Tire mold laser cleaning light path

A tire mold and laser cleaning technology, applied in the field of laser cleaning, can solve the problems of safety and environmental protection, long cleaning time, easy damage to mold precision, etc., to improve efficiency, avoid mold damage, and save standby time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

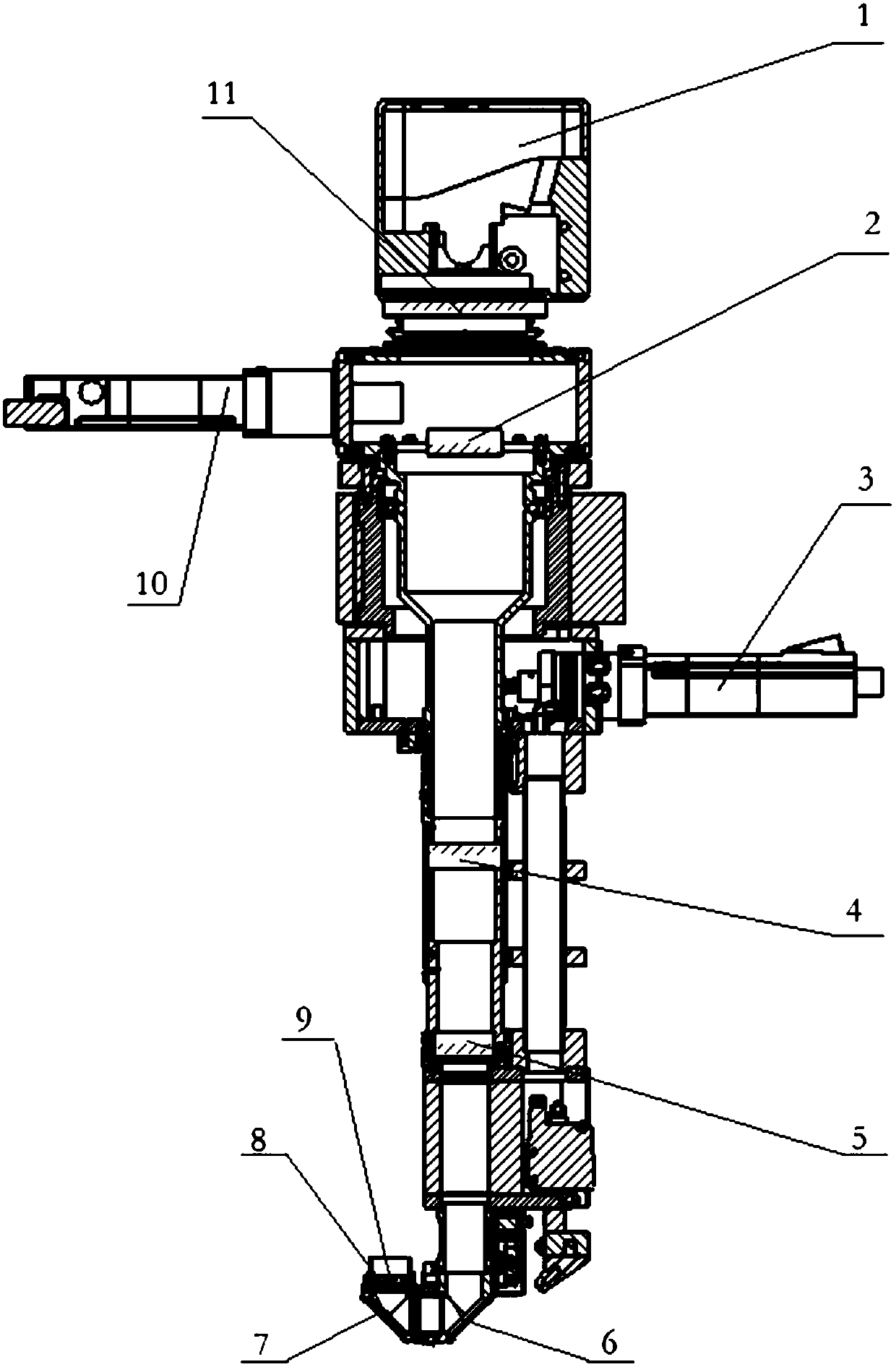

[0016] Attached below Figure 1-2 And embodiment further illustrate the present invention.

