Anti-weft oblique processing method for denim fabric with bamboo joint effect

A processing method and anti-weft deflection technology, applied in fabric surface trimming, adhesive additives, textiles and papermaking, etc., can solve the problems of not having much effect, insufficient electric pulse signal, and unsatisfactory effect, etc., to achieve Reliable support, easy removal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] 2. The preparation method of the adhesive is:

[0035] (1) Preparation of carbon airgel dispersion: mix 1 part of carbon aerogel, 1 part of lecithin, and 2 parts of water in parts by mass, and ultrasonically oscillate for more than 10 minutes to obtain the product.

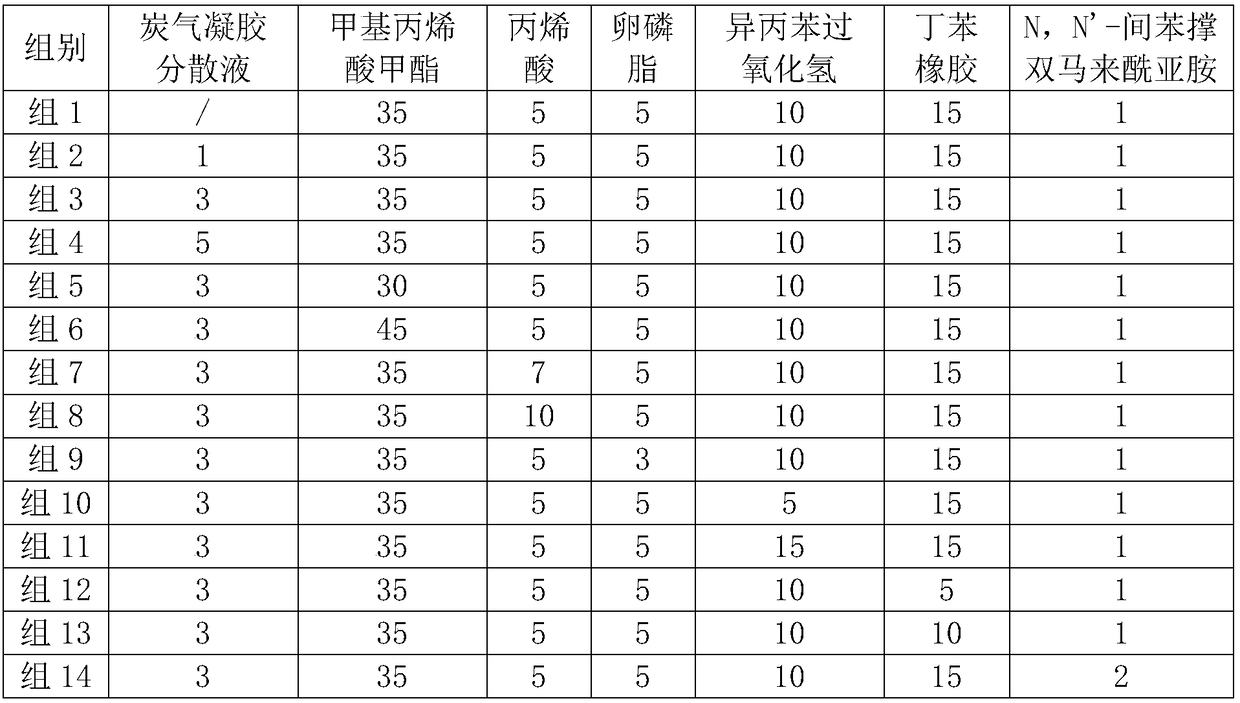

[0036] (2) According to parts by mass, mix 30-45 parts of methyl methacrylate, 5-10 parts of acrylic acid, 40-60 parts of deionized water, and 3-5 parts of lecithin, and then add iso 5-15 parts of propylbenzene hydrogen peroxide, 5-15 parts of styrene-butadiene rubber, 1-5 parts of carbon airgel dispersion, 1-2 parts of N,N'-m-phenylene bismaleimide, mix well Then react at 35°C for 6-8 hours to obtain the desired adhesive.

[0037] 3. The method of preparing the easy-to-tear film is:

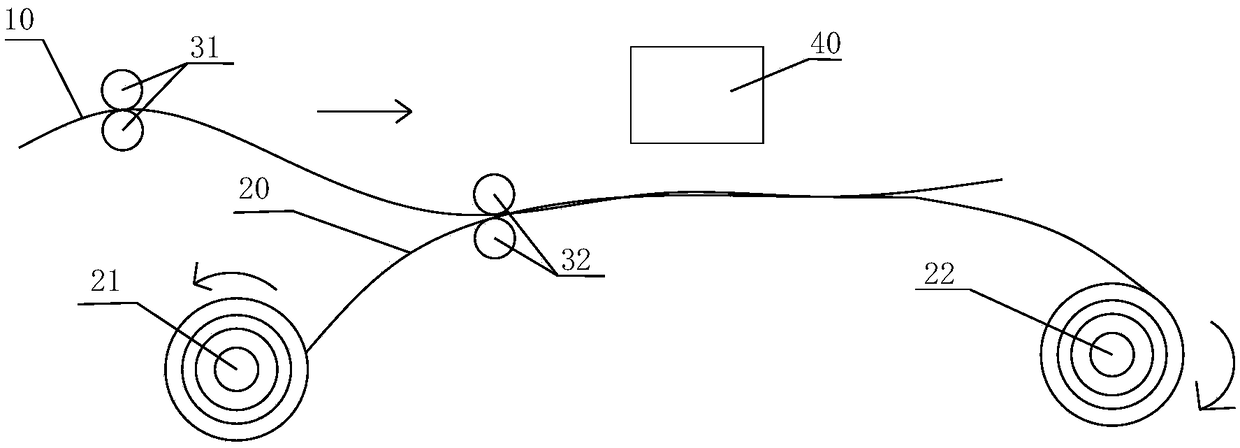

[0038] Apply the adhesive prepared in step 2 evenly on the base film at a speed of 150-200m / min by a coating machine. Position, as winding on the first reel 21, get final product.

[0039]Using the fabric dyed by the pres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com