Energy-saving anti-explosion mirror and energy-saving anti-explosion mirror production method

A production method and plastic film technology, applied in the field of display mirrors, can solve the problems of large material usage, high energy consumption, and high logistics costs, and achieve the effects of convenient operation, improved energy saving and environmental protection benefits, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

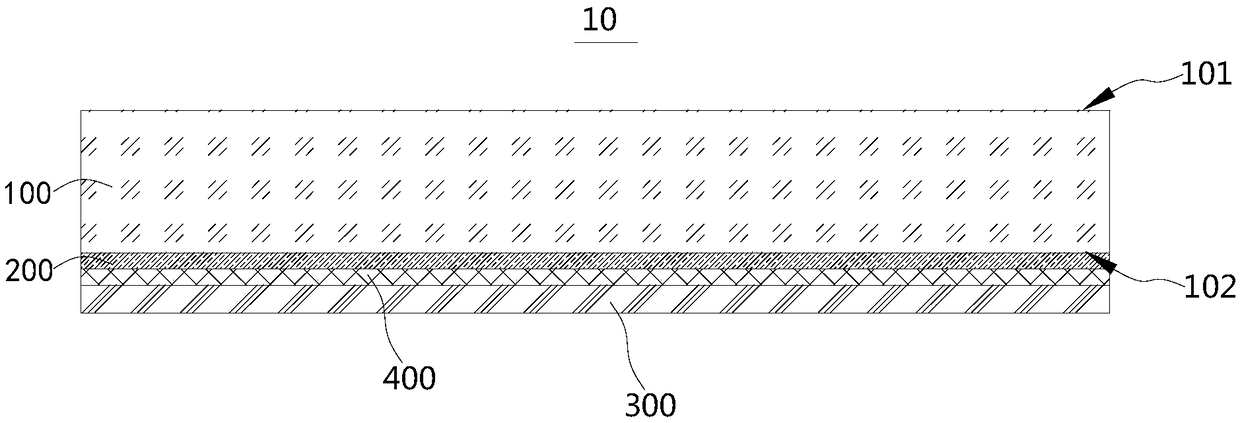

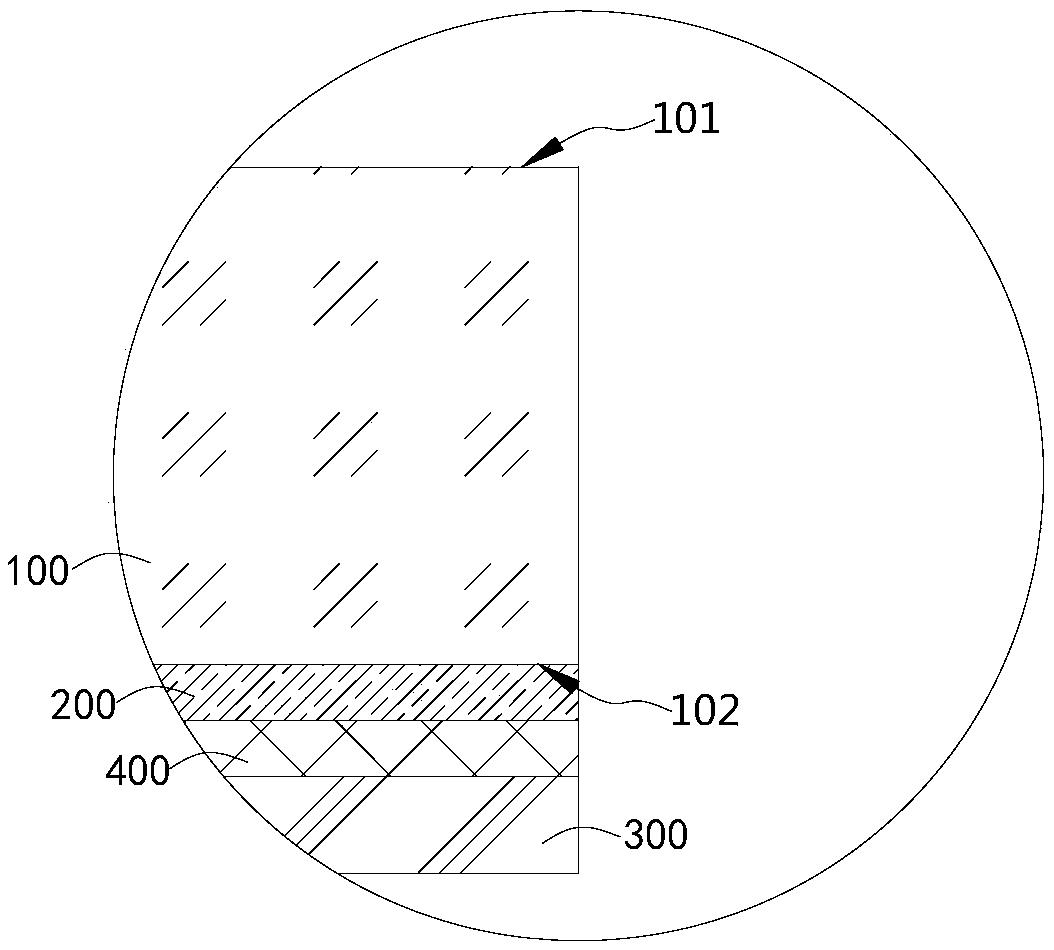

[0055] Please refer to figure 1 , figure 1 It is a schematic structural diagram of an energy-saving explosion-proof mirror 10 provided by an embodiment of the present invention. From figure 1 It can be seen that an energy-saving explosion-proof mirror 10 includes a glass plate 100 , a reflective layer 200 and a plastic film 300 .

[0056] A glass plate 100, the glass plate 100 includes opposite first surfaces 101 and second surfaces 102; and the thickness of the glass plate 100 is 2-3 mm;

[0057] A reflective layer 200, the reflective layer 200 is disposed on the second surface 102;

[0058]The plastic film 300 is disposed on the reflective layer 200 through the adhesive 400 .

[0059] Existing explosion-proof mirrors are coated with an aluminum layer on the 4-6mm glass, and then painted, so that the aluminum layer of the protective mirror is not easy to be scratched. The protective layer of the existing explosion-proof mirrors is paint, which is not environmentally frie...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com