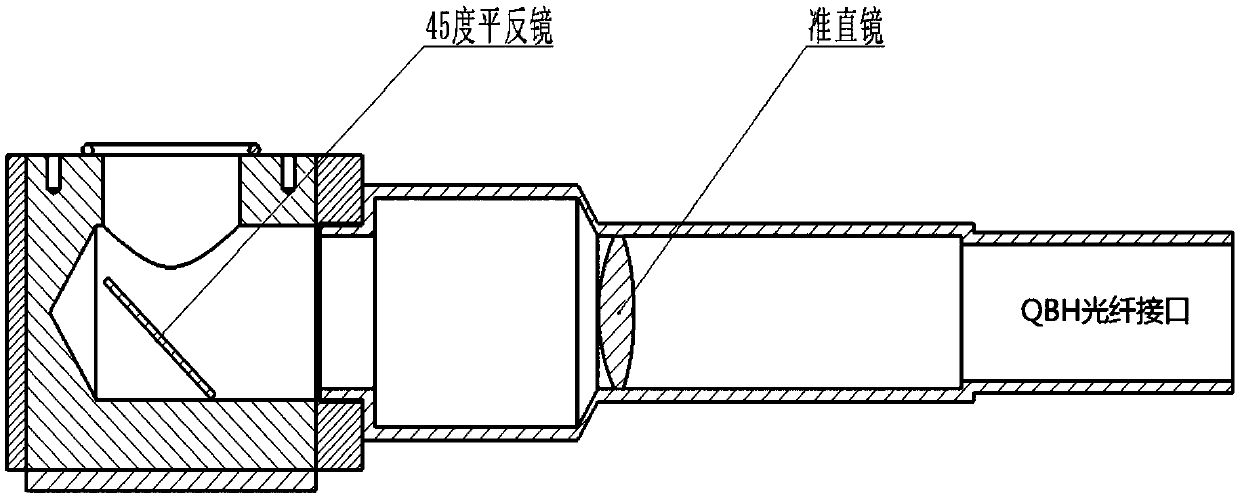

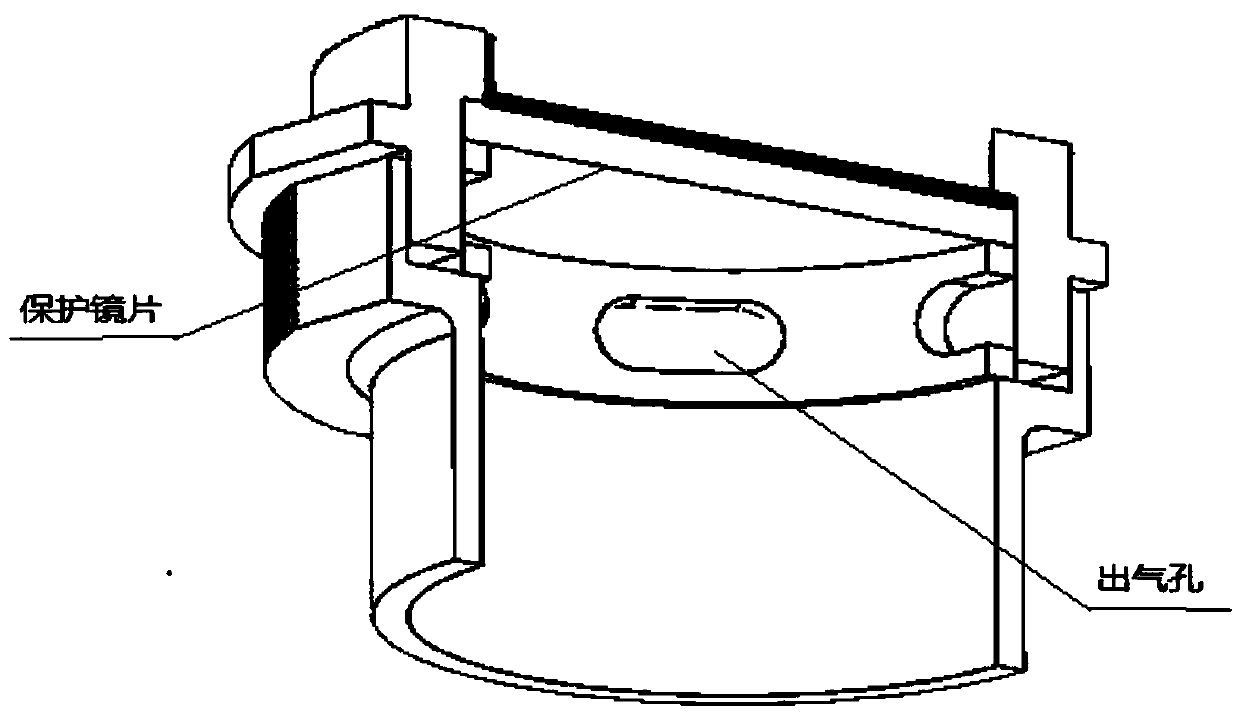

[0017] A tire mold laser cleaning optical path, the laser beam is transmitted through the optical fiber through the connection of the QBH interface, and the beam enters the optical path; the optical path includes a scanning vibrating mirror 1, a first plano-convex lens 2, a motor 3, a second plano-convex lens 4, and a double-convex lens 5, The first 45-degree flat mirror 6, the second 45-degree flat mirror 7, the protective lens 8, the gas protection device 9, the motor 10, the vibrating mirror window mirror 11; the beam enters the scanning vibrating mirror 1, and then the beam passes through the vibrating mirror window mirror 11. Transmission to the first plano-convex lens 2, with the convex surface facing upwards, converging the light beam to the focal point, then continuing to transmit and diverge, and passing it to the second plano-convex lens 4, with the convex surface facing down...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com