Application method of numerical control macroprograms in parallel machine tool

An application method and macro program technology, which are applied in the application field of using numerical control macro programs in parallel machine tools, can solve the problems that interpolation programs cannot be used together, and achieve the effect of reducing costs and wide application prospects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

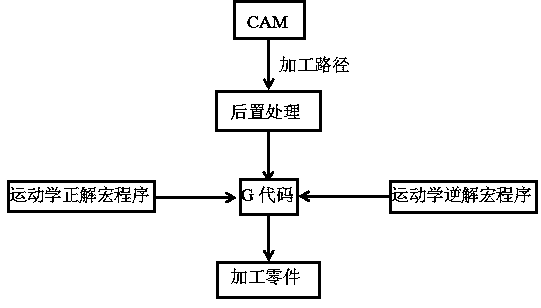

[0023] Please refer to figure 1 , the present invention provides a kind of application method utilizing numerical control macro program in parallel machine tool, comprises the following steps:

[0024] Step S1: input the data of the part to be processed including the three-dimensional model of the part, the type and size of the tool used, the cutting speed, etc. into the CAM software, and process it with the CAM software to obtain the machining path;

[0025] Step S2: convert the processing path into G code according to the post-processing program;

[0026] Step S3: construct the macro program of parallel machine tool kinematics inverse solution;

[0027] Step S4: construct the macro program of the positive solution of parallel machine tool kinematics;

[0028] Step S5: the G code calls the macro program of the reverse kinematics solution of the para...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com