Desulfurization device with online material replacement function

A desulfurization device and material technology, which is applied in the separation of dispersed particles, chemical instruments and methods, separation methods, etc., can solve the problems such as the inability to guarantee the compactness of the desulfurizer and the air tightness of the device, and achieve effective adjustment and improve practical effects. , to ensure the effect of compactness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

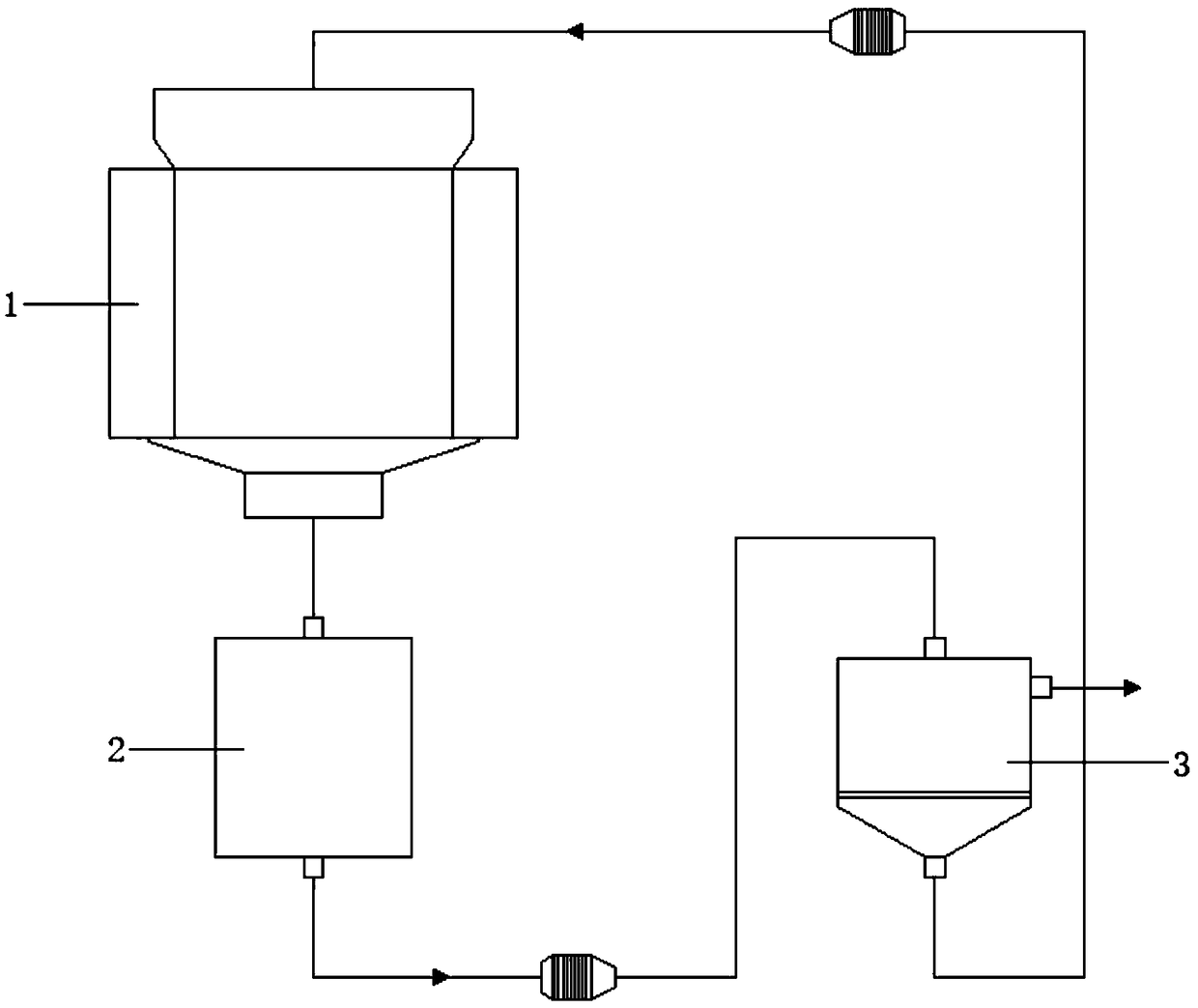

