Battery pack storage system and automatic battery swapping station of electric vehicle

A technology of electric vehicles and storage systems, which is applied in the direction of electric vehicles, charging stations, electric power devices, etc., can solve the problems of excessive space occupied by the battery exchange system, small number of battery packs stored, and no surrounding space margin, etc., to achieve saving Battery replacement time, saving manpower, and improving user experience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

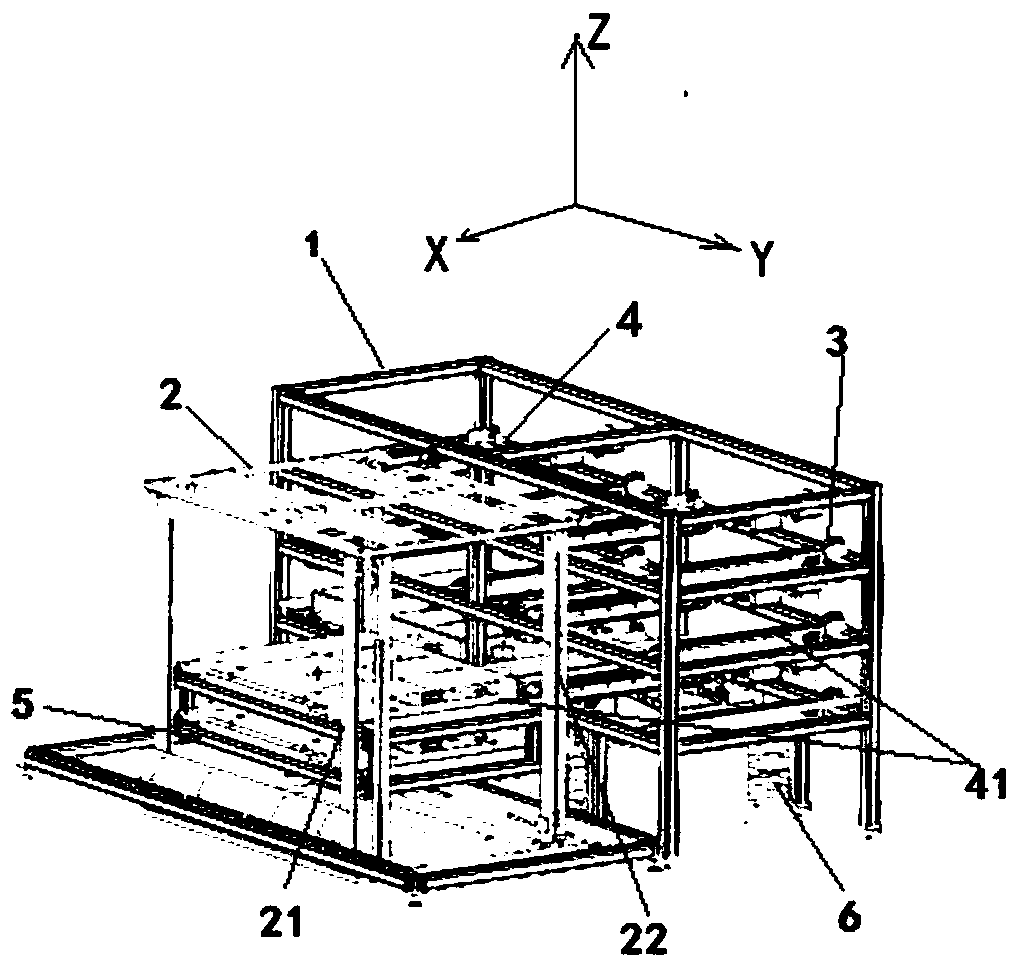

[0048] Such as image 3 As shown, the embodiment of the present invention provides a battery pack storage system for an electric vehicle automatic battery exchange station, including: a battery pack storage device 1 for storing battery packs and a battery pack storage device 1 and a power exchange trolley A battery pack exchange device 2 that transfers battery packs between them. Wherein, the battery pack storage device 1 has a battery pack storage area 3, and the battery pack storage area 3 has multiple layers of first battery pack storage units 4 arranged along the height direction Z; the battery pack exchange device 2 is located in the battery pack along the first direction X. One side of the storage device 1, the battery pack exchange device 2 has a second battery pack storage unit 5, and can move along the height direction Z, so as to enable the second battery pack storage unit 5 to store the first battery pack. Unit 4 realizes the height of battery pack exchange. It ca...

