False twist yarn comprising dyeable polyolefin fibers

A polyolefin fiber and polyolefin technology, applied in the direction of single-component polyolefin rayon, conjugated synthetic polymer rayon, yarn, etc., can solve the problem of softness damage, light color development, and fiber hardening And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

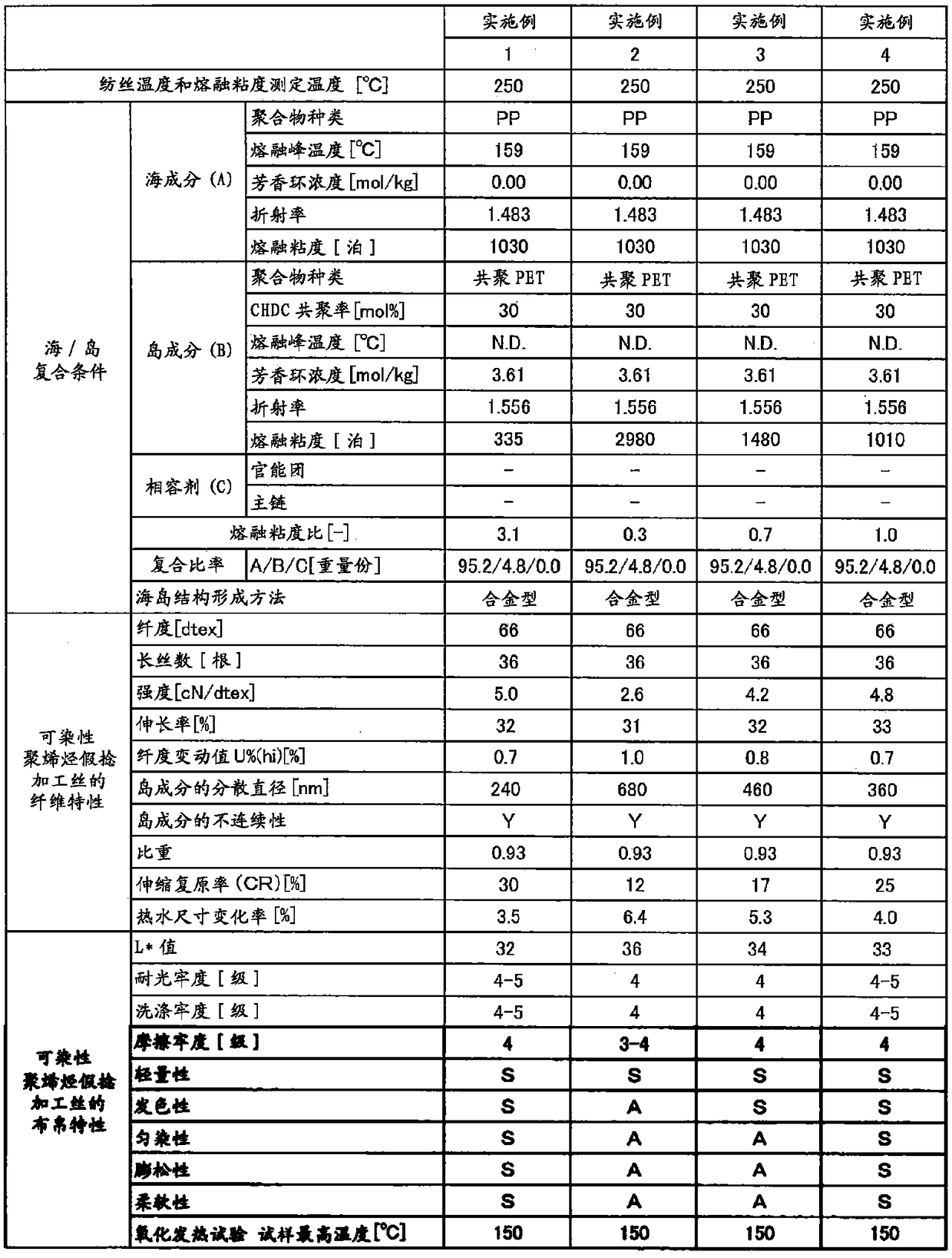

[0173] Add 95.2 parts by weight of polypropylene (PP) (1352F manufactured by Plastics, Taiwan, melting peak temperature 159°C, melt viscosity 1030 poise) and polyethylene terephthalate copolymerized with 30 mol% of 1,4-cyclohexanedicarboxylic acid 4.8 parts by weight of ester, as antioxidant, 1,3,5-tris[[4-(1,1-dimethylethyl)-3-hydroxy-2,6-dimethylbenzene as phenolic compound 0.05 parts by weight of methyl]-1,3,5-triazine-2,4,6(1H,3H,5H)-trione (Cyanox 