Double-fed induction fan system based on coordinated control and low-voltage crossing method thereof

A doubly-fed induction fan, coordinated control technology, applied in the direction of control system, control generator, generator control circuit, etc., can solve the problems that can not fully meet the requirements of low voltage ride through, increase of DC voltage fluctuation, rotor surge current, etc. Achieve the effects of improving low-voltage ride-through capability, reducing torque oscillation, and reducing impedance value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described in detail below in conjunction with test examples and specific embodiments. However, it should not be understood that the scope of the above subject matter of the present invention is limited to the following embodiments, and all technologies realized based on the content of the present invention belong to the scope of the present invention.

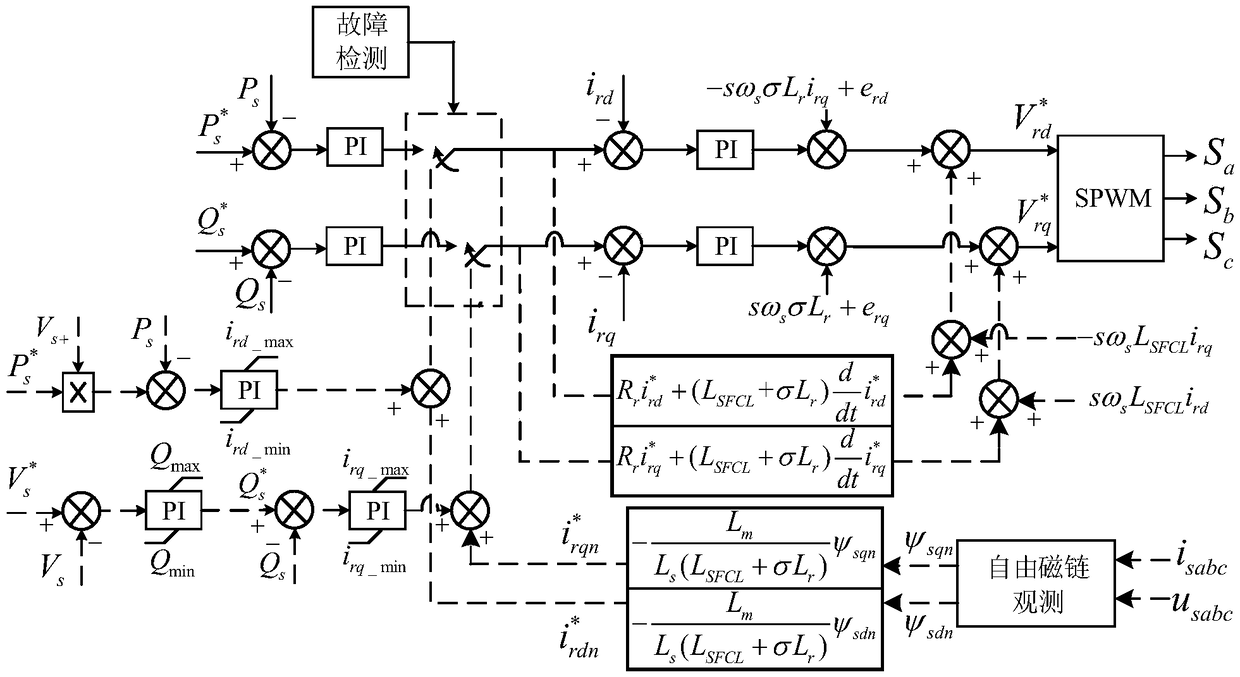

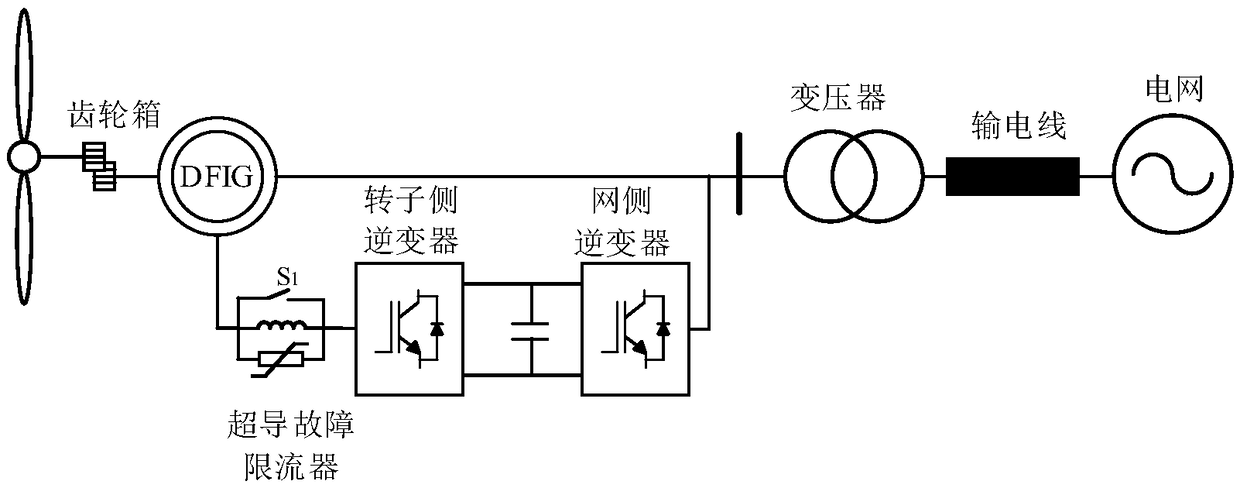

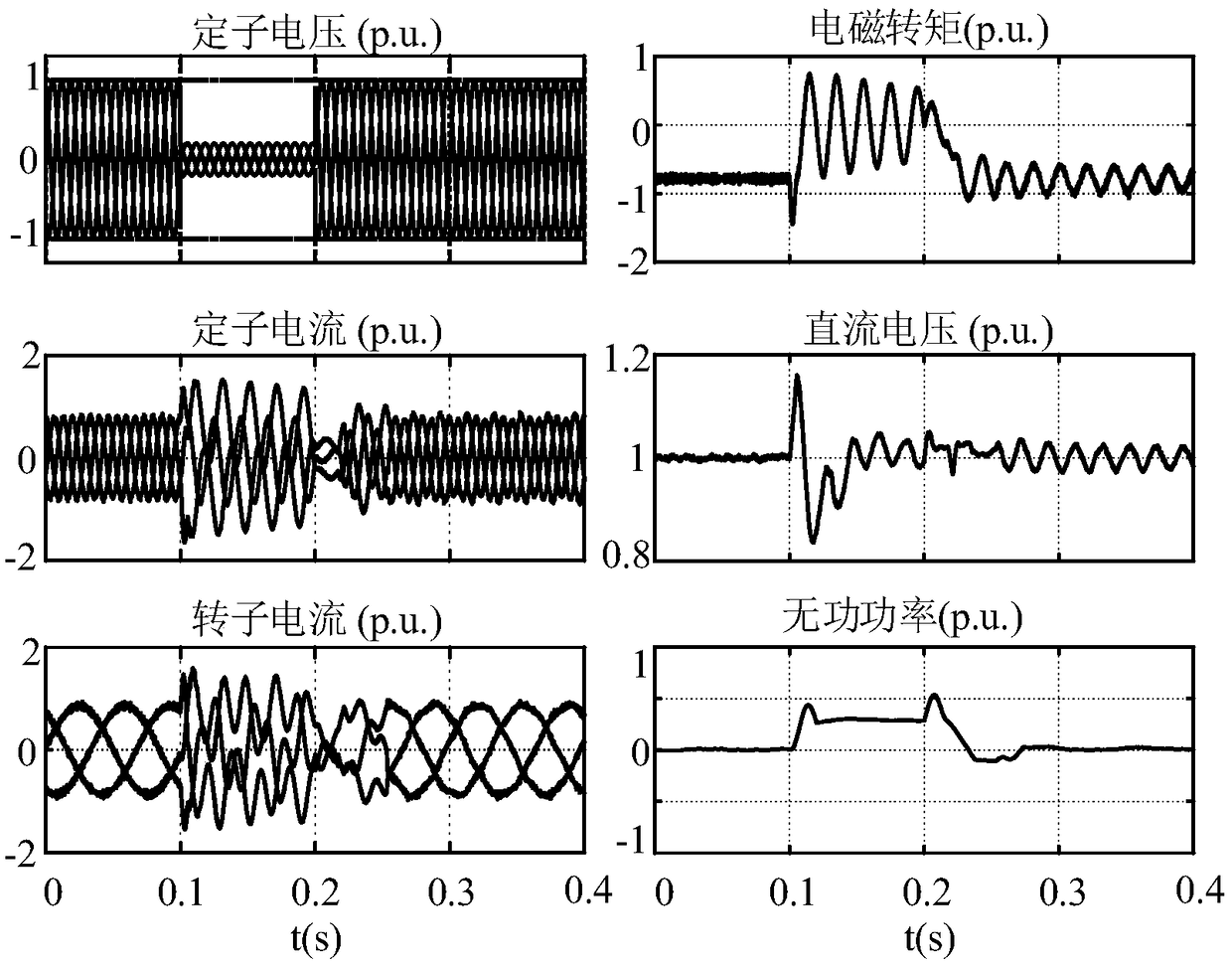

[0027] An embodiment of the present invention provides a coordinated control-based doubly-fed induction fan system (a doubly-fed induction fan system based on an inductive superconducting fault current limiter and current coordinated control). The doubly-fed induction fan system includes: a doubly-fed induction fan stator winding, a doubly-fed induction fan rotor, a rotor-side converter, and an inductive superconducting fault connected in series between the doubly-fed induction fan rotor and the rotor-side converter A current limiter; wherein, the inductive superconducting fault curr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com