Novel leaching separation method for nickel-cobalt alloy material containing molybdenum and vanadium

The technology of a nickel-cobalt alloy and a new method is applied in the field of leaching and separation of valuable metals in nickel-cobalt alloy materials, which can solve the problems of low comprehensive recovery rate, low recovery rate of molybdenum and vanadium, complicated process operation, etc., and achieve overall process coherence. , The effect of strong operability and process cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

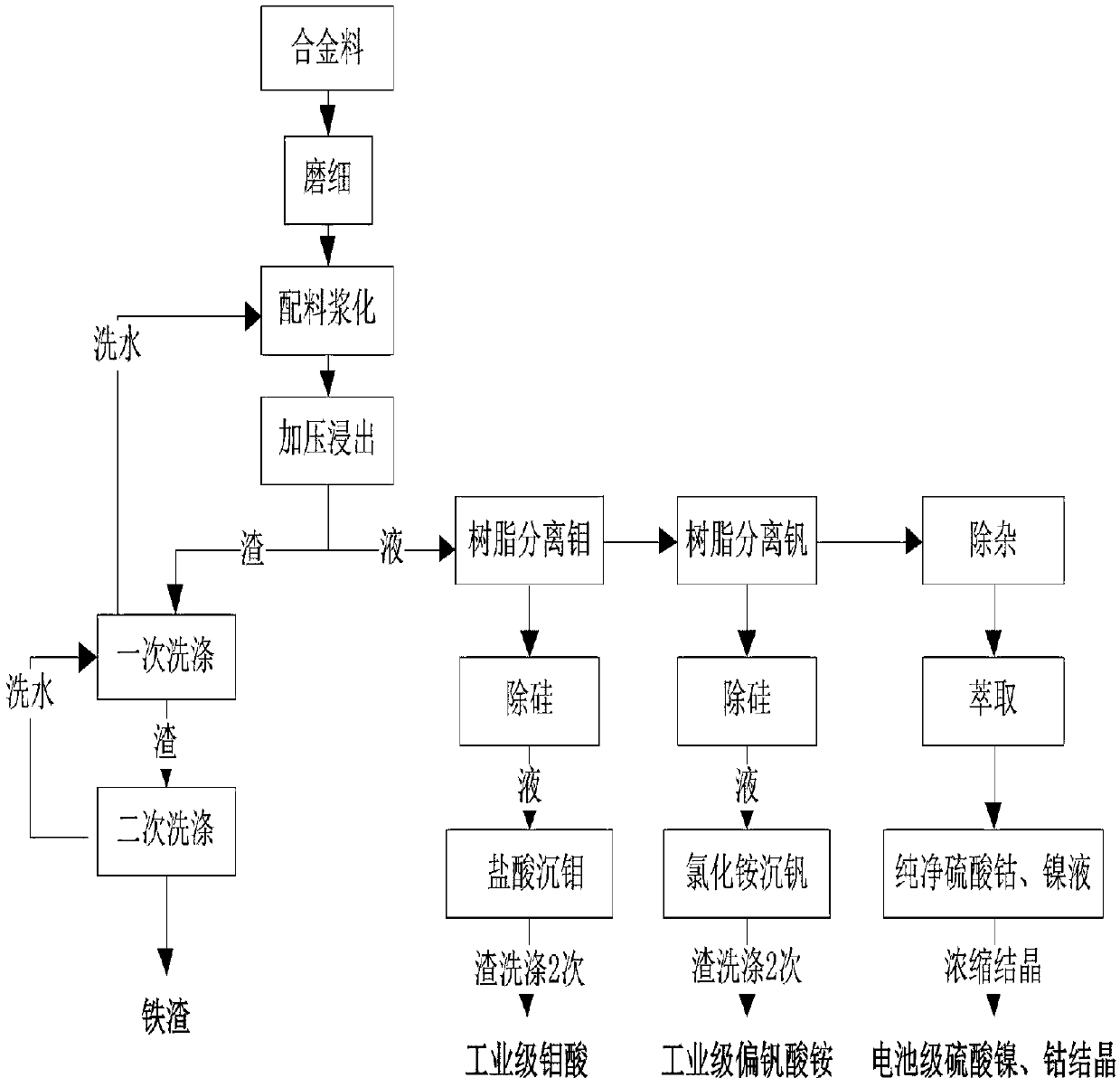

[0050] like figure 1 As shown, a number of other wastes containing molybdenum, vanadium, cobalt and nickel discharged from a chemical plant were taken, and the cobalt-nickel alloy material containing molybdenum and vanadium was obtained by mixing and reducing smelting in an electric furnace. The content of Co in the alloy material was detected to be 14.68%, and the content of Ni The content is 26.45%, the content of Mo is 19.56%, the content of Fe is 18.31%, and the content of V is 13.6%; The above-mentioned alloy material is carried out as follows:

[0051] (1) Grinding: the alloy material is ground and sieved to below 100 mesh, and then the alloy powder after grinding and sieving is processed as follows:

[0052] (2) Batching slurry reaction: Add water and sulfuric acid to the above alloy powder according to the liquid-solid ratio of 8:1 and the acid-material ratio of 1.8:1, mix them, and react at 70°C for 2 hours to obtain a slurry reaction After liquid.

[0053] (3) Pres...

Embodiment 2

[0074] like figure 1As shown, a number of waste catalysts containing molybdenum, vanadium, cobalt and nickel discharged from a chemical plant were taken, and the cobalt-nickel alloy material containing molybdenum and vanadium was obtained by mixing and reducing smelting in an electric furnace. After testing, the content of Co in the alloy material was 13.27%, and the content of Ni Content is 24.65%, the content of Mo is 21.86%, the content of Fe is 21.35%, the content of V is 12.86%; The above-mentioned alloy material is carried out as follows:

[0075] (1) Grinding: the alloy material is ground and sieved to below 100 mesh, and then the alloy powder after grinding and sieving is processed as follows:

[0076] (2) Batching slurry reaction: add water and sulfuric acid to the above alloy powder according to the liquid-solid ratio of 12:1 and the acid-material ratio of 2:1, mix them, and react at 70°C for 2 hours to obtain a slurry reaction After liquid.

[0077] (3) Pressurize...

Embodiment 3

[0098] like figure 1 As shown, some waste alloy materials containing molybdenum, vanadium, cobalt and nickel discharged from a chemical plant were taken, and the cobalt-nickel alloy materials containing molybdenum and vanadium were obtained by mixing and reducing smelting in an electric furnace. The content of Co in the alloy material was detected to be 14.67%, Ni The content of Mo is 23.65%, the content of Mo is 22.46%, the content of Fe is 25.51%, and the content of V is 13.12%; The above-mentioned alloy material is carried out as follows:

[0099] (1) Grinding: the alloy material is ground and sieved to below 100 mesh, and then the alloy powder after grinding and sieving is processed as follows:

[0100] (2) Batching slurry reaction: add water and sulfuric acid to the above alloy powder according to the liquid-solid ratio of 15:1 and the acid-material ratio of 2.5:1, mix them, and react at 70°C for 2 hours to obtain a slurry reaction After liquid.

[0101] (3) Pressurized...

PUM

| Property | Measurement | Unit |

|---|---|---|

| recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com