High-compactness monocrystalline ternary cathode material, as well as preparation method and application thereof

A cathode material and high-pressure compaction technology, which is applied in the field of high-pressure compaction single crystal ternary cathode material and its preparation, can solve the problems of high energy consumption, complex synthesis process, labor-hour consumption, etc., and achieves energy consumption reduction, process simplification, The effect of a wide range of craftsmanship

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

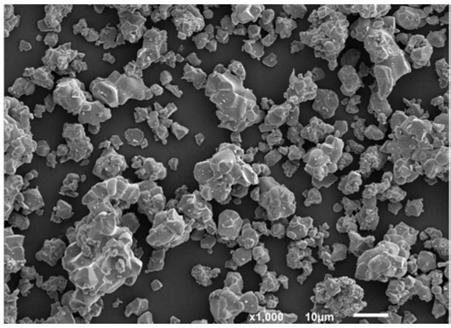

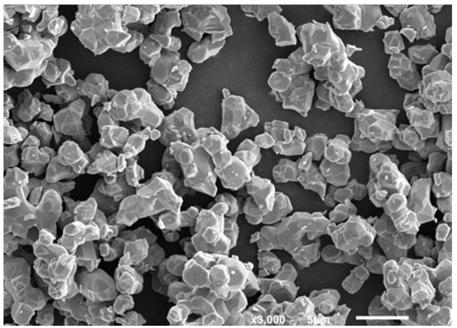

[0051] The first step: take the small particle ternary precursor Ni with the particle size satisfying D50=3.1μm 0.7 Co 0.1 Mn 0.2 (OH) 2 In an atmosphere furnace, the temperature was first heated to 400 °C for 6 h under the air atmosphere, and then continued to be heated to 900 °C for 12 h at a constant temperature of 3 °C / min; Oxide, its particle size D50=2.3μm;

[0052] The second step: take the large particle ternary precursor Ni with the particle size satisfying D50=13.4μm 0.7 Co 0.1 Mn 0.2 (OH) 2 In an atmosphere furnace, the temperature was first heated to 400 °C for 6 hours under an air atmosphere, and then continued to be heated to 940 °C for 16 hours at a constant temperature of 3 °C / min; Oxide, its particle size D50=5.2μm;

[0053] The third step: according to the mass ratio of large: small = 7:3, take the large and small single crystal ternary oxides with different particle sizes obtained from S2 and S1 and mix them evenly, and then mix them with Li with a m...

Embodiment 2

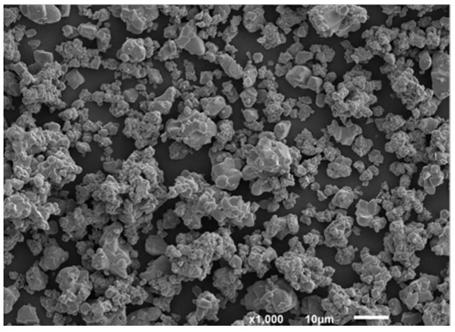

[0056] The difference from Example 1 is to mix large and small single crystal ternary oxides with a mass ratio of 5:5. Other experimental conditions are the same as those of Example 1. LiNi is obtained after sintering and cooling. 0.7 Co 0.1 Mn 0.2 O 2 High-pressure compacted single crystal ternary cathode material.

Embodiment 3

[0058] The difference from Example 1 is to mix large and small single crystal ternary oxides with a mass ratio of 3:7. Other experimental conditions are the same as in Example 1. LiNi is obtained after sintering and cooling. 0.7 Co 0.1 Mn 0.2 O 2 High-pressure compacted single crystal ternary cathode material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com