1790 manufactured by CYTEC), tris(2, 0.05 parts by weight of 4-di-tert-butylphenyl) ester (Irgafos168 manufactured by BASF), bis(1-undecyloxy-2,2,6,6-tetramethylpiperidine- 0.6 parts by weight of 4-yl) carbonate (Adecastab LA-81 manufactured by ADEKA) was kneaded at a kneading temperature of 230° C. using a twin-screw extruder. After the strand discharged from the twin-screw extruder was cooled with water, it was cut into about 5 mm in length by a pelletizer to obtain pellets. After vacuum-drying the obtained pellets at 95° C....

Embodiment 2~7

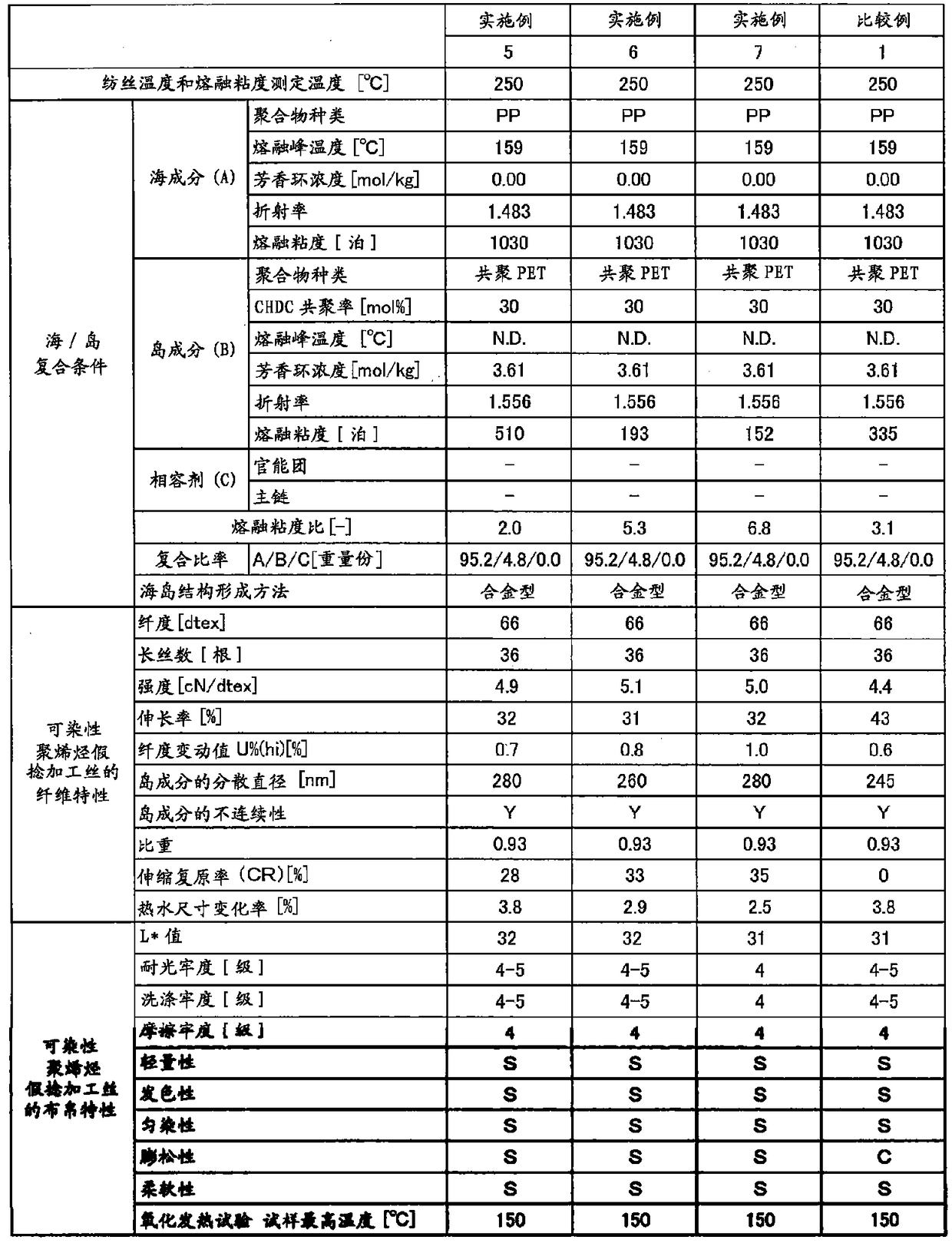

[0178] A false twisted yarn was produced in the same manner as in Example 1 except that polyesters (B) having different melt viscosities were used. Tables 1 and 2 show the fiber properties and evaluation results of the obtained false-twisted processed yarn.

