High-strength steel plate and manufacturing method thereof

A technology of high-strength steel plates and manufacturing methods, applied in the direction of manufacturing tools, furnaces, heat treatment equipment, etc., can solve problems such as difficulty in meeting all these requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

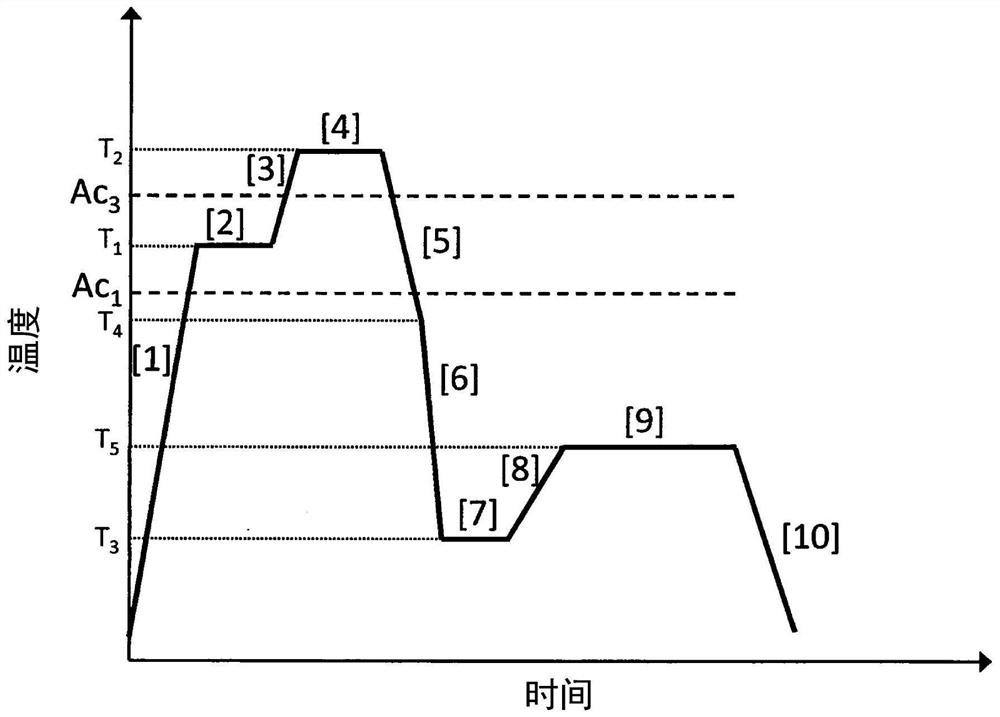

Method used

Image

Examples

Embodiment Construction

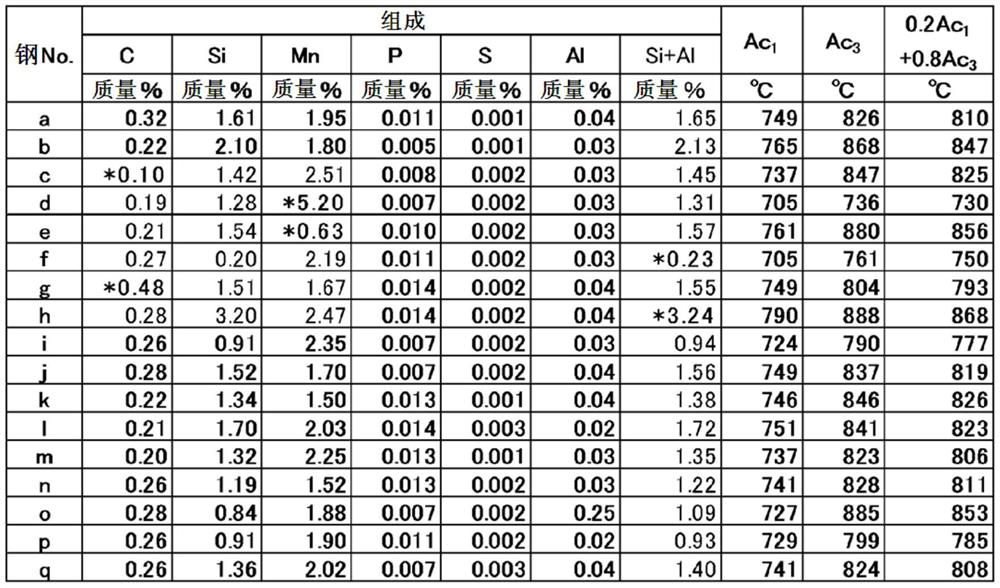

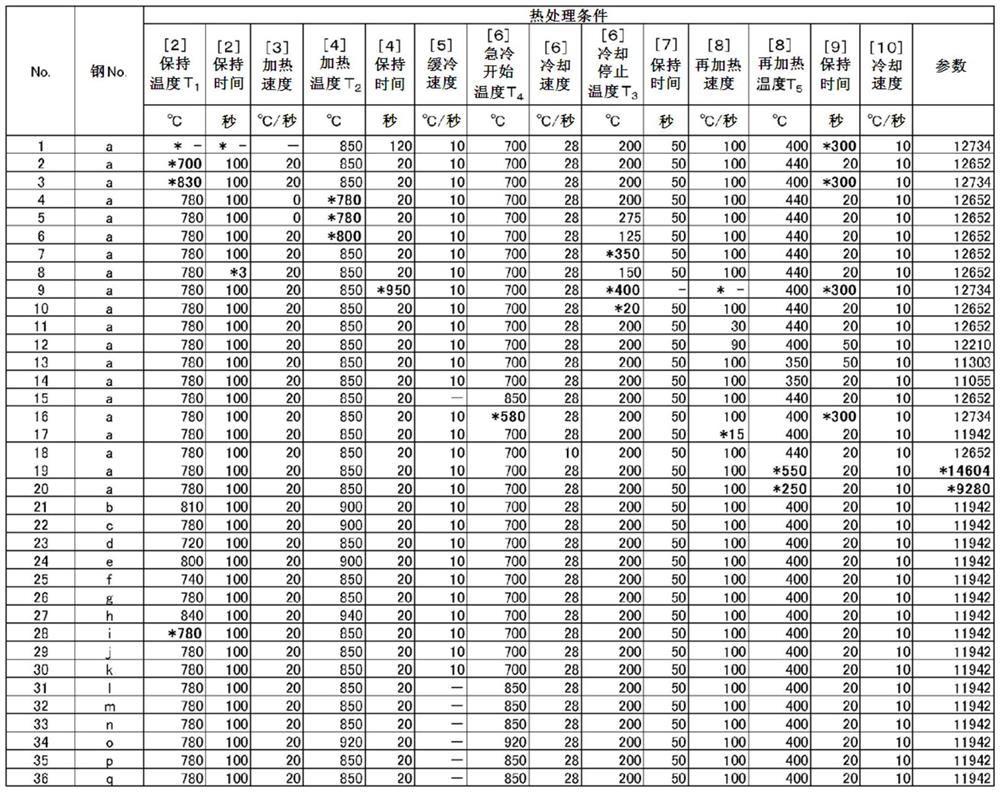

[0049] As a result of diligent research, the present inventors found that in steel having a predetermined composition, by making the steel structure (metal structure) achieve a ferrite fraction: 5% or less, tempered martensite and tempered bainite Total fraction of body: 60% or more, residual γ amount: 10% or more, average size of MA: 1.0 μm or less, corresponding to the half value of the Mn concentration distribution in the carbon-concentrated region of the retained austenite portion Width: 0.3% by mass or more, and the q value of small-angle X-ray scattering is 1nm -1 Scattering intensity: 1.0cm -1 Below, the product of tensile strength (TS), yield strength ratio (YR), (TS) and total elongation (EL) (TS×EL), hole expansion rate (λ), and fracture during tensile test can be obtained It is a high-strength steel sheet with a high level of thickness reduction ratio (RA) (impact resistance), ultimate bulging height, and spot-welded cross tensile strength (SW cross tensile).

[0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com