Micro LED array display device

A technology of LED arrays and display devices, applied in lighting devices, electrical components, circuits, etc., can solve the problems of increased size, complicated process and inconvenience, and achieve the effect of eliminating complexity and inconvenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

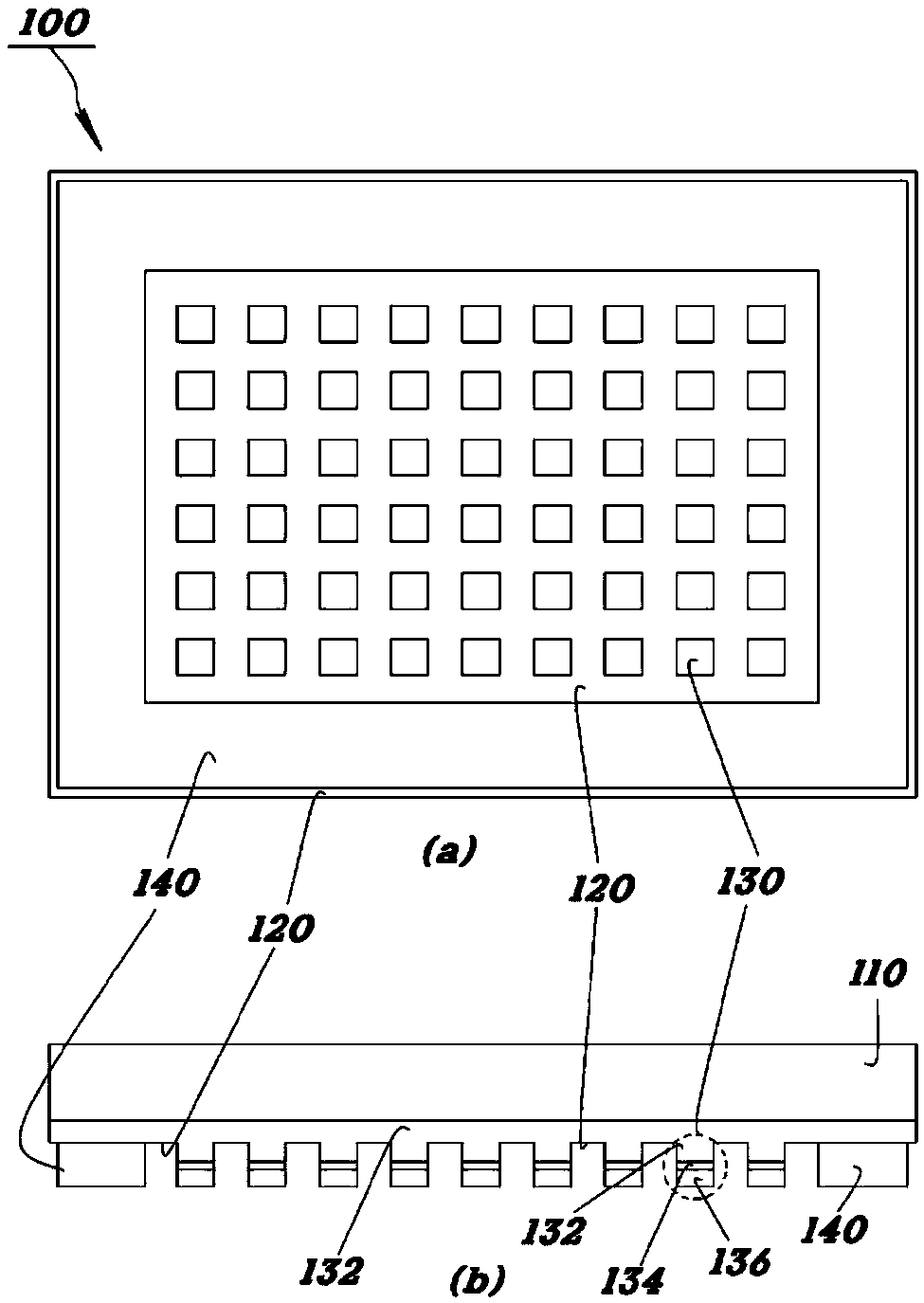

[0029] The present invention relates to a micro-LED array display device, which arrays micro-LED pixels through a mesa etching process (MESA etching) and flip-chip-welds the micro-LED pixels on a CMOS backplane, so that it can be applied to head-mounted displays ( Micro Display (Micro Display) such as Head Mounted Display (HMD) or Head Up Display (Head Up Display, HUD). In the present invention, micro-LED pixels are arranged through a mesa etching process when manufacturing LED chips, and are flip-chip welded on a CMOS backplane so that they can be driven individually. In addition, in the present invention, three elements of red, green and blue, that is, micro LED panels are arranged on the CMOS backplane, so that full color can also be realized.

[0030] Hereinafter, preferred embodiments of the present invention will be described with reference to the accompanying drawings. The drawings and the embodiments are simplified and shown so that those skilled in the art can easily...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com