Embodiment 8~14

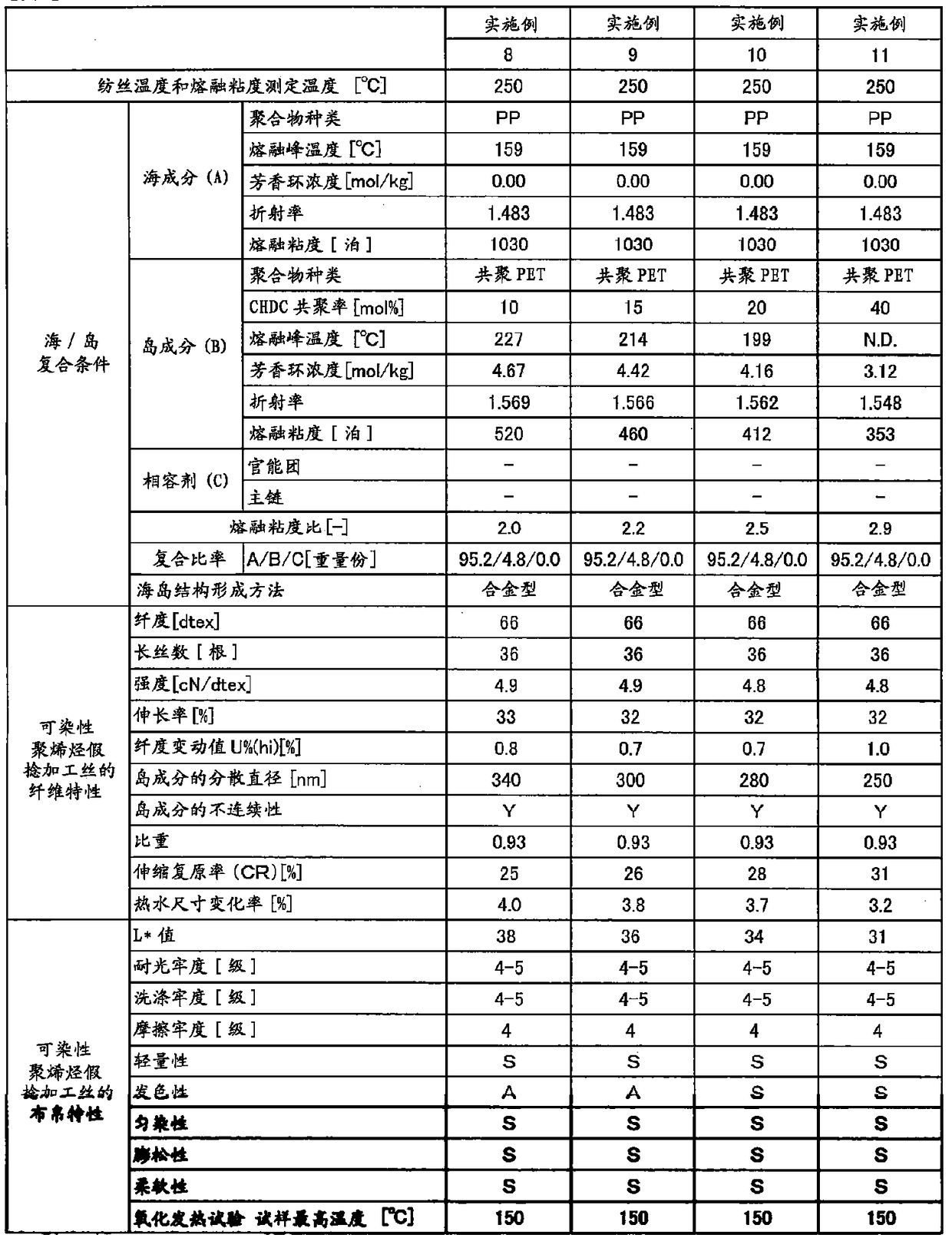

[0183] A false twisted yarn was produced in the same manner as in Example 1 except that the copolymerization ratio of cyclohexanedicarboxylic acid was changed as shown in Tables 3 and 4.

[0184] Tables 3 and 4 show the evaluation results of fiber properties and fabric properties of the obtained false-twisted textured yarns.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com