Sewage treatment system and sewage treatment method for wire producing factory

A sewage treatment system and factory technology, applied in the direction of water/sewage treatment, neutralized water/sewage treatment, water/sewage multi-stage treatment, etc., can solve the problem of poor removal of suspended solids, unsuitable for wire-making plants, and pertinence To reduce the complexity of the regeneration process, to achieve efficient and complete sewage treatment, and to prolong the flocculation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

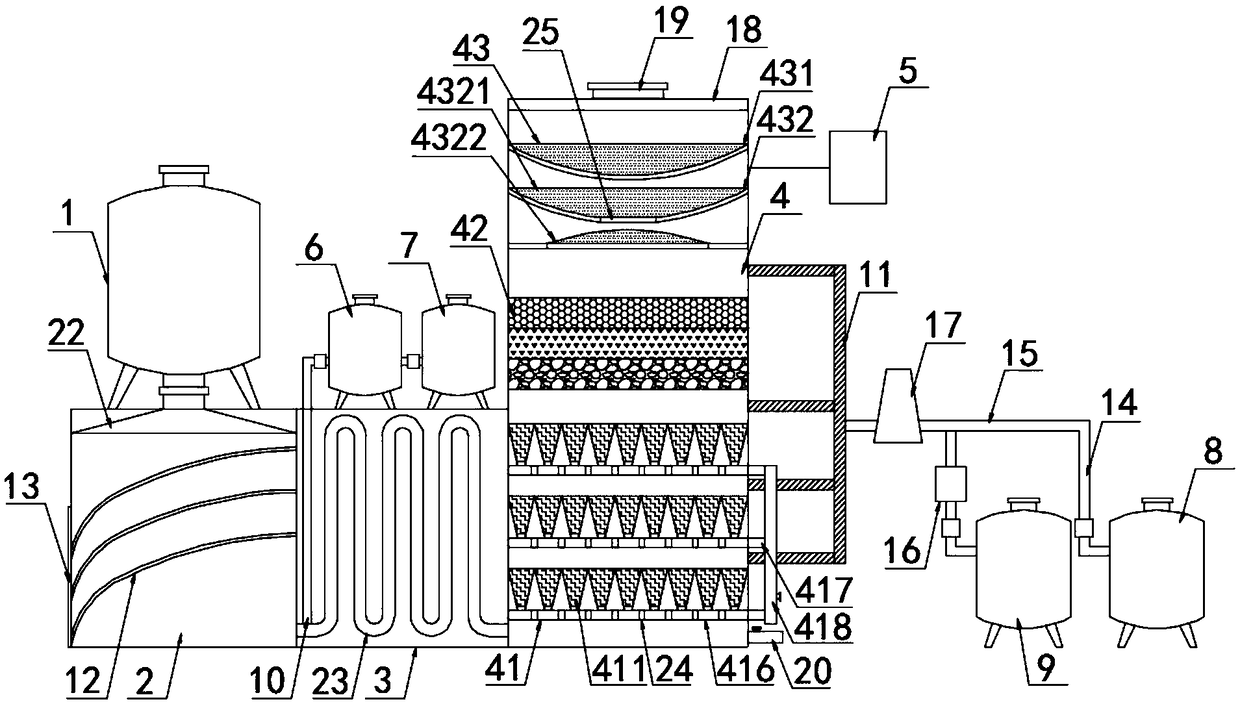

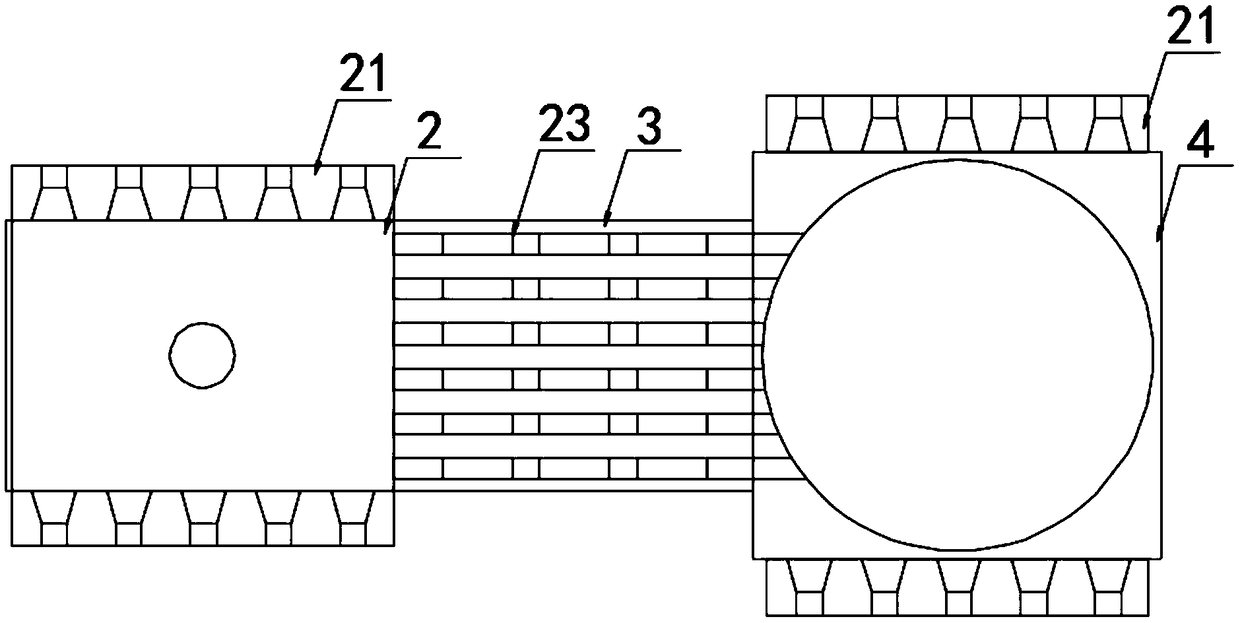

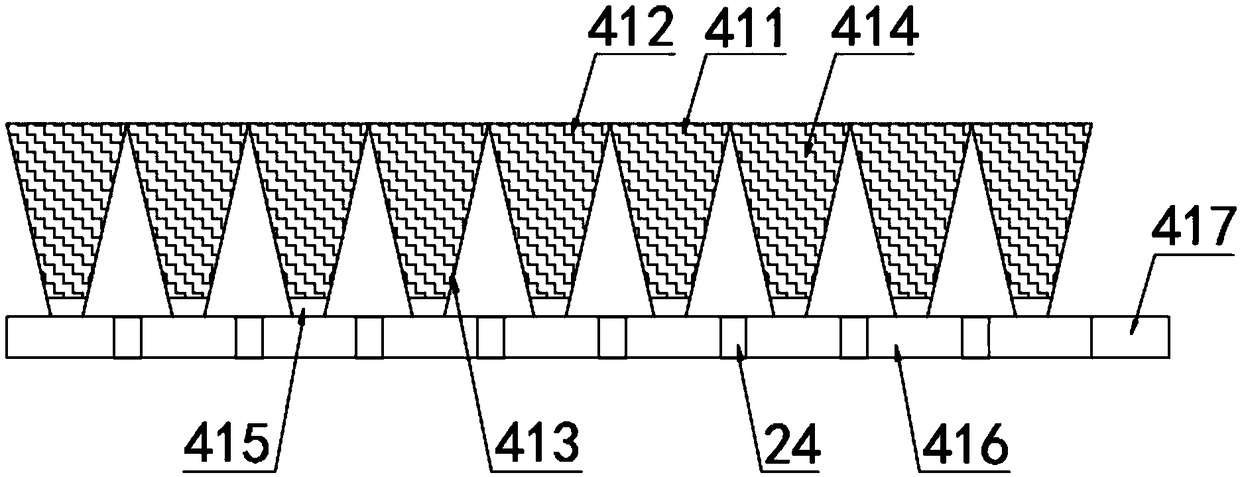

[0039] according to Figure 1-4 The shown sewage treatment system for a line factory includes a buffer tank 1, a floating filter tank 2, an extended flocculation tank 3, a multi-stage filter tank 4, and a PLC controller 5 for controlling the entire system. The extended flocculation tank 3 The input end is connected with the neutralization tank 6 and the dosing tank 7 through the shunt pipe 10, and the neutralization tank 6 and the dosing tank 7 are arranged on the top of the extension flocculation tank 3, and the input end of the multi-stage filter tank 4 is passed through the intake and exhaust Pipe 11 is connected with high-temperature steam tank 8 and dilute acid regeneration tank 9;

[0040] The buffer tank 1 is arranged on the top of the fluff filter tank 2 and communicates with the fluff filter tank 2. The inside of the fluff filter tank 2 is provided with a multi-layer filter screen 12, and one side of the bottom of the fluff filter tank 2 is provided with There is a s...

Embodiment 2

[0055] according to figure 1 As shown in a sewage treatment system for a wire manufacturing factory, a sewage distribution bucket 22 is arranged on the top of the inner cavity of the floating filter tank 2, and the cross section of the sewage distribution bucket 22 is set as an isosceles trapezoid, and the top of the sewage distribution bucket 22 is Connected to the outlet of the buffer tank 1, the bottom surface of the sewage distribution bucket 22 is evenly provided with a plurality of drainage holes;

[0056] The multi-layer filter screen 12 is evenly distributed up and down, the cross section of the filter screen 12 is set to be arc-shaped, and one end away from the sealed impurity removal door 13 is higher than the other end, and the sealed impurity removal door 13 and the floating hair filter tank 2 pass through hinge connection;

[0057] The air intake pipe 11 includes a vertical pipe and a plurality of horizontal pipes, and the plurality of horizontal pipes are respec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com