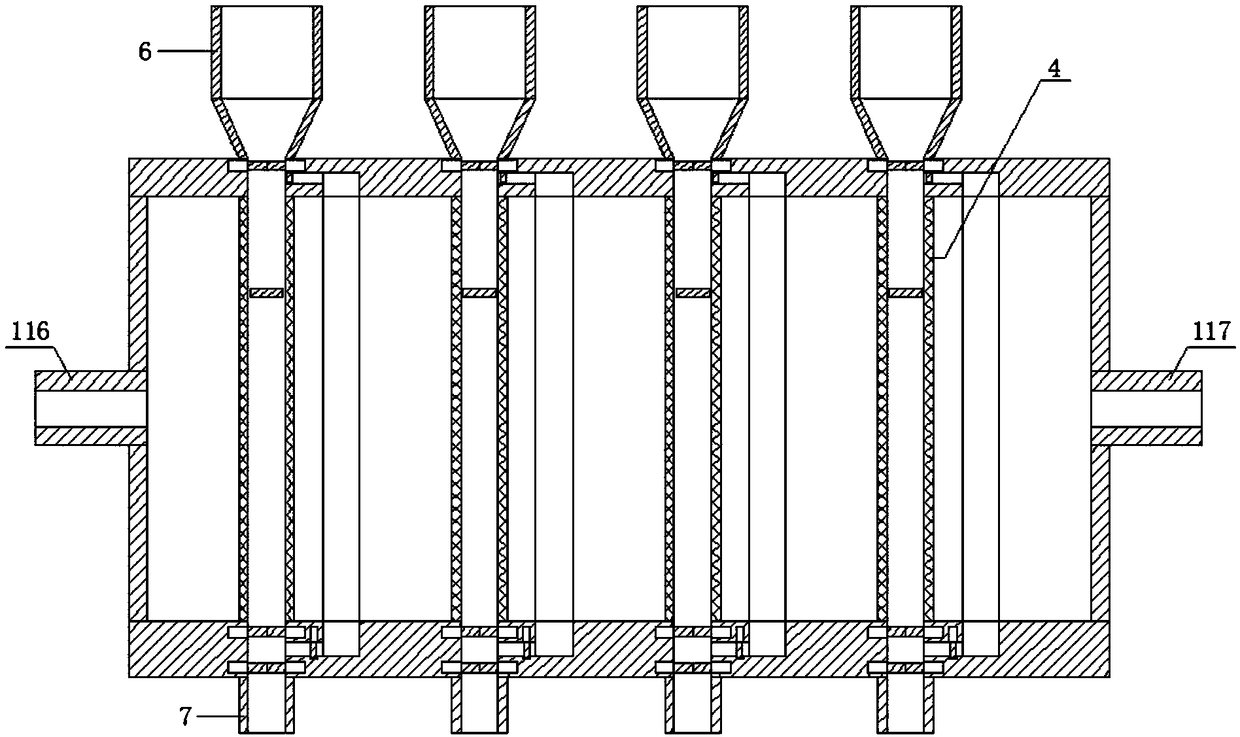

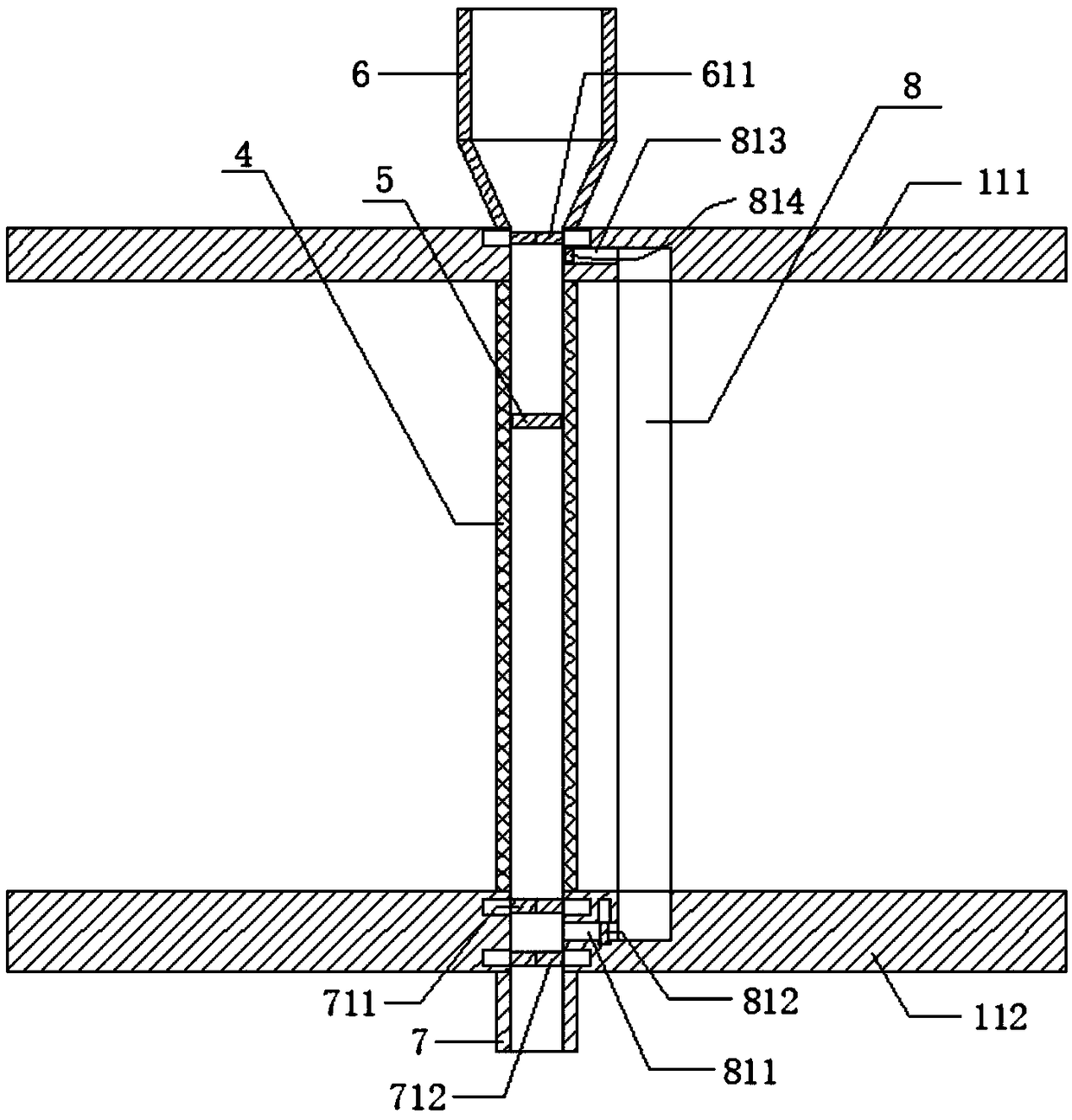

[0042] as attached Figure 1-6 As shown, the present invention includes an intake pipe 116 and an exhaust pipe 117 arranged on the desulfurization device 1, and at least two filter screens 4 arranged between the top plate 111 and the bottom plate 112 of the desulfurization device 1, and between the two filter screens 4 A desulfurizing agent is provided, the top plate 111 is provided with a feed port for filling the desulfurizing agent, the bottom plate 112 is provided with a discharge port for discharging the desulfurizing agent, and two sealed boxes are provided on both sides of the desulfurizing device 1 , the sealed box is divided into a sealed chamber and a motor chamber by a partition 114, a motor 10 is arranged in the motor chamber, a return-shaped slide rail 8 is arranged in the sealed chamber, and multiple An airtight block 9 that slides along the slide rail 8; a briquetting block 5 is also arranged between the two filter screens 4, and the two ends of the briquetting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com