Method for preparing trimesic acid

A technology of trimesic acid and dimethyl benzoic acid is applied in the preparation of carboxylate, the preparation of organic compounds, chemical instruments and methods, etc., and can solve the problems of environmental pollution production process danger, low conversion rate and high cost , to achieve the effects of environmental protection and product purification, less tar content, and improved utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

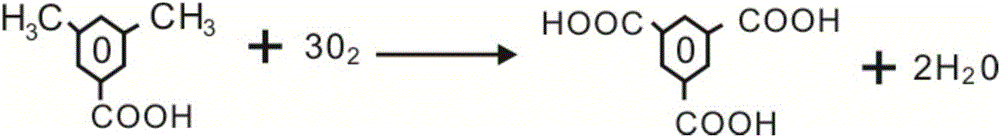

[0029] In the preparation method of trimesic acid provided by the invention, 3,5-dimethylbenzoic acid is oxidized to generate trimesic acid by a liquid phase oxidation method under the action of a catalytic system.

[0030] In the prior art, mesitylene is usually used to prepare trimesic acid. Compared with mesitylene, the 3,5-dimethylbenzoic acid provided by the present invention produces less tar in the process flow and has a higher yield , not only reduces pollution, but also facilitates product purification.

[0031] The liquid-phase oxidation method has the characteristics of fast reaction speed, short process and suitable for large-scale production.

[0032] Preferably, when carrying out the liquid-phase oxidation method, glacial acetic acid is used as a solvent.

[0033] Glacial acetic acid has a very high solubility to oxygen, which is beneficial to the rapid progress of the reaction.

[0034] Preferably, when performing the liquid-phase oxidation method, the oxidant...

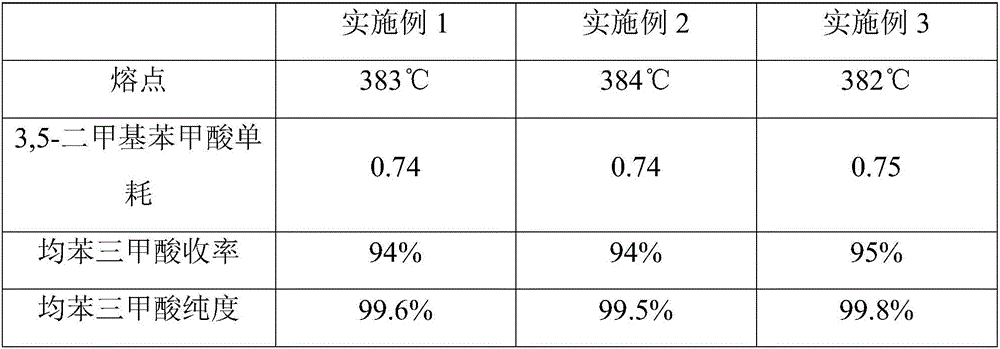

Embodiment 1

[0065] Put 100g 3,5-dimethylbenzoic acid, 680g glacial acetic acid, 8g cobalt acetate, 3g bromine Potassium chloride, 3g of zirconium acetate, and 1g of triethanolamine were heated up to 75°C, and oxygen was turned on at 1L / min until reflux, and the oxygen reaction was maintained under reflux for 6 hours. The raw material was less than 0.5% as the reaction end point, and the crude product and Mother liquor, the crude product is to be refined, and the mother liquor is absorbed by activated carbon and used mechanically.

[0066] Add 10g of activated carbon to the mother liquor in the upper batch, raise the temperature to 80°C to 90°C and keep it for adsorption for 1 hour, then cool to 60°C for filtration, weigh it and use it for the next batch. Add 100g of 3,5-dimethylbenzoic acid into a 1000ml reaction bottle; measure the water content of the mother liquor, if not enough, add acetic anhydride to make up to 680g of acetic acid, add 0.8g of cobalt acetate, 0.3g of potassium bromi...

Embodiment 2

[0069] Put 140g of 3,5-dimethylbenzoic acid, 760g of glacial acetic acid, 3g of cobalt acetate, and 5g of acetic acid into a 1000mL reaction flask equipped with a mechanical stirring device, an oxygen-passing glass tube, a constant-pressure dropping funnel, a thermometer, and a reflux condenser. Manganese, 5g sodium bromide, 5g cerium acetate, and 3g triethanolamine, heat up to 85°C, turn on oxygen 1L / min, until reflux, keep reflux and react with oxygen for 7 hours, take a sample to detect that the raw material is less than 0.5% as the reaction end point, cool The crude product and the mother liquor are obtained by filtration, the crude product is to be refined, and the mother liquor is absorbed by activated carbon and used mechanically.

[0070] Add 10g of activated carbon to the mother liquor in the upper batch, raise the temperature to 80°C to 90°C and keep it for adsorption for 1 hour, then cool to 60°C for filtration, weigh it and use it for the next batch. Add 140g of 3,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com