A tree whitening pulping box

A technology of whitening and tree brushing, applied in the field of pulp receiving box, can solve the problems of waste of resources, flowing mortar, low work efficiency, etc., and achieve the effect of improving efficiency, flexible operation and saving pulp and ash.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The invention will be further described below in conjunction with the accompanying drawings:

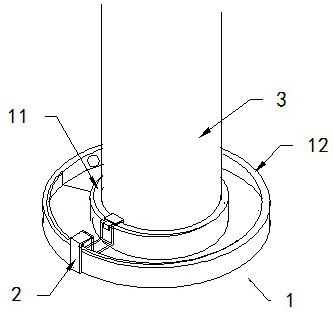

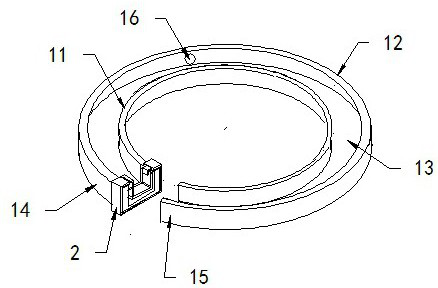

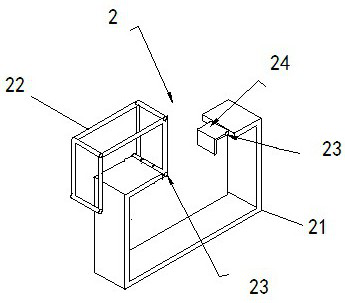

[0018] Such as figure 2 Shown: a tree whitening pulp receiving box, including an arc groove box 1 and a clamp 2.

[0019] 1. Arc groove box.

[0020] Such as figure 1 figure 2 As shown, the cross-section of the arc groove box 1 is in the shape of "凵", and its structure is that the bottom end between the inner ring plate 11 and the outer ring plate 12 is fixedly connected with a bottom plate 13, and the box body is a broken circular arc ring , the two ends are respectively a wide groove 14 and a narrow groove 15, the inner groove surface of the wide groove body corresponds to the shape and size of the outer groove surface of the narrow groove body, the narrow groove body 15 can be overlapped and built in the wide groove body 14, and the arc The groove box 1 can overlap and surround the outer periphery of the tree body 3. According to the diameter of the tree body, the ove...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com