Contrast test method for evaluating stress corrosion cracking sensitivities of aluminum alloy fasteners

A stress corrosion and comparative test technology, which is applied in the direction of weather resistance/light resistance/corrosion resistance, test sample preparation, sampling, etc., can solve the problems of low test efficiency and achieve good reliability, high test efficiency, and high-efficiency stress resistance The effect of corrosive ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

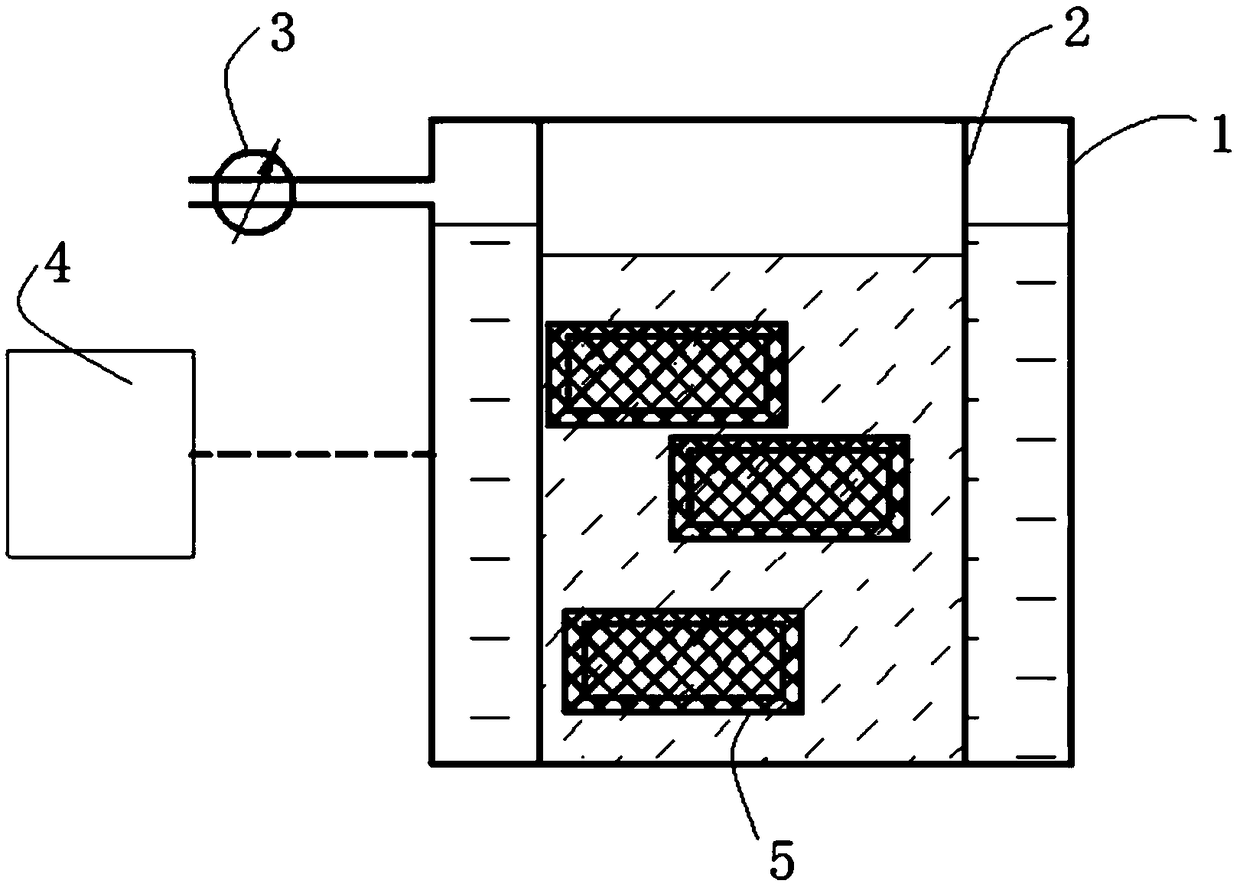

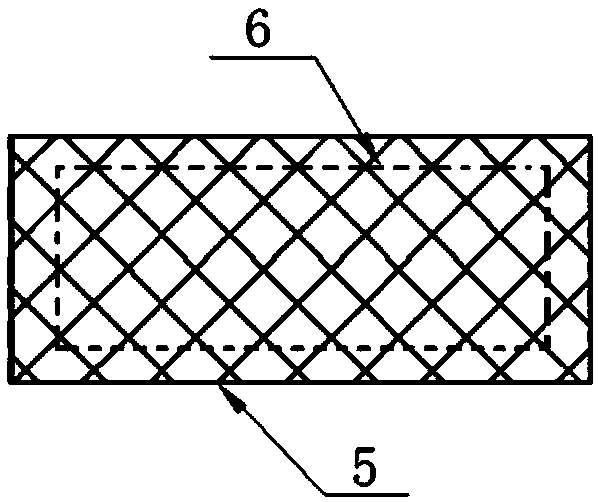

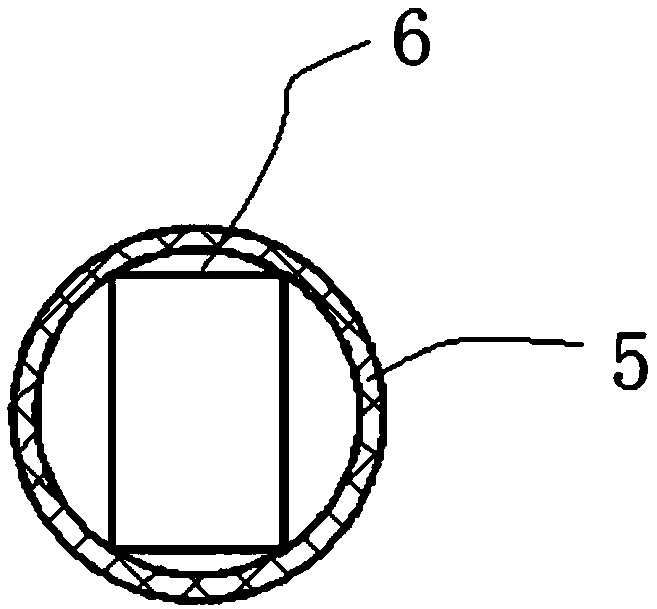

[0020] In the following examples, the stress corrosion test device is used to carry out relevant tests, and the structural schematic diagram of the stress corrosion test device is as follows Figure 1-Figure 3 As shown, the stress corrosion sample device includes a water bath box 1 and a corrosion medium container 2 arranged in the water bath box 1. The inner cavity of the corrosion medium container 2 is used to hold the corrosion medium used in the stress corrosion test, and the corrosion medium container 2 adopts thermal conductivity. Made of good materials, such as glass, steel materials, etc. A liquid level observation window is provided on the corrosive medium container 2 to facilitate the observation of the change of the liquid level in the corrosive medium container 2, so as to supplement water and other components according to the actual situatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com