TSV array temperature optimization method based on an orthogonal test

A technology of orthogonal test and optimization method, applied in the field of microelectronics, can solve the problems of low accuracy, large workload, poor general applicability, etc., to improve efficiency and accuracy, reduce required time, avoid comprehensive testing and The effect of random error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Embodiments and effects of the present invention will be described in further detail below with reference to the accompanying drawings.

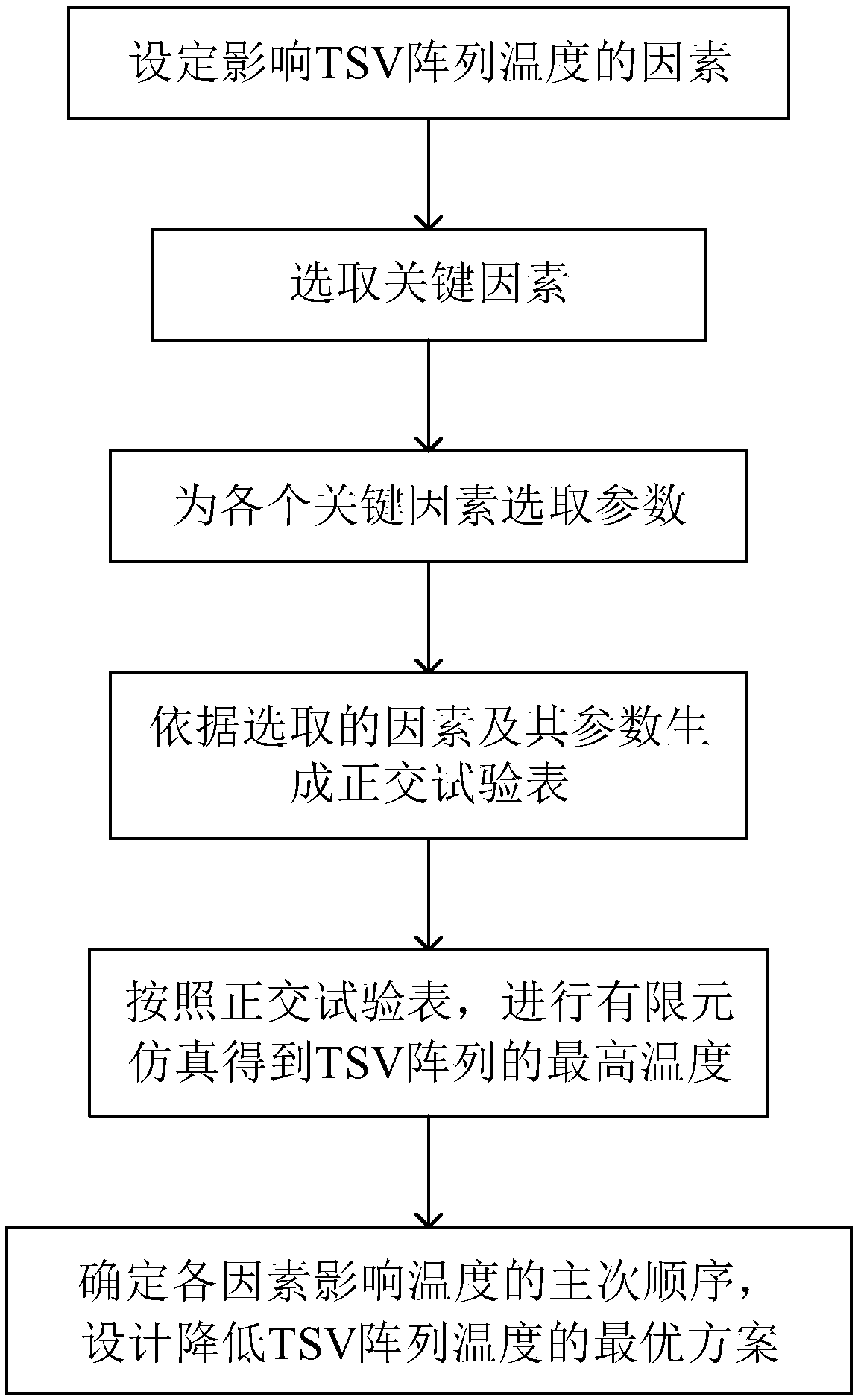

[0024] refer to figure 1 , the present invention is based on the orthogonal experiment TSV array temperature optimization method, the implementation steps are as follows:

