TPU blend and use thereof

A technology of blends and elastomers, applied in applications, household appliances, cleaning equipment, etc., can solve the problems of TPU wear resistance reduction, affect the mechanical properties and wear resistance of TPU products, reduce the wear resistance of TPU, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

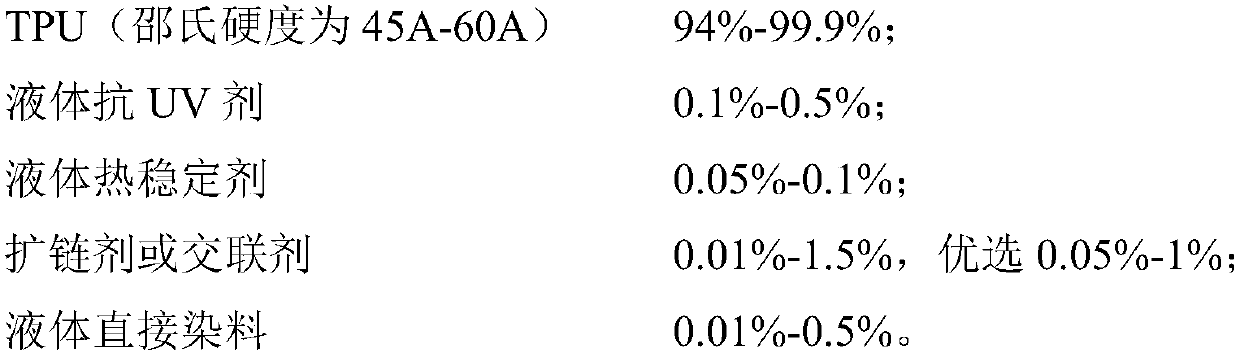

[0075] This embodiment provides an anti-yellowing, low-hardness and wear-resistant thermoplastic polyurethane elastomer blend. Its raw material formula is: 99.29kg TPU, 0.5kg 2-(2H-benzotriazole-2-yl)-6 -Dodecyl-4-methylphenol, 0.1kg bis(1,2,2,6,6-pentamethylpiperidinol) sebacate, 0.01kg 1,4-butanediol, 0.1kg Liquid Direct Blue. Among them, soft 45A12P of BASF Company was used as TPU, and commercially available chemical reagents were used as others.

[0076] After uniformly mixing the raw materials of the above-mentioned blend formulation, the granulated material is prepared by twin-screw extrusion. Carry out abrasion resistance test (test standard ISO4649-A) and anti-UV test (340nm, irradiance 0.89w / m2) to the prepared granulated material 2 , 24h), Shore hardness test (according to ASTM D1415 standard) and other performance tests, the measured data are wear amount 38mm 3 , Shore hardness 55A, color difference change △E=6.4.

Embodiment 2

[0078] This embodiment provides an anti-yellowing, low-hardness and wear-resistant thermoplastic polyurethane elastomer blend. Its raw material formula is: 99.74kg TPU, 0.1kg 2-(2H-benzotriazol-2-yl)-6 -Dodecyl-4-methylphenol, 0.05kg bis(1,2,2,6,6-pentamethylpiperidinol) sebacate, 0.1kg 1,4-butanediol, 0.01kg Liquid Direct Blue. Among them, soft 45A12P of BASF Company was used as TPU, and commercially available chemical reagents were used as others.

[0079] After uniformly mixing the raw materials of the above-mentioned blend formulation, the granulated material is prepared by twin-screw extrusion. Carry out abrasion resistance test (test standard ISO4649-A) and anti-UV test (340nm, irradiance 0.89w / m2) to the prepared granulated material 2 , 24h), Shore hardness test (according to ASTM D1415 standard) and other performance tests, the measured data are the wear amount of 34mm 3 , Shore hardness 57A, color difference change △E=6.1.

Embodiment 3

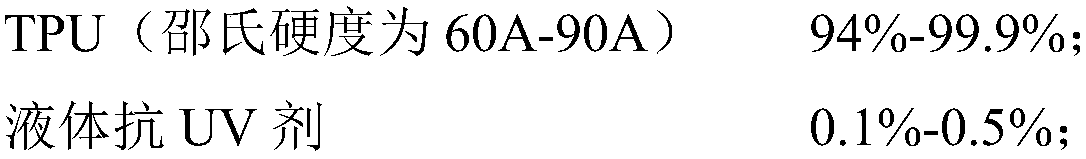

[0081] This embodiment provides an anti-yellowing, low-hardness and wear-resistant thermoplastic polyurethane elastomer blend. Its raw material formula is: 98.8kg TPU, 0.5kg 2-(2H-benzotriazol-2-yl)-6 - Dodecyl-4-methylphenol, 0.1kg bis(1,2,2,6,6-pentamethylpiperidinol) sebacate, 0.1kg blowing agent AC, 0.5kg liquid direct blue . Among them, WHT-1570IC from Yantai Wanhua Company was used for TPU, and commercially available chemical reagents were used for others.

[0082] After uniformly mixing the raw materials of the above-mentioned blend formulation, the granulated material is prepared by twin-screw extrusion. Carry out abrasion resistance test (test standard ISO4649-A) and anti-UV test (340nm, irradiance 0.89w / m2) to the prepared granulated material 2 , 24h), Shore hardness test (according to ASTM D1415 standard) and other performance tests, the measured data are wear amount 39mm 3 , Shore hardness 53A, change △E=5.8.

PUM

| Property | Measurement | Unit |

|---|---|---|

| wear volume | aaaaa | aaaaa |

| Shore hardness | aaaaa | aaaaa |

| Shore hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com