Electrochemical method for controlling activated dissolution of carbon steel grain boundary

An electrochemical and carbon steel technology, applied in the electrochemical field of controlling the activation and dissolution of carbon steel grain boundaries, can solve the problems of poor control effect and high control difficulty, and achieve the effect of effective control and reduced control difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

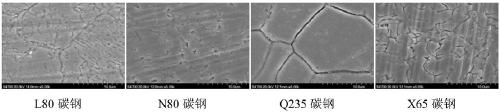

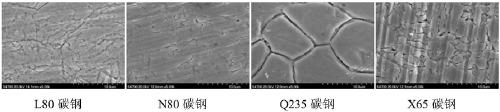

[0021] Taking L80 carbon steel, N80 carbon steel, Q235 carbon steel and X65 carbon steel as the research objects, the electrochemical method of controlling the activation and dissolution of carbon steel grain boundaries in this embodiment is used to conduct electrochemical analysis of grain boundaries and grains. State regulation. The electrochemical method for controlling activation and dissolution of carbon steel grain boundaries in this embodiment specifically includes the following steps:

[0022] 1) Electrolyte preparation: add 200 mL of sodium nitrite (NaNO 2 ) solution was added dropwise with nitric acid (HNO 3 ) to a pH value of 5, that is, the electrolyte solution for controlling the activation and dissolution of carbon steel grain boundaries in this embodiment;

[0023] 2) In the electrolyte for controlling the activation and dissolution of carbon steel grain boundaries in this embodiment, a potentiodynamic scan is applied to the carbon steel at a rate of 0.1 mV / s ...

Embodiment 2

[0027] Taking L80 carbon steel, N80 carbon steel, Q235 carbon steel and X65 carbon steel as the research objects, the electrochemical method of controlling the activation and dissolution of carbon steel grain boundaries in this embodiment is used to conduct electrochemical analysis of grain boundaries and grains. State regulation. The electrochemical method for controlling activation and dissolution of carbon steel grain boundaries in this embodiment specifically includes the following steps:

[0028] 1) Electrolyte preparation: add 200 mL of sodium nitrite (NaNO 2 ) solution was added dropwise with nitric acid (HNO 3 ) to a pH value of 4, that is, the electrolyte solution for controlling the activation and dissolution of carbon steel grain boundaries in this embodiment;

[0029] 2) In the electrolyte for controlling the activation and dissolution of carbon steel grain boundaries in this embodiment, a potentiodynamic scan is applied to the carbon steel at a rate of 0.1 mV / s ...

Embodiment 3

[0033] Taking L80 carbon steel, N80 carbon steel, Q235 carbon steel and X65 carbon steel as the research objects, the electrochemical method of controlling the activation and dissolution of carbon steel grain boundaries in this embodiment is used to conduct electrochemical analysis of grain boundaries and grains. State regulation. The electrochemical method for controlling activation and dissolution of carbon steel grain boundaries in this embodiment specifically includes the following steps:

[0034] 1) Electrolyte preparation: add 200 mL of sodium nitrite (NaNO 2 ) solution was added dropwise with nitric acid (HNO 3 ) to a pH value of 3, that is, the electrolyte solution for controlling the activation and dissolution of carbon steel grain boundaries in this embodiment;

[0035] 2) In the electrolyte for controlling the activation and dissolution of carbon steel grain boundaries in this embodiment, a potentiodynamic scan is applied to the carbon steel at a rate of 0.1 mV / s ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com