[0025] Step 1. Set the factors that affect the temperature of the TSV array.

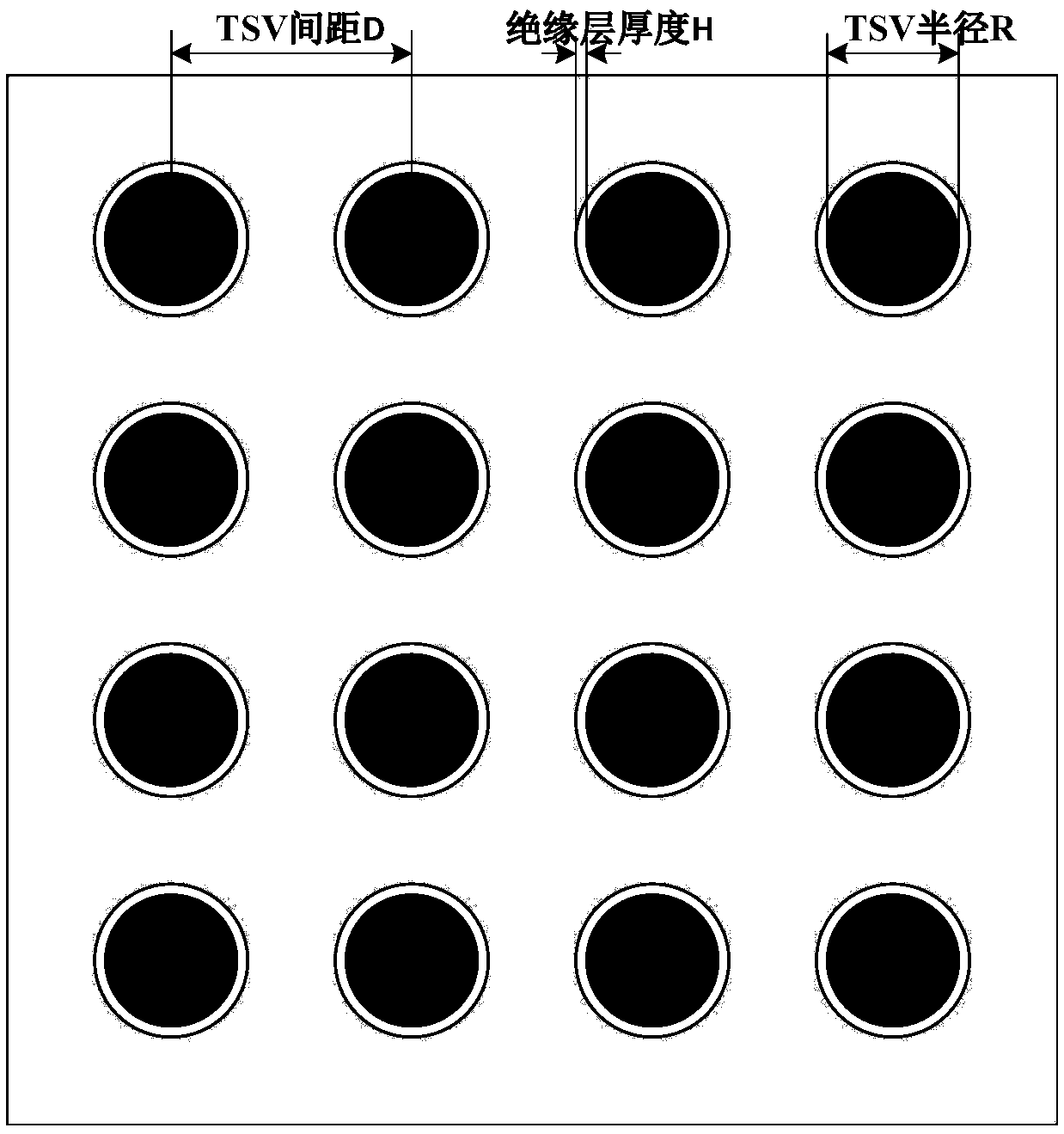

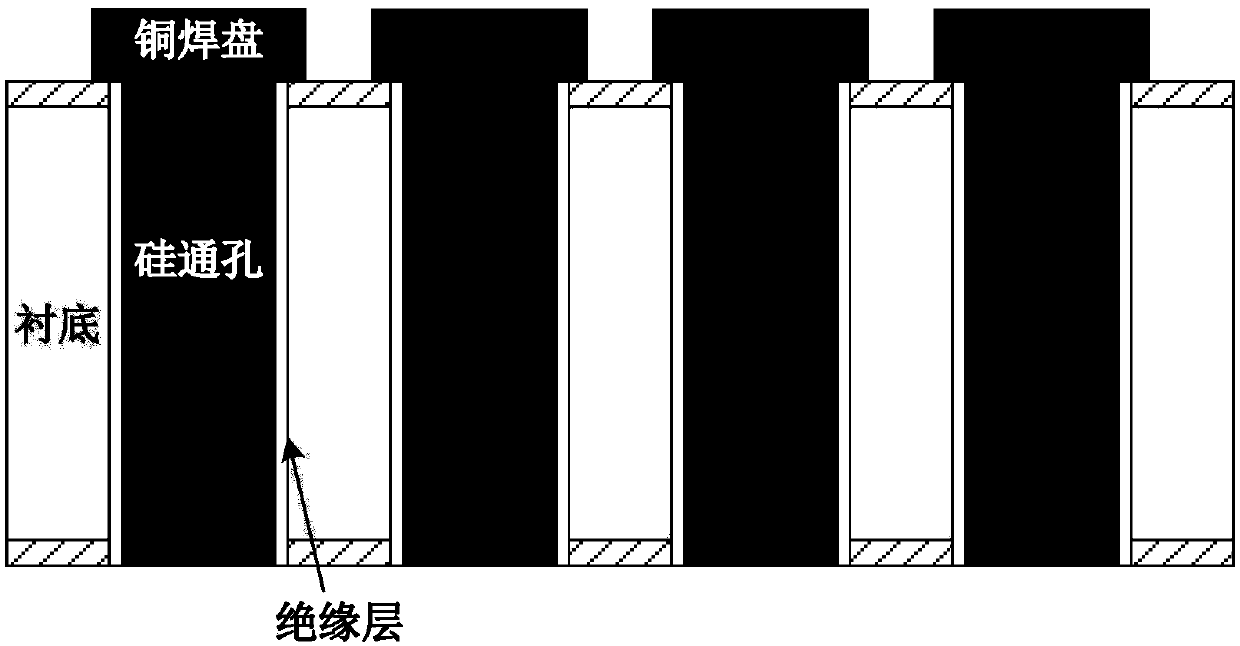

[0026] The set factors include: hole category C, radius R, spacing D, filling material M tsv , arrangement S, insulating layer thickness H and insulating layer material M iso .

[0027] Step 2. Select the key factors affecting the temperature of the TSV array.

[0028] Select at least three factors from the factors that affect the temperature of the TSV array as the key factors. The number of key factors selected in this example is four, namely, the radius R of the TSV, the spacing D of the TSV, the thickness H of the insulating layer, and the material of the insulating layer. m is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Radius | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com