Fire prewarning and fire extinguishing system based on industrial CO2 collection capable of relieving climate change

A technology of fire early warning and fire extinguishing system, which is applied in the direction of fire alarm and fire rescue based on smoke/gas action, and can solve problems such as firefighters and facilities not being in place in time, threatening the safety of factories and forests, and fire expansion, etc., to achieve The effect of preventing major accidents, reducing air pollution, and completely separating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

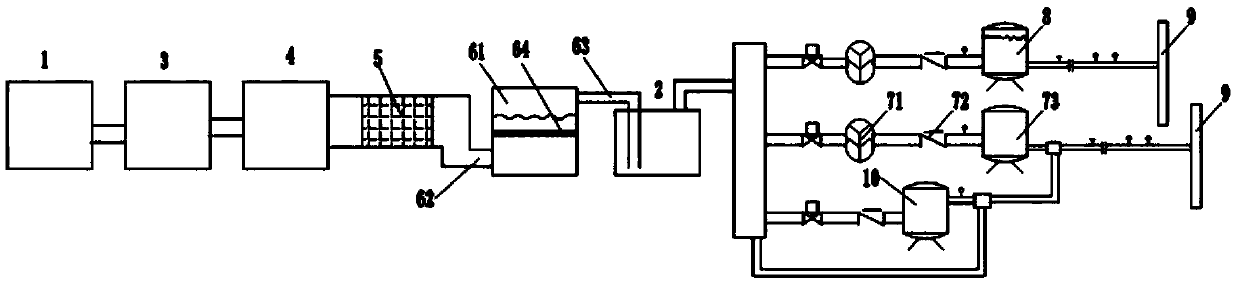

[0025] An industrial CO-based solution for mitigating climate change 2Collection fire early warning fire extinguishing system, the collection device 1 is used to gather and guide the exhaust gas to the purification process, collect it through the collection cover and exhaust fan installed at the industrial air sewage outlet, and then enter the dust filter device 3 from the exhaust fan outlet to filter The dust is decomposed into harmful gas through the combustion purification device 4 . The exhaust gas drawn from the combustion purification device 4 is introduced into the cold catalyst filter device 5 to further decompose harmful gases. The cold catalyst filtering device 5 adopts a multi-layer filter screen structure and can be directly installed in the pipeline. After passing through the cold catalyst filter device 5, the exhaust gas is basically p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com