Lithium-sulfur battery electrolyte

A lithium-sulfur battery and electrolyte technology, applied in the field of lithium-sulfur battery electrolyte, can solve the problems of unfavorable commercialization of batteries and increased battery prices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

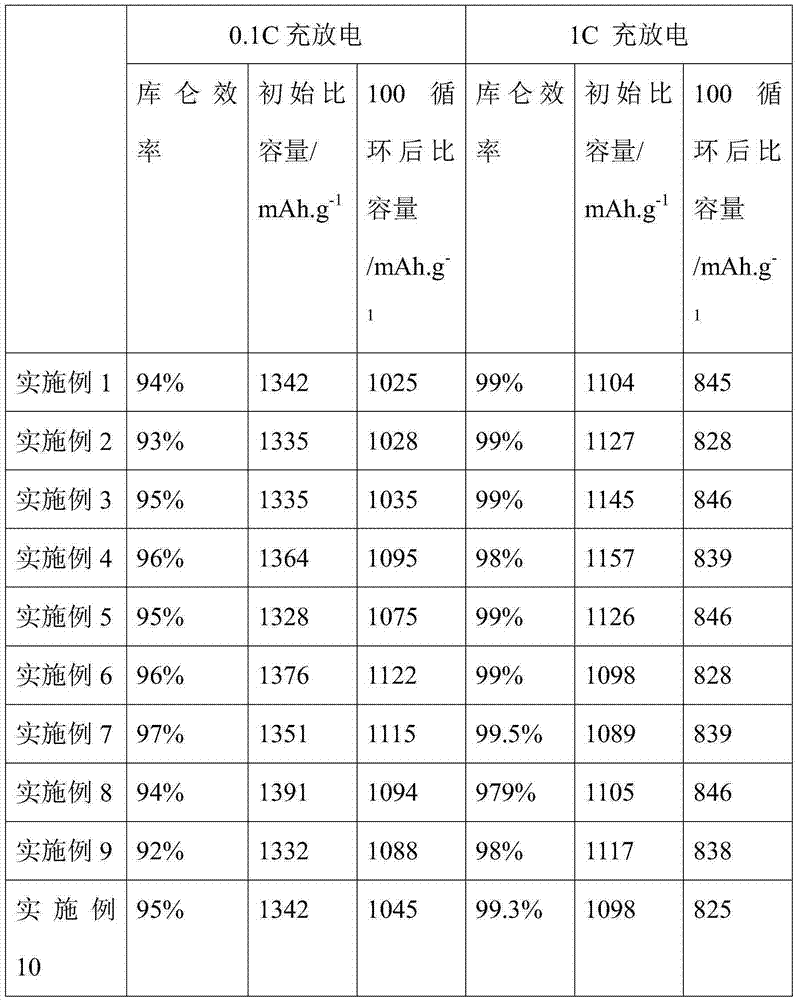

Examples

Embodiment 1

[0034] Electrolyte solution composition: straight-chain fatty ether is straight-chain fatty ether (1) (as shown in formula 1); lithium salt is LiN(SO3CF2CF3)2, concentration is 1mol / L;

[0035] The negative electrode of the lithium-sulfur battery is a lithium foil with a thickness of 50 microns, and the positive electrode is prepared by the following method: 30 parts by mass of Super P carbon, 60 parts by mass of elemental sulfur, and 10 parts by mass (solid content) of nitrile rubber emulsion Blend and apply to aluminum foil. The sulfur content in the positive electrode active layer after drying was 1.5 mg / cm2. The above-mentioned components were assembled together in a layered structure of positive electrode / diaphragm / negative electrode, and sealed after adding electrolyte at a rate of 30 microliters per square centimeter of positive electrode area. After standing still for 5 hours, the battery was charged and discharged at 0.1C and 1C, respectively, with respect to the mas...

Embodiment 2

[0037] The composition of the electrolyte solution: the straight-chain fatty ether is straight-chain fatty ether (2) (as shown in formula 1); the lithium salt is LiN(SO3CF2CF3)2, and the concentration is 1mol / L;

[0038] The negative electrode of the lithium-sulfur battery is a lithium foil with a thickness of 50 microns, and the positive electrode is prepared by the following method: 30 parts by mass of Super P carbon, 60 parts by mass of elemental sulfur, and 10 parts by mass (solid content) of nitrile rubber emulsion Blend and apply to aluminum foil. The sulfur content in the positive electrode active layer after drying was 1.5 mg / cm2. The above-mentioned components were assembled together in a layered structure of positive electrode / diaphragm / negative electrode, and sealed after adding electrolyte at a rate of 30 microliters per square centimeter of positive electrode area. After standing still for 5 hours, the battery was charged and discharged at 0.1C and 1C, respective...

Embodiment 3

[0040] The composition of the electrolyte solution: the straight-chain fatty ether is straight-chain fatty ether (3) (as shown in formula 1); the lithium salt is LiN(SO3CF2CF3)2, and the concentration is 1mol / L;

[0041] The negative electrode of the lithium-sulfur battery is a lithium foil with a thickness of 50 microns, and the positive electrode is prepared by the following method: 30 parts by mass of Super P carbon, 60 parts by mass of elemental sulfur, and 10 parts by mass (solid content) of nitrile rubber emulsion Blend and apply to aluminum foil. The sulfur content in the positive electrode active layer after drying was 1.5 mg / cm2. The above-mentioned components were assembled together in a layered structure of positive electrode / diaphragm / negative electrode, and sealed after adding electrolyte at a rate of 30 microliters per square centimeter of positive electrode area. After standing still for 5 hours, the battery was charged and discharged at 0.1C and 1C, respective...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com