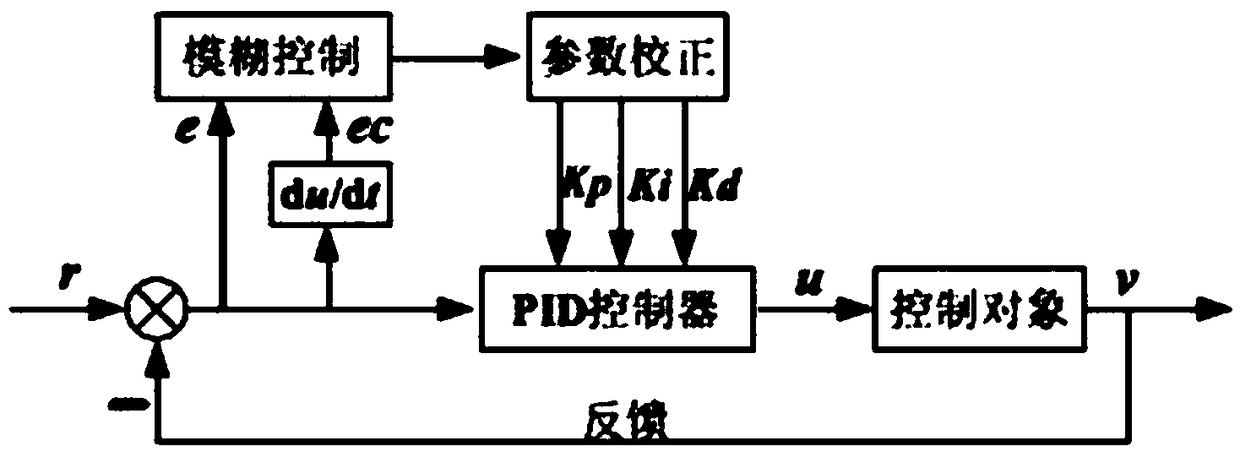

An engine bench and CAN bus technology, applied in the field of engine bench comprehensive test control system, can solve the problems of uneven development level and failure to meet performance test requirements, and achieve small steady-state error, simple control strategy, and control Precise and smooth results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to make the purpose, technical solution and advantages of the present invention clearer, the embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

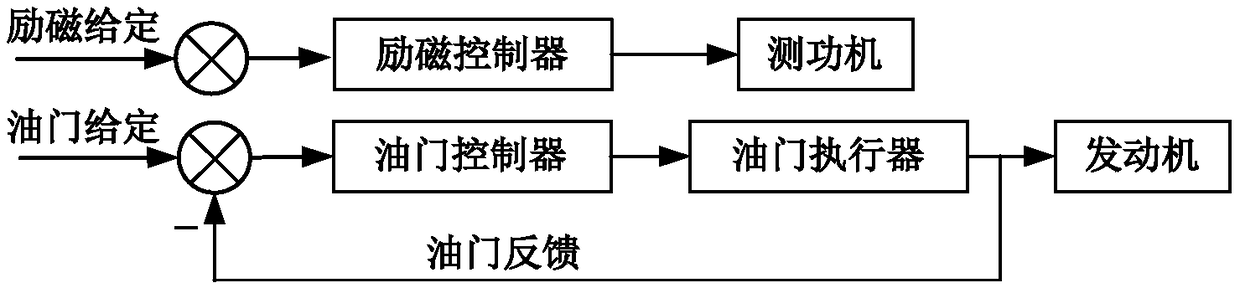

[0027] The embodiment of the present invention provides a CAN bus-based integrated test control system for an engine bench, including an engine test bench and an integrated measurement and control system.

[0028] The engine test bench includes a base, an engine mounted on the base, a dynamometer connected coaxially with the engine and used to apply a damping moment to the engine, and a throttle for controlling the power of the engine, and is also included in the The oil circuit and cooling water circuit connected to the above-mentioned engine, etc.

[0029] The integrated measurement and control system includes an upper computer and a lower computer with two-way communication through the CAN bus, the lower computer is the control core, and the lower com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com