A kind of preparation method of austenitic stainless steel spring wire with high mechanical performance

A technology of austenitic stainless steel and spring wire is applied in the field of preparation of austenitic stainless steel spring wire with high mechanical properties, which can solve the problems of low elongation of stainless steel wire, poor straightness of finished spring, and fracture of stainless steel wire. , to achieve the effects of improved process stability, severe deformation, and increased elongation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] The preparation method of the high mechanical performance austenitic stainless steel spring wire of the present embodiment comprises the following steps:

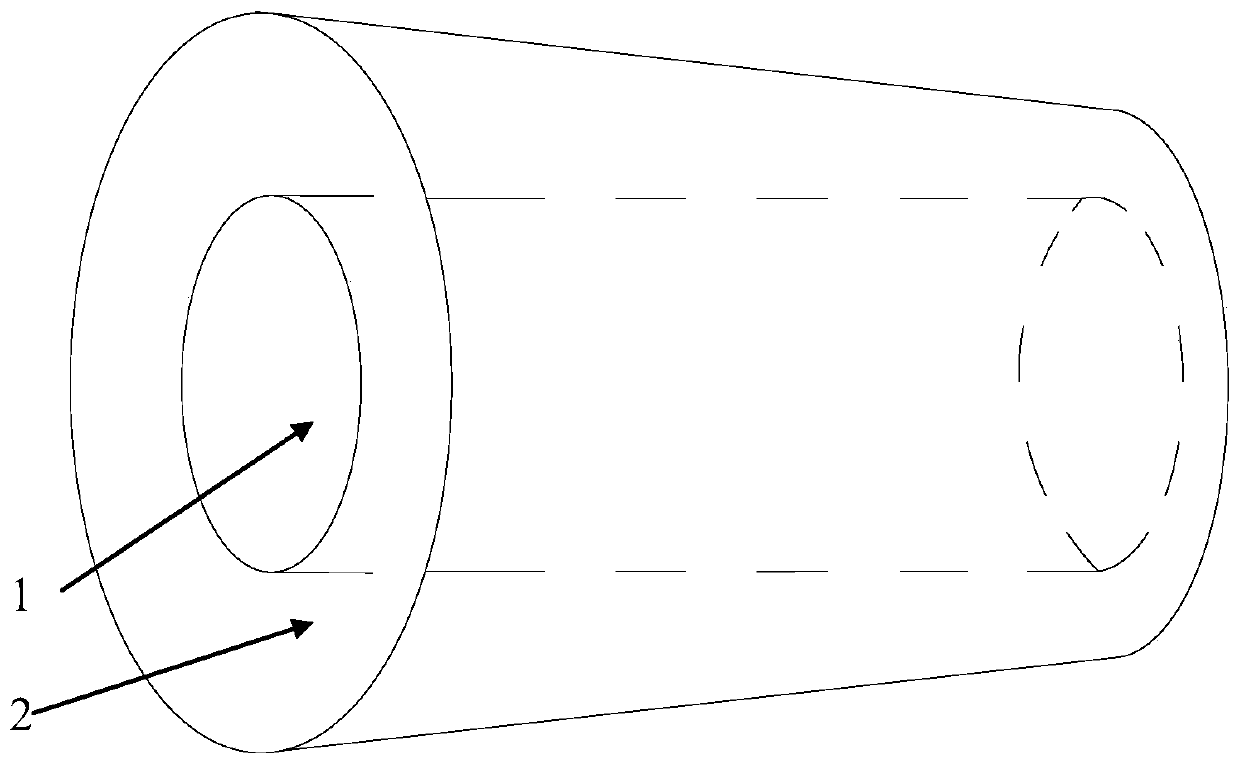

[0033] 1. Pretreatment of austenitic stainless steel bars

[0034] Such as figure 1 , take an austenitic stainless steel rod 1 with a diameter of 47mm, and seal it in a tapered copper tube 2. The tapered copper tube 2 is a tapered copper tube with equal inner diameter and variable wall thickness. 15°, the wall thickness of the small head end is 10mm, the two ends of the tapered copper tube 2 are sealed and welded with copper rods, and the tapered copper tube 2 sealed with the austenitic stainless steel rod 1 is heated to 300°C through an induction coil to obtain Pretreated austenitic stainless steel bars.

[0035] 2. Preparation of austenitic stainless steel spring wire with high mechanical properties

[0036] Step 1. Perform single-pass cold extrusion on the pretreated austenitic stainless steel bar to obtain a b...

Embodiment 2

[0042] The preparation method of the high mechanical performance austenitic stainless steel spring wire of the present embodiment comprises the following steps:

[0043] 1. Pretreatment of austenitic stainless steel bars

[0044] Such as figure 1 , take an austenitic stainless steel rod 1 with a diameter of 50 mm, and seal it in a tapered copper tube 2. The tapered copper tube 2 is a tapered copper tube with equal inner diameter and variable wall thickness. 18°, the wall thickness of the small head end is 10mm, the two ends of the tapered copper tube 2 are sealed and welded with copper rods, and the tapered copper tube 2 sealed with the austenitic stainless steel rod 1 is heated to 300°C through an induction coil to obtain Pretreated austenitic stainless steel bars.

[0045] 2. Preparation of austenitic stainless steel spring wire with high mechanical properties

[0046] Step 1. Perform single-pass cold extrusion on the pretreated austenitic stainless steel bar to obtain a ...

Embodiment 3

[0052] The preparation method of the high mechanical performance austenitic stainless steel spring wire of the present embodiment comprises the following steps:

[0053] 1. Pretreatment of austenitic stainless steel bars

[0054] Such as figure 1 , take an austenitic stainless steel rod 1 with a diameter of 30mm, and seal it in a tapered copper tube 2. The tapered copper tube 2 is a tapered copper tube with equal inner diameter and variable wall thickness. 30°, the wall thickness of the small head end is 23mm, the two ends of the tapered copper tube 2 are sealed and welded with copper rods, and the tapered copper tube 2 sealed with the austenitic stainless steel rod 1 is heated to 400°C through an induction coil to obtain Pretreated austenitic stainless steel bars.

[0055] 2. Preparation of austenitic stainless steel spring wire with high mechanical properties

[0056] Step 1. Perform single-pass cold extrusion on the pretreated austenitic stainless steel bar to obtain a b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com