Screening and separating system for efficiently separating ore pulp and granular medium

A technology of granular media and separation system, applied in the fields of filtration and separation, separation methods, chemical instruments and methods, etc., can solve the problems of expensive equipment cost, violation of cost control of mining enterprises, easy blocking of sieve holes by granular media, etc., and achieve low cost. effect of input

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

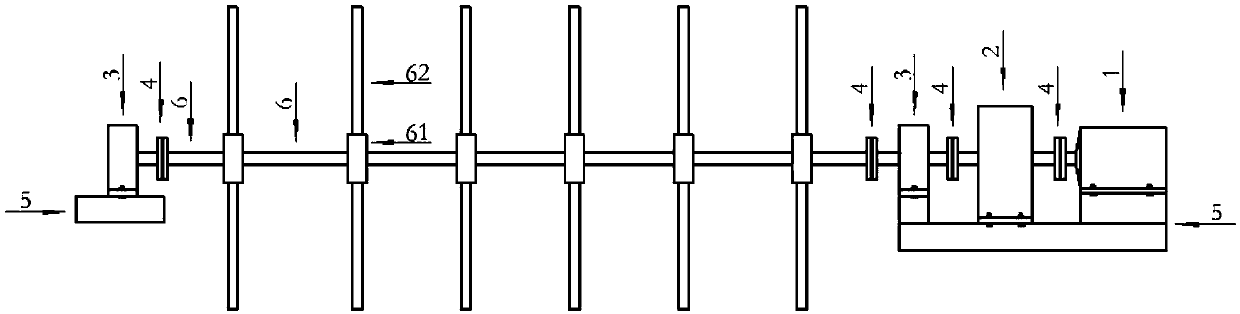

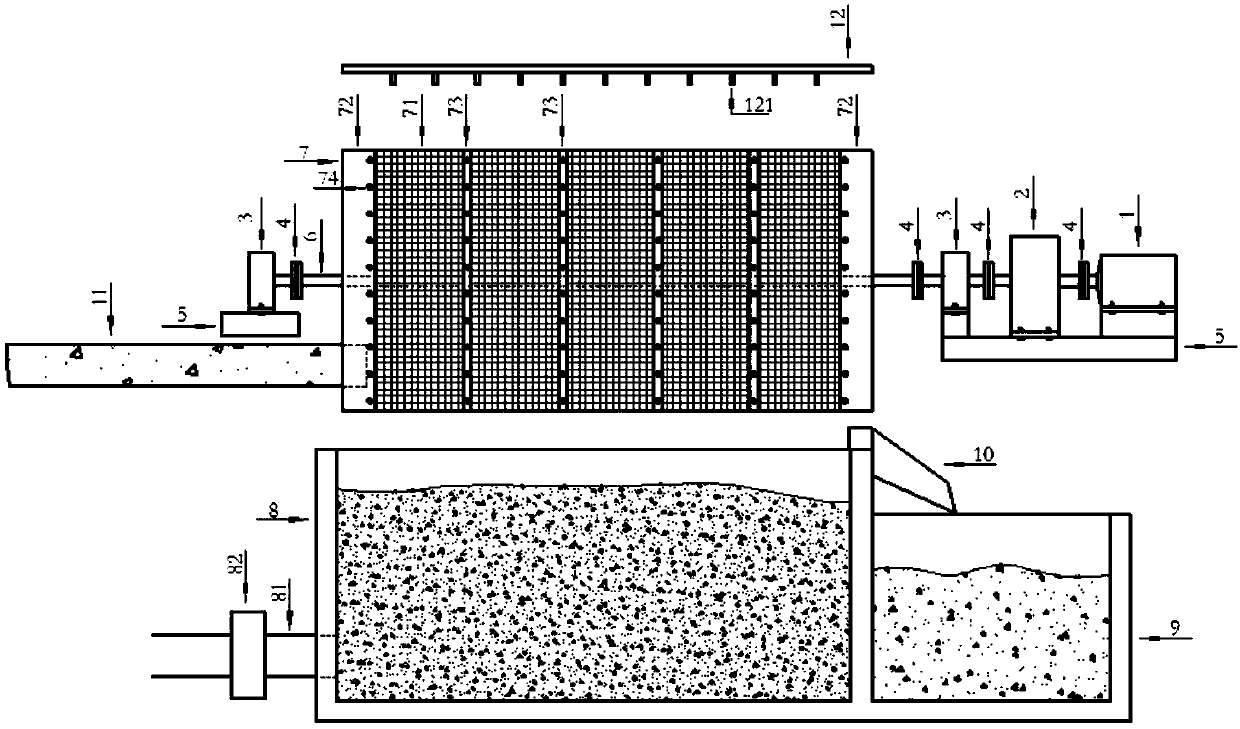

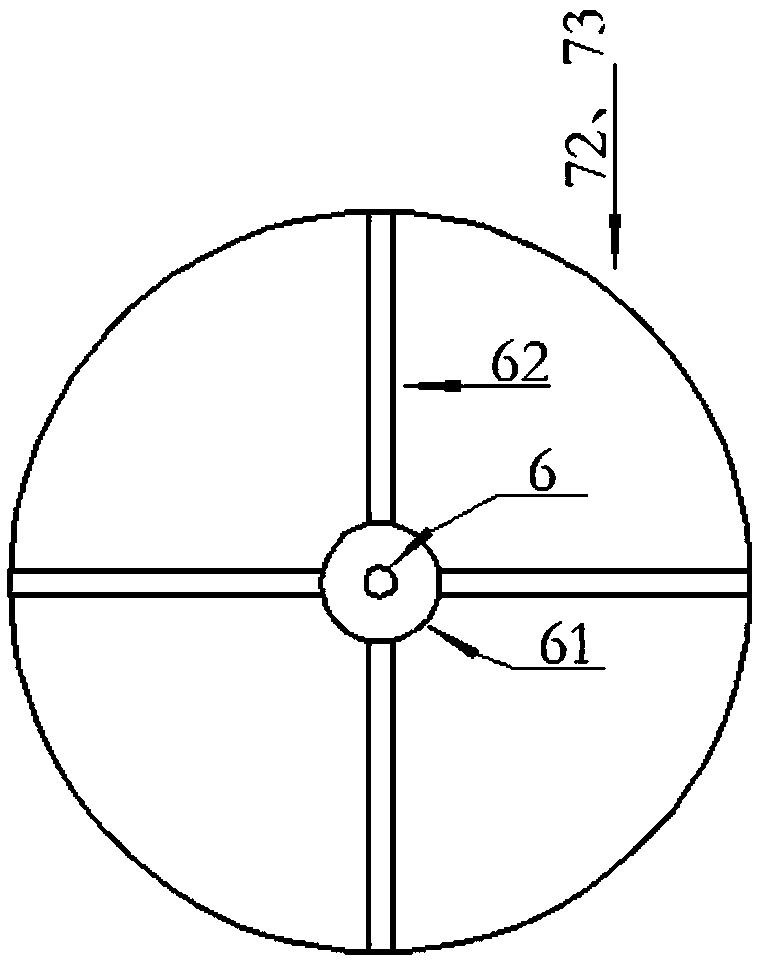

[0029] Such as figure 1 - image 3 As shown, the screening and separation system for efficiently separating pulp and granular media in the present invention includes a screening drum 7 , a power transmission system, a pulp pool 8 and a sand pile pool 9 . The power transmission system is connected to each other through the motor 1, the reducer 2, the transmission shaft 6, the coupling 4 and the base 5, and six flywheels 61 are installed on the transmission shaft 6, and the distance between the flywheels 61 is 450 mm, and 4 evenly welded on each flywheel 61 root support rods 62, and then the end arc plate 72 and the middle arc plate 73 are welded and fixed on the four support rods to form the outline of the screening drum 7, and finally the polyurethane screen 71 is fastened to the end arc plate 72 by connecting screws 74 And on the middle arc plate 73. The screening drum 7 has 5 sections in total, the screening drum has a length of 2500mm and a diameter of 1200mm, and the dis...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com