A high-precision lamination method of steel-concrete composite beam prefabricated concrete bridge deck and steel beam

A technology of prefabricated concrete and steel-concrete composite beams, which is applied to bridges, bridge construction, bridge parts, etc., can solve the problems of decreased mechanical properties and great difficulties brought about by the control of prefabricated precision and superposition precision of bridge decks, and achieves the goal of construction High efficiency, significant economic and social benefits, and shortened construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will be further described below in conjunction with the accompanying drawings.

[0044] The high-precision lamination method of steel-concrete composite girder prefabricated concrete bridge deck and steel girder according to the present invention comprises the following steps:

[0045] Step 1: Preparation of precast concrete bridge decks: Precast concrete bridge decks are prepared using prefabricated molds.

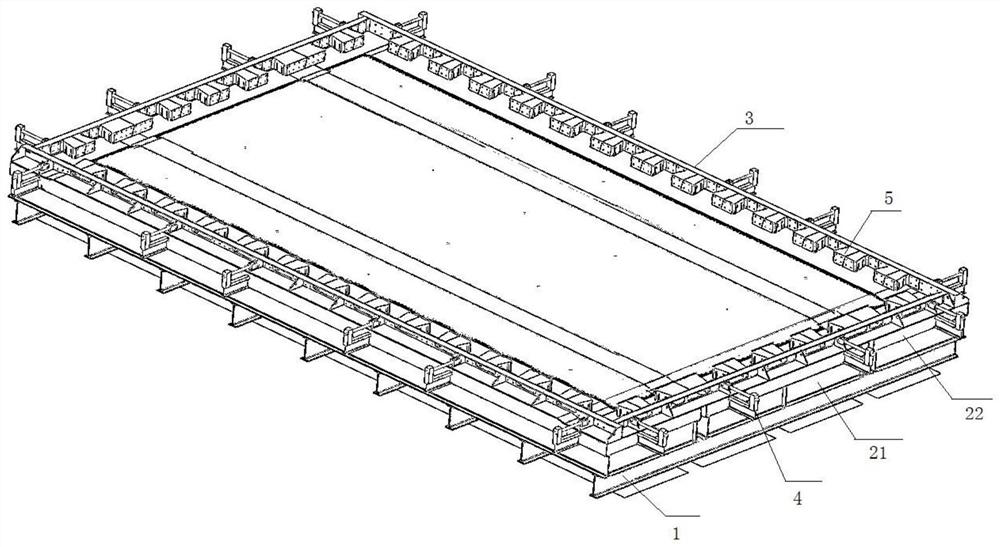

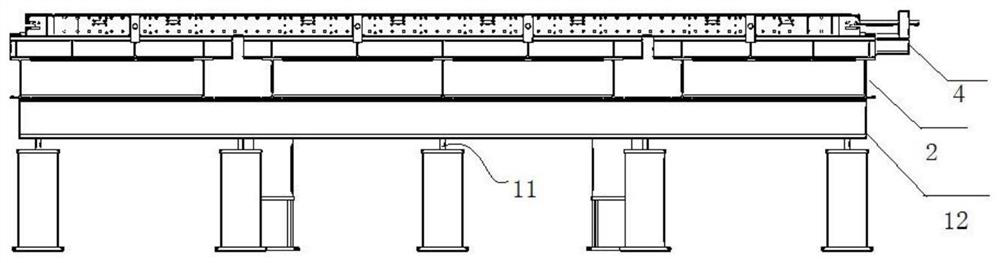

[0046] Such as figure 1 Shown, be the prefabricated mold of the preparation prefabricated concrete bridge deck of the present invention, as figure 1 and figure 2 As shown, it includes a base 1, a bottom mold 2 positioned on the upper layer of the base 1, a side mold 3 positioned around the bottom mold 2, a demoulding device 4 positioned outside the side mold, and a core mold 5 positioned inside the side mold.

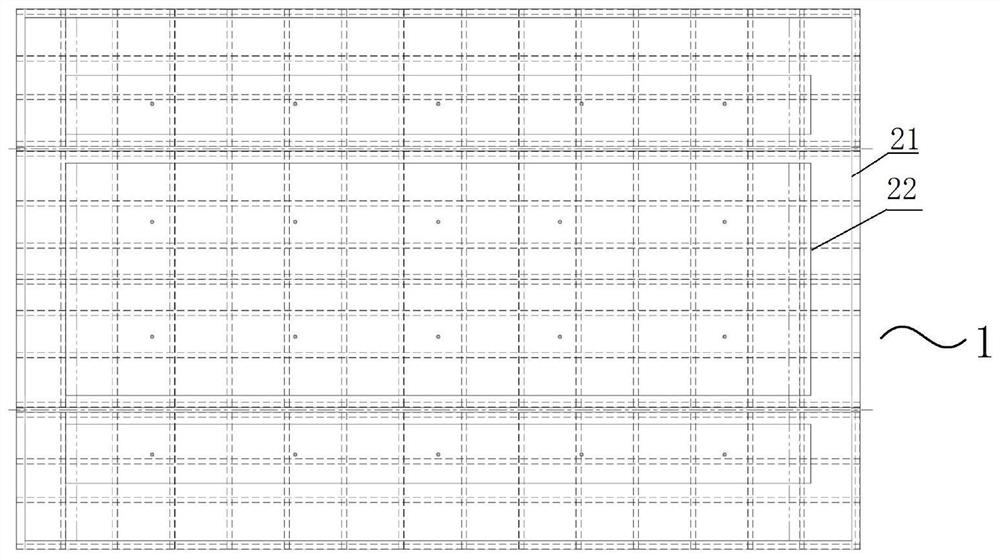

[0047] Such as image 3 and Figure 4As shown, the base 1 is composed of a number of longitudinal beams parallel to each other a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com