Blast furnace gas and main air pipe communicating system

A blast furnace gas and main air pipe technology, applied in blast furnaces, blast furnace details, blast furnace parts, etc., can solve problems such as smooth production, energy saving and consumption reduction, avoid waste heat recovery and unstable heating in steelmaking, and ensure safety , Improve the effect of equipment utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

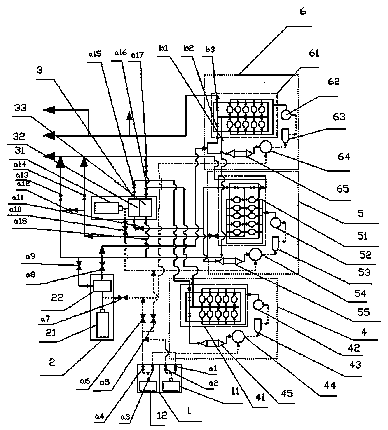

[0023] Such as figure 1 The shown blast furnace gas and main air duct network system includes a fan system, a blast furnace system and a control valve. The fan system is connected to the blast furnace system through a pipeline, and a control valve is arranged on the pipeline. The fan system and the blast furnace system are respectively set as 3, the fan systems are respectively the first fan system 1, the second fan system 2 and the third fan system 3, the blast furnace systems are respectively the first blast furnace system 4, the second blast furnace system 5 and the third blast furnace system 6, the first blast furnace system The first fan system 1, the second fan system 2 and the third fan system 3 are connected to each other;

[0024] In this embodiment, by connecting the three fan systems, when a problem occurs in one of them, another fan can work instead.

Embodiment 2

[0026] On the basis of the above-mentioned embodiments, in this embodiment, in order to prevent the two fans from working continuously for a long time, causing the pipeline to depressurize, the first fan system 1 is provided with a first main fan 11 and a backup fan 12. The air outlet of the air outlet is communicated with the standby blower fan 12 by the air duct, and the extra partial pressure is provided by setting the standby blower blower.

Embodiment 3

[0028] On the basis of the above-mentioned embodiments, in this embodiment, in order to use the kinetic energy of the fan to provide the power for gas transportation, the second fan system 2 is provided with a second fan 21, and the rear end of the second fan 21 is connected to a second fan through an air duct. A turbine 22, the turbine 22 is provided with a gas pipeline connected to the blast furnace system. The turbine 22 is driven to work by the second fan 21 so as to transport the gas into the pipeline system.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com