A preparation method and application of tobacco refined high-temperature dry distillate

A high-temperature dry distillation and tobacco technology, which is applied in the field of electronic cigarettes, can solve the problems of high content of phenolic substances, difference in smoking feeling, and heavy smoke smell, and achieves the reduction of phenolic substance content, the moderate amount of aroma, and the improvement of internal smoking. quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

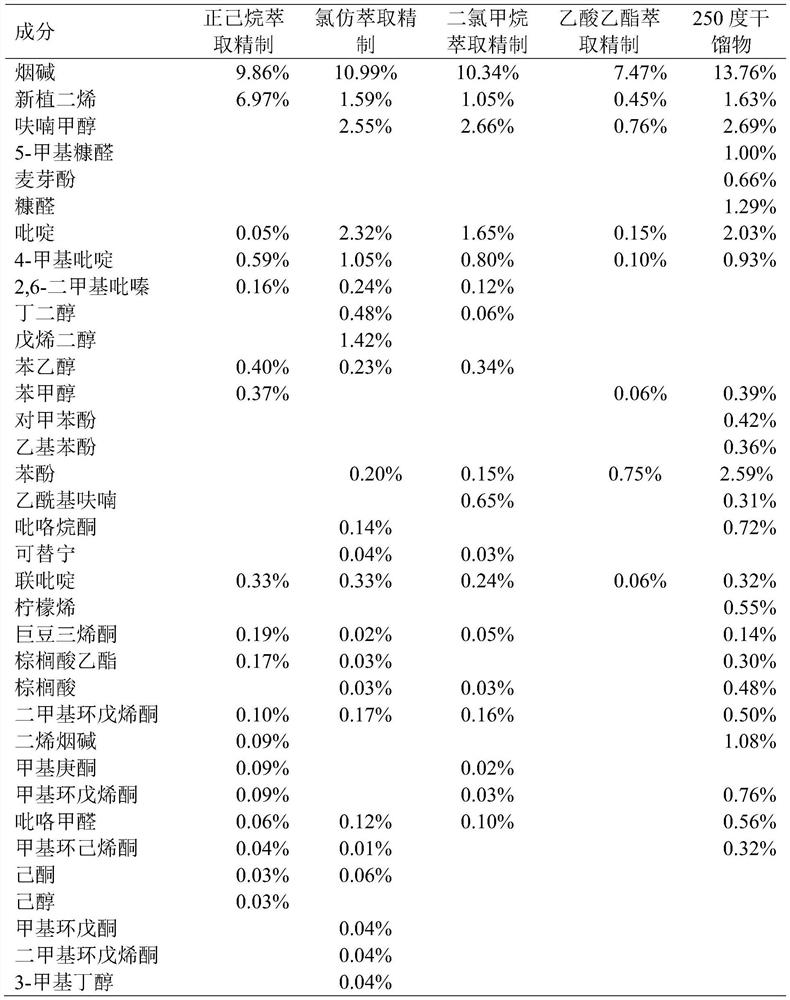

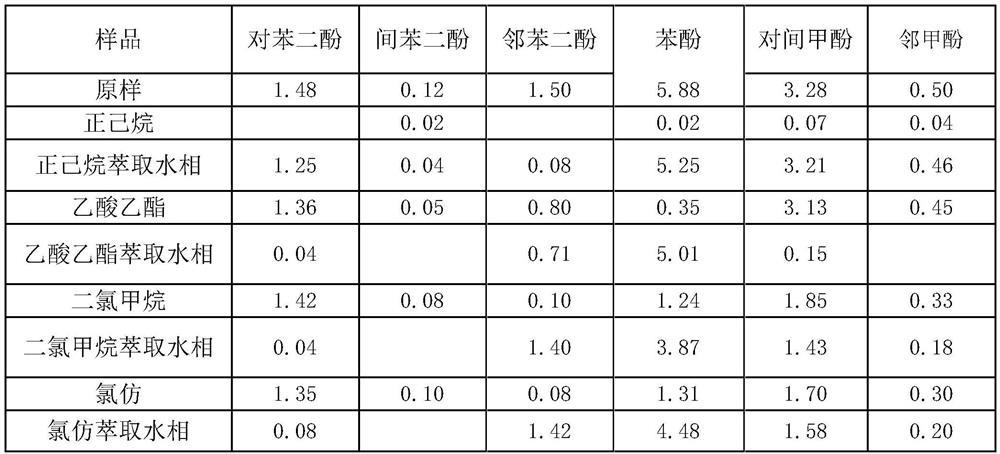

Embodiment 1

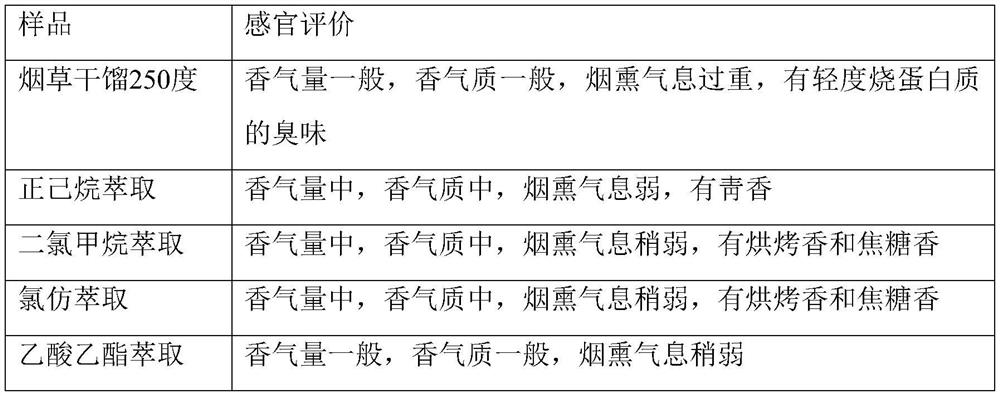

[0027] 100g of Xiangxi C2F was subjected to high-temperature dry distillation at 250 degrees, and the condensate and absorption liquid were combined to obtain 25g of high-temperature dry distillation. 25 g of water was added to the high-temperature dry distillate, extracted with 50 ml of n-hexane, the organic phase was concentrated and evaporated to dryness, and 25 g of atomizing agent was added to obtain a refined high-temperature dry distillate.

[0028] Take 1mL of the above-mentioned refined high-temperature dry distillate and add it to the electronic cigarette atomizer, and the professional vapers will test and smoke the electronic cigarette.

Embodiment 2

[0030] 100g of Xiangxi C2F was subjected to high-temperature dry distillation at 250 degrees, and the condensate and absorption liquid were combined to obtain 25g of high-temperature dry distillation. 25 g of water was added to the high-temperature dry distillate, extracted with 50 ml of dichloromethane, the organic phase was concentrated and evaporated to dryness, and 25 g of atomizing agent was added to obtain a refined high-temperature dry distillate.

[0031] Take 1mL of the above-mentioned refined high-temperature dry distillate and add it to the electronic cigarette atomizer, and the smoker will be smoked by a professional smoker.

Embodiment 3

[0033] 100g of Xiangxi C2F was subjected to high-temperature dry distillation at 250 degrees, and the condensate and absorption liquid were combined to obtain 25g of high-temperature dry distillation. 25 g of water was added to the high-temperature dry distillate, extracted with a mixture of 50 ml of chloroform and dichloromethane, the organic phase was concentrated and evaporated to dryness, and 25 g of atomizing agent was added to obtain a refined high-temperature dry distillate.

[0034] Take 1mL of the above-mentioned refined high-temperature dry distillate and add it to the electronic cigarette atomizer, and the smoker will be smoked by a professional smoker.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com