Closed conveying pipe

A conveying pipe and closed technology, which is applied in the field of closed conveying pipes, can solve the problems of external environmental pollution, large assembly stress of conveying pipes and steel frames, cracking of welds, etc., and achieve the effect of improving conveying efficiency and avoiding wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further elaborated below in conjunction with the accompanying drawings and specific embodiments.

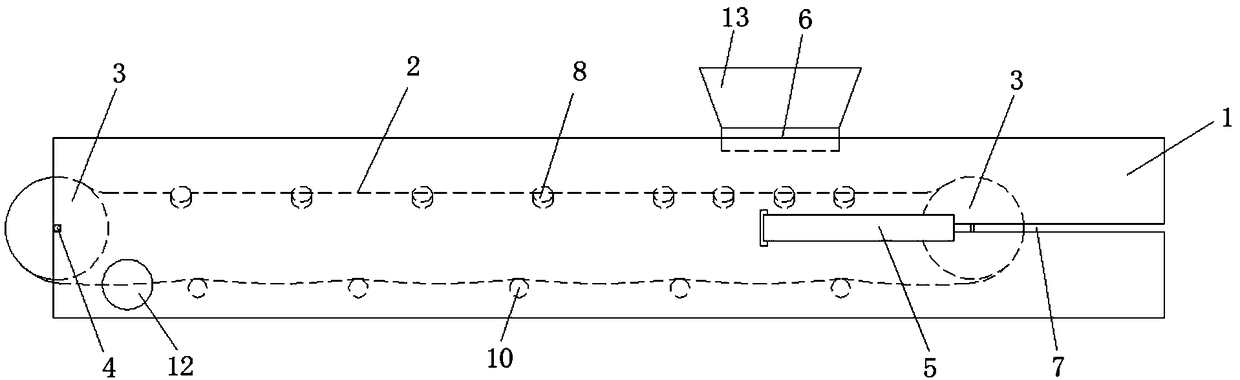

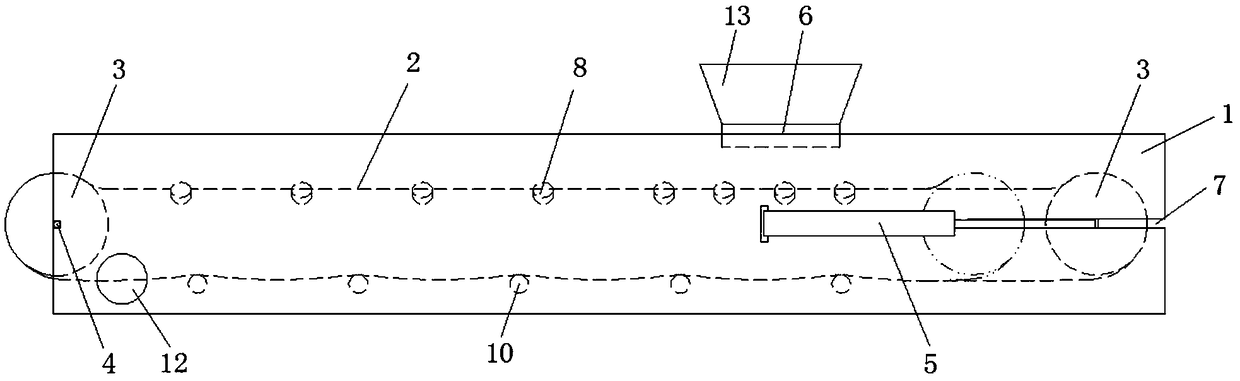

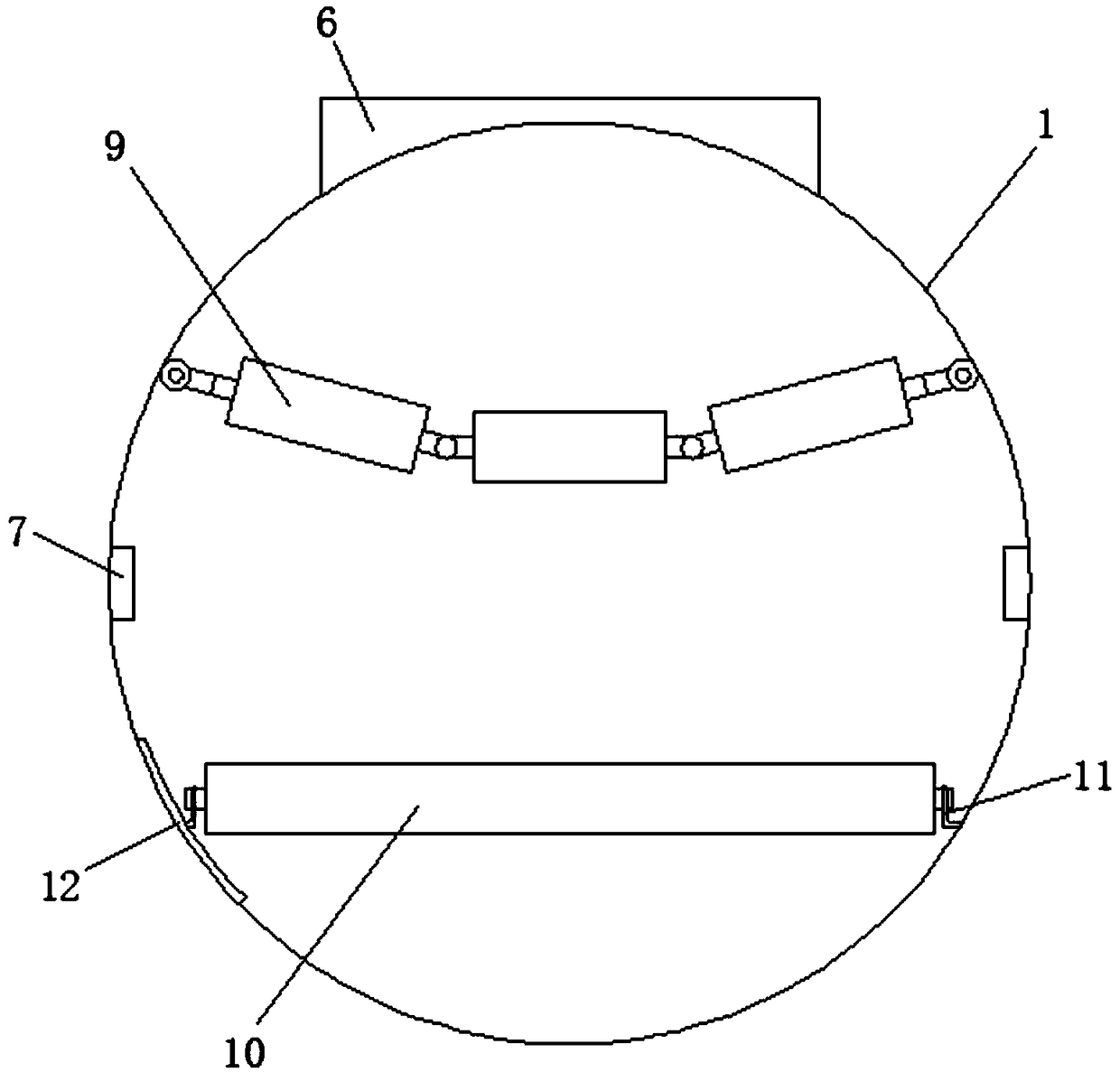

[0028] Such as Figure 1 ~ Figure 2 As shown, the closed conveying pipe includes a conveying device for conveying materials and a closed pipe 1 for dustproofing materials; the conveying device is located inside the closed pipe 1; the conveying device includes a conveying belt 2, a conveying roller wheel 3 and rotating shaft 4; one end of said rotating shaft 4 is connected to conveying roller 3, and the other end is connected to closed pipeline 1; one end of said closed pipeline 1 is provided with tension regulator 5; said tension regulator 5 is connected with The rotating shaft 4 near its one end is connected.

[0029] In the existing tension adjustment work, it is generally necessary to start the motor first to make the conveyor belt 2 work, and then manually adjust the screw rod or the screw to adjust the tension degree; in this process, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com