Electrochromic polymer material based on combined strategy and preparation of electrochromic device

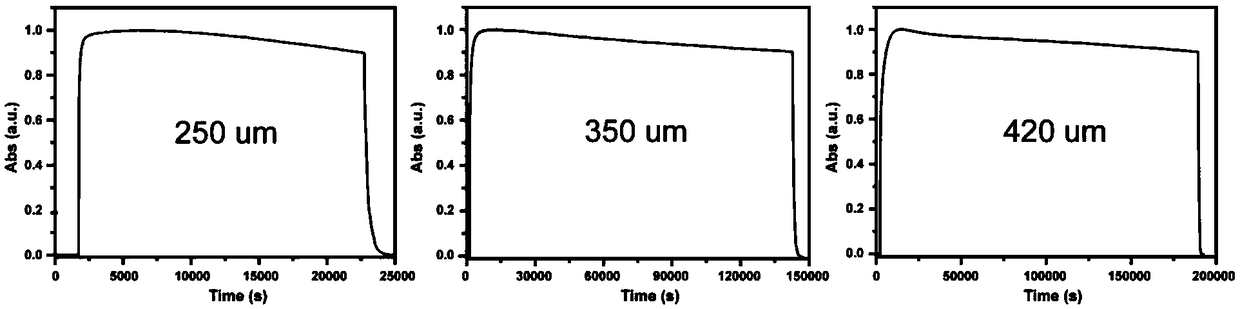

A technology of electrochromic devices and polymer materials, applied in the field of materials, can solve the problems of low color contrast, slow response speed, long fading time, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

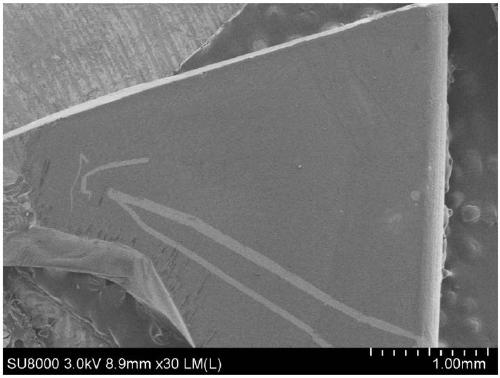

Image

Examples

Embodiment 1

[0051] In this embodiment, formula VI-1 is used as the electrochromic polymer, 1-butyl-3-methylimidazolium hexafluorophosphate is used as the electrolyte, and the two are mixed as an electrochromic polymer material based on a combination strategy. Acetonitrile was used as solvent. Wherein formula Ⅵ-1 is R in formula Ⅵ 1 , R 3 is N,N-diethyl, R 2 , R 4 , R 5 , R 6 is hydrogen, Y is oxygen, Ar is a benzene ring, Z 1 is methyl, P is polymethyl methacrylate, its structural formula is shown in formula VI-1, the preparation of electrochromic medium: 0.1mol of 1-butyl-3-methylimidazolium hexafluorophosphate as electrolyte, 400mg VI -1, dilute to 10mL with acetonitrile.

[0052]

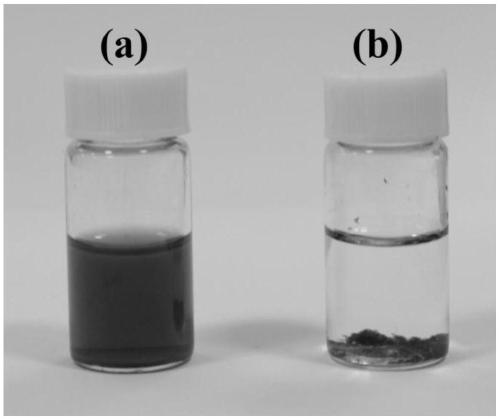

[0053] Preparation of electrochromic device: Spin-coat the above electrochromic medium onto a clean ITO-1 electrode, and then assemble it into an electrochromic device. Under the condition of positive voltage +1.5V, the device consists of Colorless and transparent to pink; under a negative voltage...

Embodiment 2

[0057] In this embodiment, formula I-1 is used as the electrochromic polymer, lithium perchlorate is used as the electrolyte, the two are mixed as the electrochromic polymer material based on the combination strategy, and acetone is used as the solvent. Wherein formula I-1 is R in formula I 1 , R 3 is aminoethyl, R 2 , R 4 , R 5 , R 6 is hydrogen, Y is dimethyl silicon, Ar is a naphthalene ring, Z 1 is methyl, P is polyethylene, and its structural formula is shown in formula VI-1. Electrochromic medium preparation: 0.8g lithium perchlorate as electrolyte, 0.4g I-1, and dilute to 10mL with acetone.

[0058]

[0059] Preparation of electrochromic device: Spin-coat the above electrochromic medium onto a clean ITO-1 electrode, and then assemble it into an electrochromic device. The electrochromic device is under a positive voltage of +1.5V, and the device is made of The color becomes transparent to blue; under the negative voltage -1.20V, the blue becomes colorless and tr...

Embodiment 3

[0061] In this embodiment, formula II-1 is used as the electrochromic polymer, lithium tetrafluoroborate is used as the electrolyte, the two are mixed as the electrochromic polymer material based on the combination strategy, and dimethylacetamide is used as the solvent. Wherein formula Ⅱ-1 is R in formula Ⅱ 1 , R 3 is N,N-diethyl, R 2 , R 4 is hydroxyl, R 5 , R 6 is hydrogen, Ar is a benzene ring, Z 1 is H, P is polyamide, and its structural formula is shown in II-1 below. Preparation of electrochromic medium: Weigh 0.27g of lithium tetrafluoroborate, 0.28g of II-1 molecules, and dilute to 10mL with dimethylacetamide.

[0062]

[0063] Preparation of electrochromic device: Spin-coat the above electrochromic medium onto a clean ITO-1 electrode, and then assemble it into an electrochromic device. The electrochromic device is under a positive voltage of +1.5V, and the device is made of The color becomes transparent to purple; under the negative voltage of -1.2V, the purp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com