Bio-organic fertilizer

A bio-organic fertilizer and bacterial strain technology, applied in the field of bio-organic fertilizer, can solve the problems that bio-organic fertilizer cannot meet the use requirements, cannot meet the use requirements, and the cost of rapeseed meal is high, so as to improve soil physical and chemical biological properties, improve pH, increase The effect of fertility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] A bio-organic fertilizer, characterized in that it is made of the following components in parts by weight: 32 parts of cow dung, 22 parts of pig manure, 22 parts of straw, 12 parts of weeds, 11 parts of peanut shells, 12 parts of chicken feathers, algae mud 6 parts, 6 parts of rapeseed meal, 4 parts of quicklime, 11 parts of mint leaves, 2 parts of EM strain, 50 parts of water, 3 parts of sugar, 9 parts of lavender.

[0029] The straw adopts the straw of bean plants, such as soybean straw and mung bean straw.

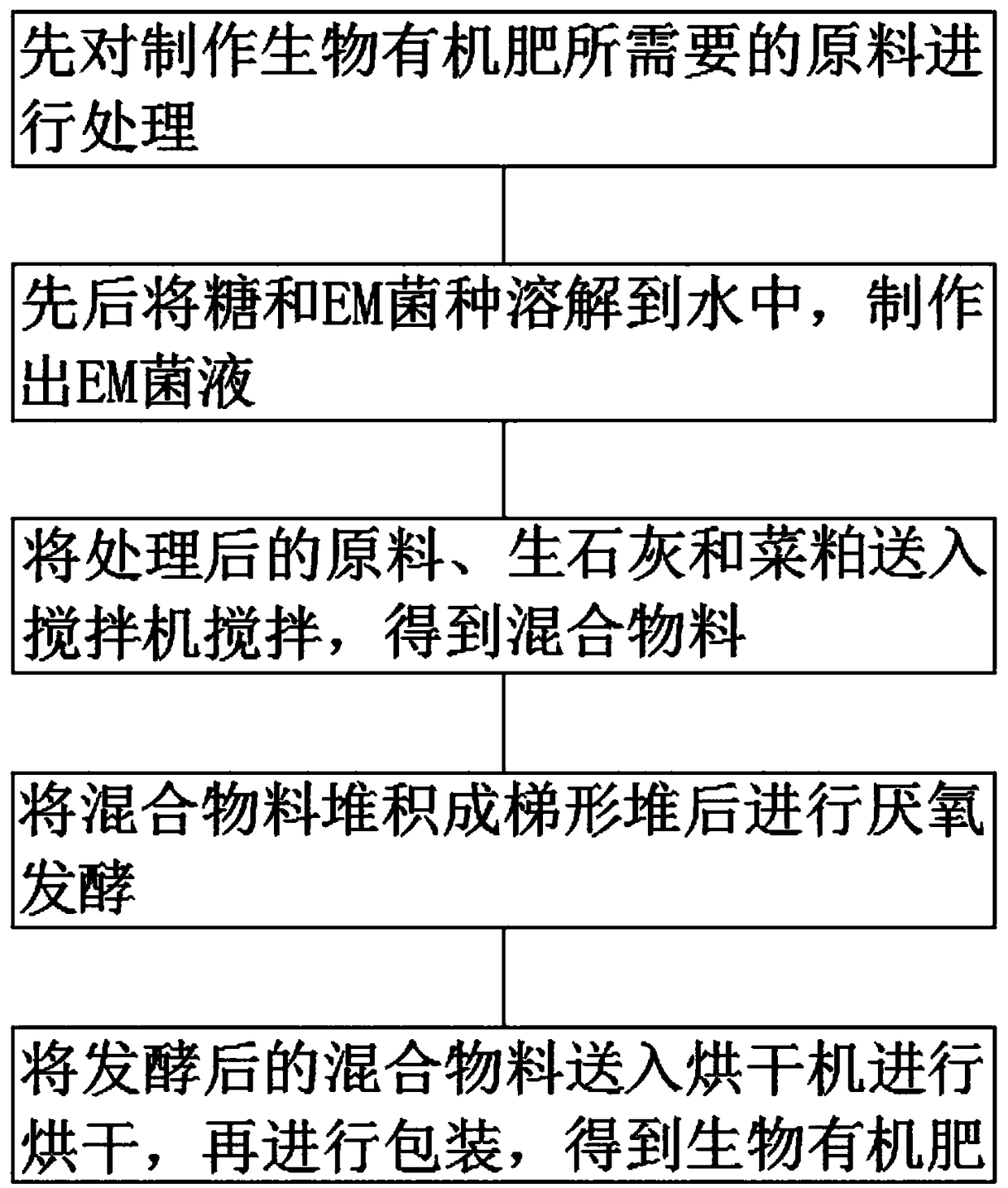

[0030] The preparation method of biological organic fertilizer comprises the following steps:

[0031] (1) First process the raw materials required in the production process of bio-organic fertilizers. The raw materials to be processed include cow dung, pig manure, straw, weeds, peanut shells, chicken feathers, algae mud, mint leaves and lavender, cow dung and pigs The manure treatment process is:

[0032] ①. First, the cow dung, pig manure and algae mud are se...

Embodiment 2

[0040] A bio-organic fertilizer, characterized in that it is made of the following components in parts by weight: 34 parts of cow dung, 25 parts of pig manure, 30 parts of straw, 15 parts of weeds, 12 parts of peanut shells, 15 parts of chicken feathers, algae mud 8 parts, 7 parts of rapeseed meal, 5 parts of quicklime, 12 parts of mint leaves, 2 parts of EM strain, 55 parts of water, 3 parts of sugar, 10 parts of lavender.

[0041] The straw adopts the straw of bean plants, such as soybean straw and mung bean straw.

[0042] The preparation method of biological organic fertilizer comprises the following steps:

[0043] (1) First process the raw materials required in the production process of bio-organic fertilizers. The raw materials to be processed include cow dung, pig manure, straw, weeds, peanut shells, chicken feathers, algae mud, mint leaves and lavender, cow dung and pigs The treatment process of manure is, the treatment process of cow manure and pig manure is:

[00...

Embodiment 3

[0052] A bio-organic fertilizer, characterized in that it is made of the following components in parts by weight: 36 parts of cow dung, 28 parts of pig manure, 36 parts of straw, 18 parts of weeds, 14 parts of peanut shells, 18 parts of chicken feathers, algae mud 9 parts, 8 parts of rapeseed meal, 4 parts of quicklime, 14 parts of mint leaves, 2 parts of EM strain, 60 parts of water, 3 parts of sugar, 11 parts of lavender.

[0053] The straw adopts the straw of bean plants, such as soybean straw and mung bean straw.

[0054] The preparation method of biological organic fertilizer comprises the following steps:

[0055] (1) First process the raw materials required in the production process of bio-organic fertilizers. The raw materials to be processed include cow dung, pig manure, straw, weeds, peanut shells, chicken feathers, algae mud, mint leaves and lavender, cow dung and pigs The treatment process of manure is, the treatment process of cow manure and pig manure is:

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com