A kind of carbon monoxide removal catalyst and preparation method thereof

A carbon monoxide and catalyst technology, applied in the field of carbon monoxide removal catalyst and its preparation, can solve the problems of low catalytic efficiency, insufficient number of catalytic active centers, difficult active components in specific surface area, etc., and achieves improved catalytic activity, excellent sulfur resistance, pores Evenly distributed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

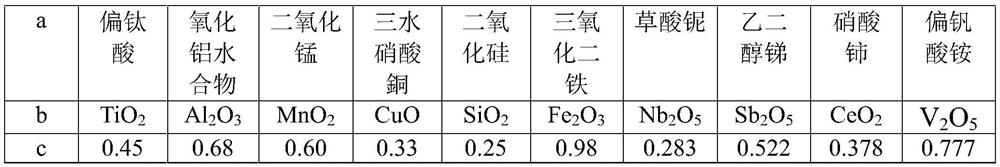

Image

Examples

preparation example Construction

[0047] B. Catalyst preparation and CO removal

[0048] Based on the preparation of 300g catalyst, the above-mentioned raw materials were used to prepare catalysts, and the CO removal rate of each catalyst was tested.

Embodiment 1

[0050] A preparation method of a carbon monoxide removal catalyst in this embodiment comprises the following steps:

[0051] (1) Get 266.7g of metatitanic acid after washing (accounting for 40% (W / W) of catalyst weight), then add commercial alumina hydrate 44.1g (accounting for 10% (W / W) of catalyst weight) Mixing; add manganese dioxide 150g (contained MnOx accounts for catalyst weight 30% (W / W)), then adds copper nitrate trihydrate 181.8g (converted copper oxide accounts for catalyst weight 20% (W / W)) Fully knead;

[0052] (2) Add 0.75g of scallop powder (pore-enlarging agent and lubricant) (accounting for 0.25% (W / W) of catalyst weight), glycerin (release agent) 1.5g (accounting for 0.5% of catalyst weight (W / W) ), ethanolamine 4.5g (accounting for 1.5% (W / W) of catalyst weight), PEO2.4g (accounting for 0.8% (W / W) of catalyst weight) and appropriate amount of deionized water, continue kneading; A honeycomb catalyst precursor with a size of 50mm×50mm×200mm (the size of the ...

Embodiment 2

[0058] A preparation method of a carbon monoxide removal catalyst in this embodiment comprises the following steps:

[0059] (1) Get 266.7g of metatitanic acid after washing (accounting for 40% (W / W) of catalyst weight), then add commercial alumina hydrate 44.1g (accounting for 10% (W / W) of catalyst weight) Mixing; Add manganese dioxide Manganese dioxide 125g (contained MnO Account for catalyst weight 25% (W / W)), add copper nitrate trihydrate 227.3g (converted copper oxide accounts for catalyst weight 25% (W / W) W)) fully kneading;

[0060] (2) Add 0.75g of CMC (pore expander and lubricant) (0.25% (W / W) of the catalyst weight), 1.5g of glycerin (release agent) (0.5% of the catalyst weight (W / W)) , ethanolamine 4.5g (accounting for 1.5% (W / W) of catalyst weight), PEO2.4g (accounting for 0.8% (W / W) of catalyst weight) and appropriate amount of deionized water, continue kneading; A honeycomb catalyst precursor of 50mm×50mm×200mm (the size of the honeycomb pores is 3mm×3mm);

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com