High-voltage enclosed bus online monitoring management system based on optical fiber

A closed bus, monitoring and management technology, applied in measuring devices, measuring heat, thermometers with physical/chemical changes, etc., can solve problems such as difficult to meet requirements, and achieve the effects of no electromagnetic interference, improved standards, and high monitoring accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

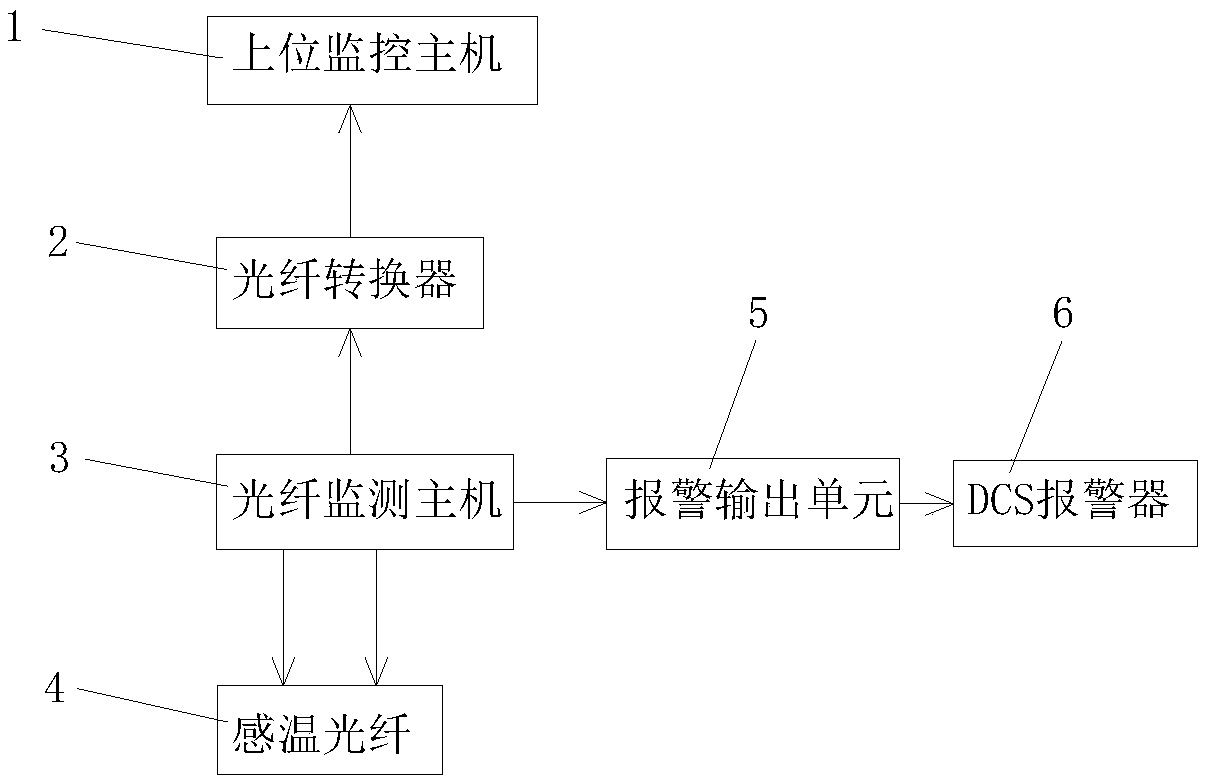

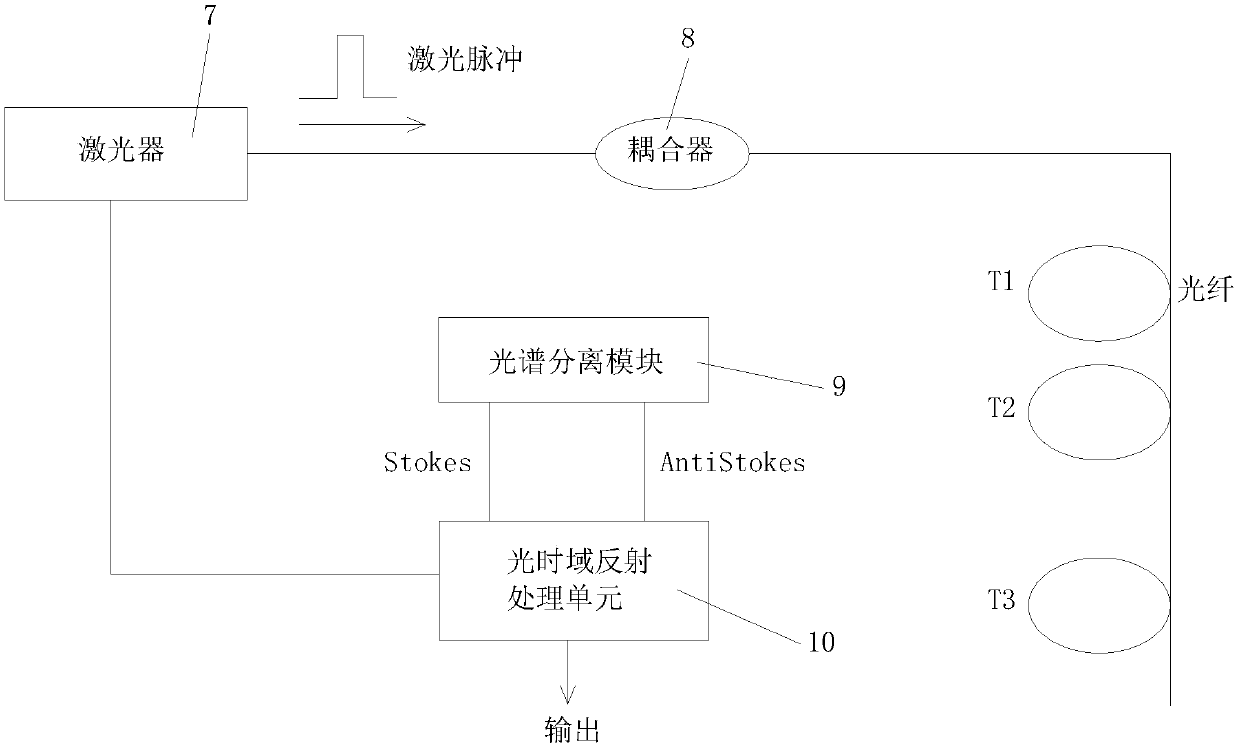

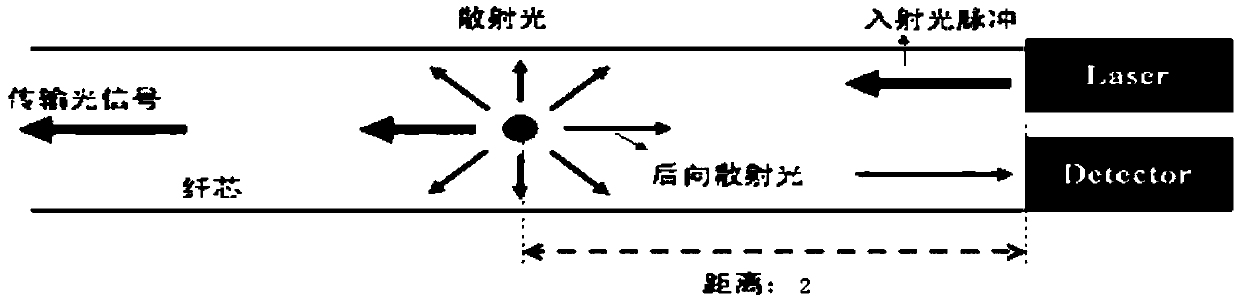

[0026] Such as Figure 1-4 As shown, a high-voltage closed bus online monitoring and management system based on optical fiber includes an upper monitoring host 1 for managing subordinate equipment and receiving analysis data; an optical fiber converter 2 connected to the upper monitoring host 1 for converting optical fiber signal; the optical fiber monitoring host 3 connected to the optical fiber converter 2 is used to be responsible for signal acquisition, signal processing, data analysis, over-temperature alarm, temperature rise rate alarm, network transmission, etc. of the entire system; and the optical fiber monitoring host The temperature-sensitive optical fiber 4 connected to 3 is used to connect the high-voltage closed busbar and serves as a carrier for signal transmission; the alarm output unit 5 connected to the optical fiber monitoring host 3 is used for the transmission of alarm information; it is connected to the alarm output unit 5 The DCS alarm 6 is used for DCS ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com