Application of sodium bisulfide as plant stress-resisting agent

A plant stress resistance, sodium hydrosulfide technology, applied in the directions of plant growth regulators, plant growth regulators, applications, etc., can solve problems such as the influence of wax synthesis on the surface of guard cells, and achieves low cost, good water solubility, and preparation. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

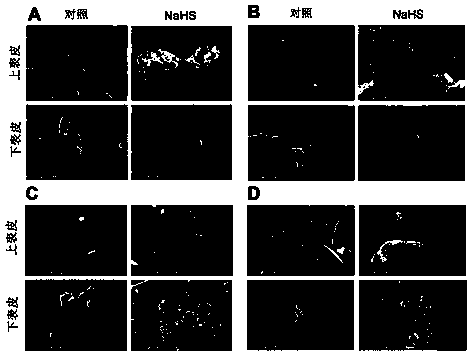

[0022] Weigh sodium hydrosulfide monohydrate (NaHS·H 2 O) Add water to prepare 50 μmol L -1 The aqueous solution, the treatment solution is ready-to-use. Tomatoes, cucumbers, tobacco, and Arabidopsis thaliana, which had grown for 4 weeks, continued to dry after watering enough. During this process, the prepared NaHS aqueous solution was fumigated, and fumigated once every other day for 6 hours each time. After 10 days, the tenderest first leaf was taken and fixed, made into slices, and observed with a scanning electron microscope.

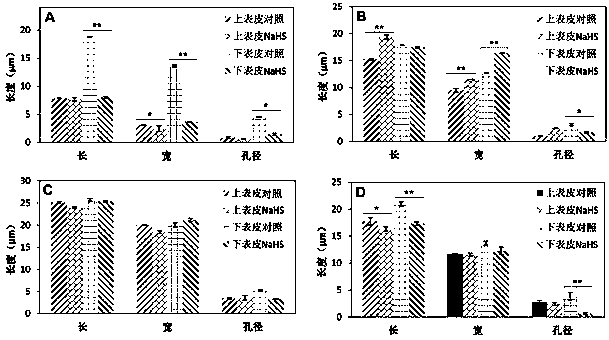

[0023] Such as figure 1 As shown, A is the upper and lower epidermis of tomato; B is the upper and lower epidermis of cucumber; C is the upper and lower epidermis of tobacco; D is the upper and lower epidermis of Arabidopsis. The four materials were divided into control group (natural state, without sodium hydrogen sulfide treatment) and treatment group, and continued drought after sufficient watering. During the period, the treatment group was...

Embodiment 3

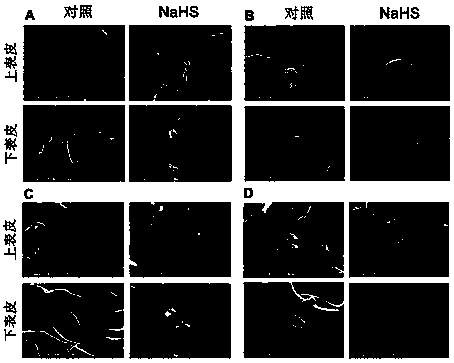

[0028] Embodiment 3. Weigh sodium hydrosulfide monohydrate (NaHS·H 2 O) Add water to prepare 100 μmol L -1 The aqueous solution, the treatment solution is ready-to-use. Tomatoes, cucumbers, tobacco, and Arabidopsis thaliana, which had grown for 4 weeks, continued to dry after watering enough. During this process, the prepared NaHS aqueous solution was fumigated, and fumigated once every other day for 6 hours each time. After 10 days, the tenderest first leaf was taken and fixed, made into slices, and observed with a scanning electron microscope.

[0029] Such as Figure 4 Shown are the upper and lower epidermis of four materials: A is the upper epidermis; B is the lower epidermis; C is the upper epidermis; D is the lower epidermis. It was found that the stomatal density of the leaves of the treatment group fumigated by NaHS was significantly reduced. After statistical analysis, the results showed that the number of guard cells in the three materials except tobacco decreas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com