Embodiment 2

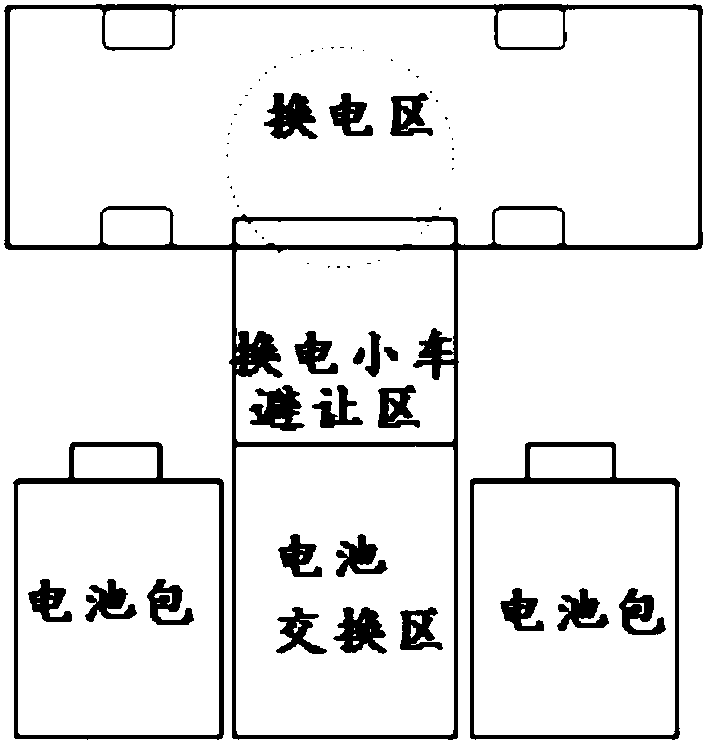

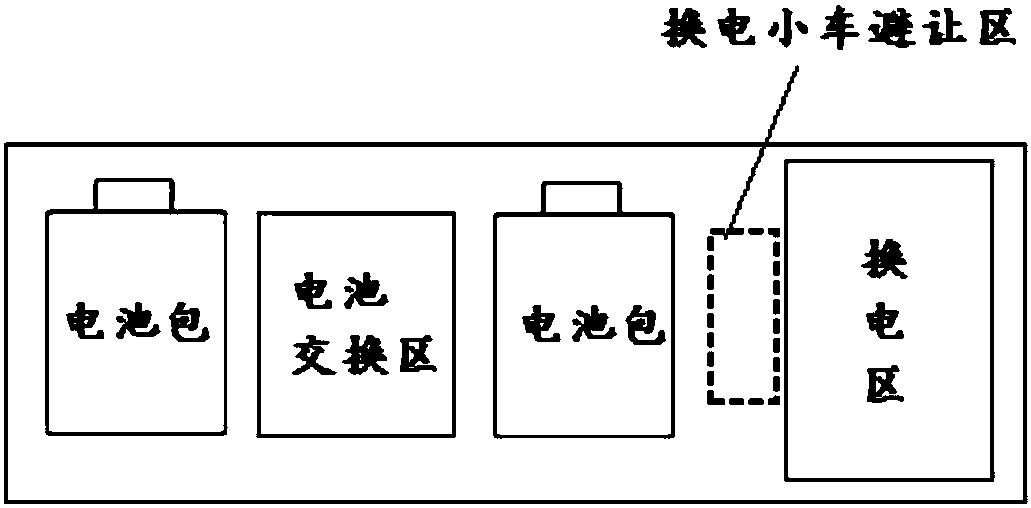

[0063] Such as Figure 4-Figure 7 As shown, the embodiment of the present invention provides an automatic battery swap station for electric vehicles, including the battery pack storage system described in Embodiment 1, and also includes: a battery swap trolley 7, a battery swap platform 8, and a guide rail 9. The battery exchange platform 8 is arranged on one side of the battery pack storage system along the first direction X, and is used to support and position the vehicle, and lift the vehicle to a preset battery exchange height. The guide rail 9 extends along the first direction X, one end of the guide rail 9 extends into the power exchange platform 8, and the other end extends to the battery pack exchange device 2; the battery exchange trolley 7 is arranged on the guide rail 9, and can move along the guide rail 9 to reciprocate to complete the transportation and exchange of the battery pack between the vehicle and the battery pack exchange device 2 .

[0064] Such as Fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com