Cable filling strip with anti-electromagnetic interference function and excellent heat conduction property and preparation method thereof

An anti-electromagnetic interference and cable filling technology, applied in the field of polymer materials, can solve the problems of poor thermal conductivity and heat dissipation performance of the filler strip, failure to provide anti-electromagnetic interference, complex production process, etc. The effect of large-scale production and simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] A cable filling strip with anti-electromagnetic interference function and excellent thermal conductivity, the cable filling strip includes the following components in terms of weight components: 20 parts of SBS thermoplastic elastomer, 20 parts of hydrogenated petroleum resin, and 20 parts of graphite powder , 10 parts of ferrite filter material, 10 parts of tributyl phosphate flame retardant, 10 parts of additives.

[0035] The preparation method of the above-mentioned cable filler strip with anti-electromagnetic interference function and excellent thermal conductivity comprises the following steps:

[0036] 1) Add thermoplastic elastomers, hydrogenated petroleum resins, flame retardants, and additives into the kneader, control the temperature in the kettle to 100°C, rotate at a speed of 40r / min, and knead at a low speed to obtain a flame-retardant mixed colloid A;

[0037] 2) Add graphite powder evenly into the kneader, adjust the speed to 100r / min, carry out high-spe...

Embodiment 2

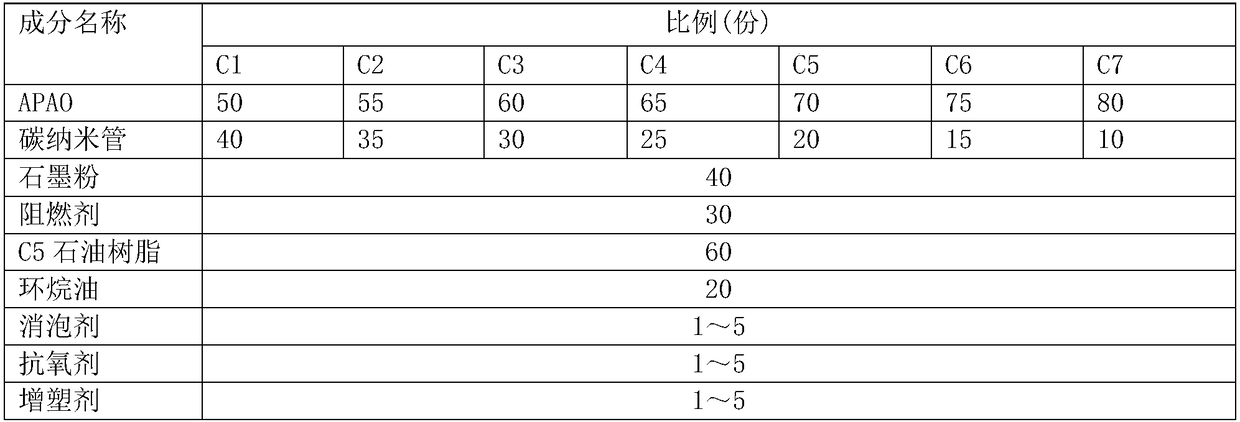

[0041] A cable filling strip with anti-electromagnetic interference function and excellent thermal conductivity, the cable filling strip includes the following components in terms of weight components: 100 parts of TPB thermoplastic elastomer, 100 parts of DCPD, 80 parts of graphite powder, carbon nano 50 parts of tube filter material, 50 parts of hydroxyaluminum flame retardant, and 50 parts of auxiliary agent.

[0042] The preparation method of the above-mentioned cable filler strip with anti-electromagnetic interference function and excellent thermal conductivity comprises the following steps:

[0043] 1) Add thermoplastic elastomer, DCPD, flame retardant, and additives into the kneader, control the temperature in the kettle to 200°C, rotate at 40r / min, and knead at a low speed to obtain flame-retardant mixed colloid A;

[0044] 2) Add graphite powder evenly into the kneader, adjust the rotating speed to 200r / min, carry out high-speed dispersion mixing, and mix and stir for...

Embodiment 3

[0048] A cable filling strip with anti-electromagnetic interference function and excellent thermal conductivity, said cable filling strip includes the following components in terms of weight components: 60 parts of TPEE thermoplastic elastomer, 80 parts of C5 hydrogenated petroleum resin, 50 parts of graphite powder 15 parts of FeCuSiBCV metal powder filter material, 30 parts of melamine cyanuric acid flame retardant, and 25 parts of additives.

[0049] The preparation method of the above-mentioned cable filler strip with anti-electromagnetic interference function and excellent thermal conductivity comprises the following steps:

[0050] 1) Add thermoplastic elastomers, petroleum resins, flame retardants, and additives into the kneader, control the temperature in the kettle to 150°C, rotate at a speed of 60r / min, and knead at a low speed to obtain a flame-retardant mixed colloid A;

[0051] 2) Add graphite powder evenly into the kneader, adjust the rotating speed to 180r / min, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com