Gas expansion pressure power machine

A gas expansion and power engine technology, applied in the field of mechanical power, can solve the problems of waste of resources, environment, large gas pollution, and high cost of use, and achieve the effects of reducing pollution, small size, and reducing carbon emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

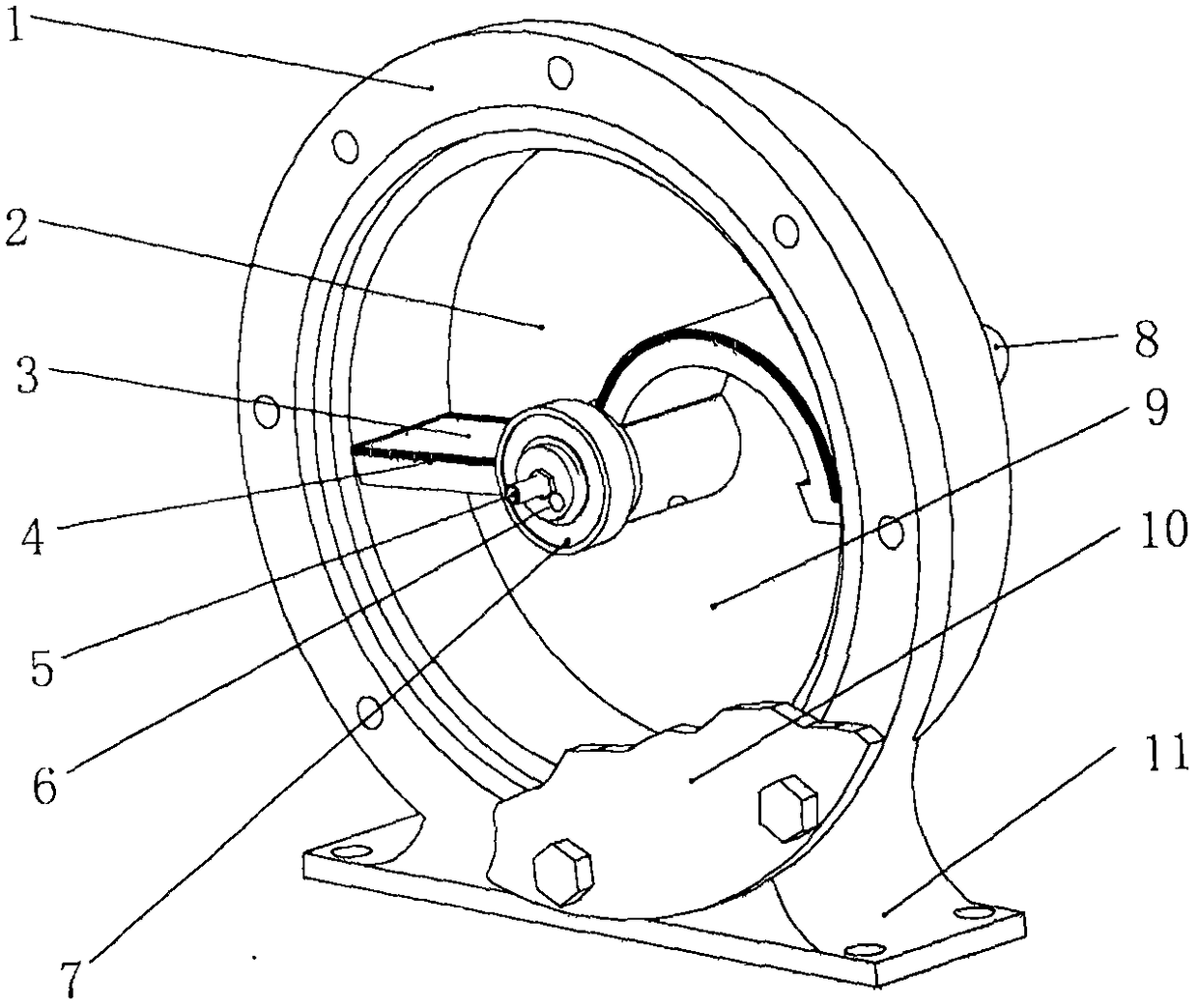

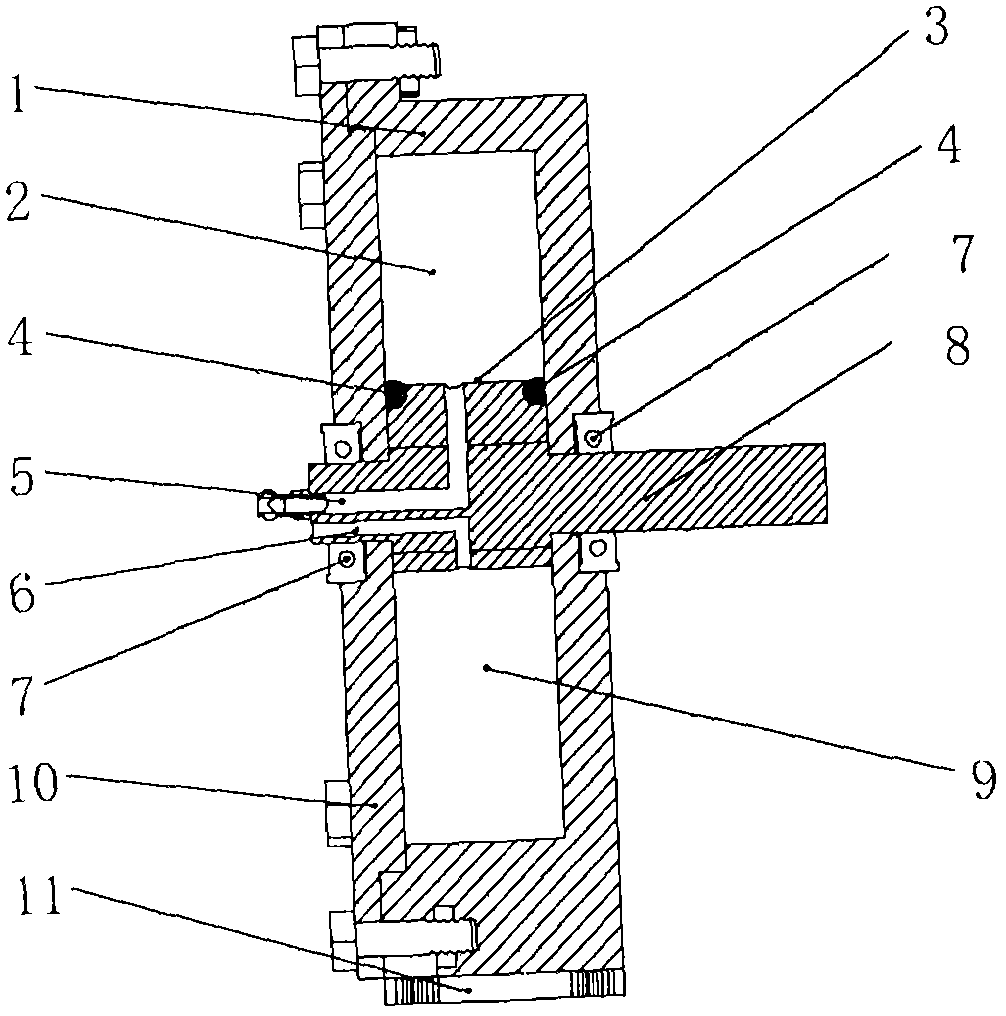

[0012] figure 1 , figure 2 Shown: the cylinder block 1 that one side is open cylinder is provided with the cylinder head 10 that is closed by several screws, and the center of circle of cylinder block 1 and cylinder head 10 is provided with the bearing seat that installs bearing 7 outside, and cylinder block 1 and cylinder The center of the cover 10 is provided with a through rotating shaft 8, one of the two ends of the rotating shaft 8 is a power output connection end, and the other end is provided with a high-pressure air inlet 5 with a one-way high-pressure air inlet nozzle at the center of the rotating shaft 8. The side of the hole 5 is provided with a normal pressure ventilation hole 6, and the rotating shaft 8 in the cylinder body 1 is fixed with a partition 3 that can drive the rotating shaft 8 to rotate. Two sides, one side is the plane another side is the convex surface of semicircle, thus a cylindrical air chamber body in the cylinder block 1 is divided into two se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com