High-altitude saw

A high-altitude saw and saw blade technology, applied in cutting tools, cutting equipment, gardening, etc., can solve the problems of reduced work efficiency and single function, and achieve the effect of reducing direct contact, convenient height, and reducing the probability of corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

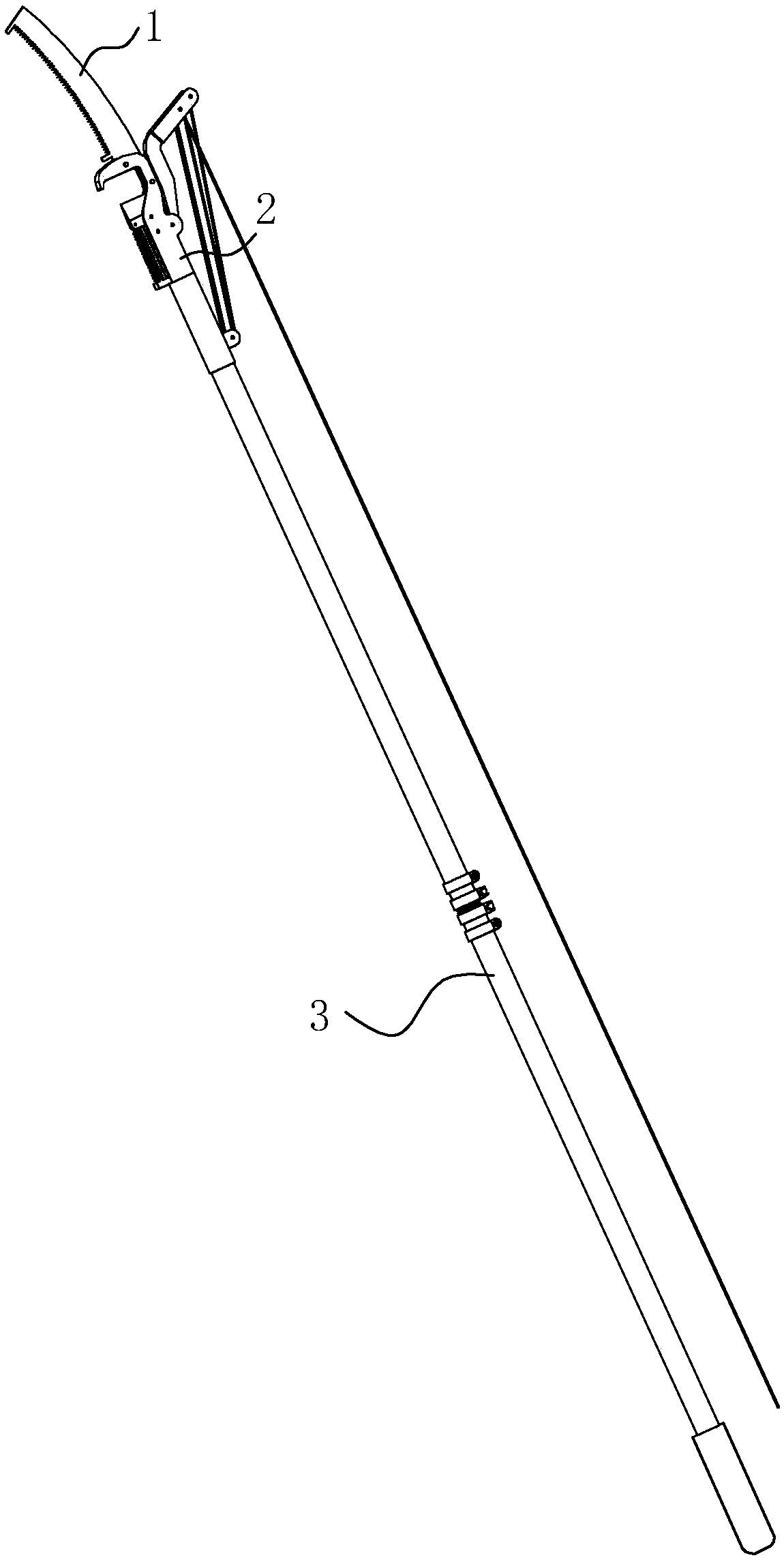

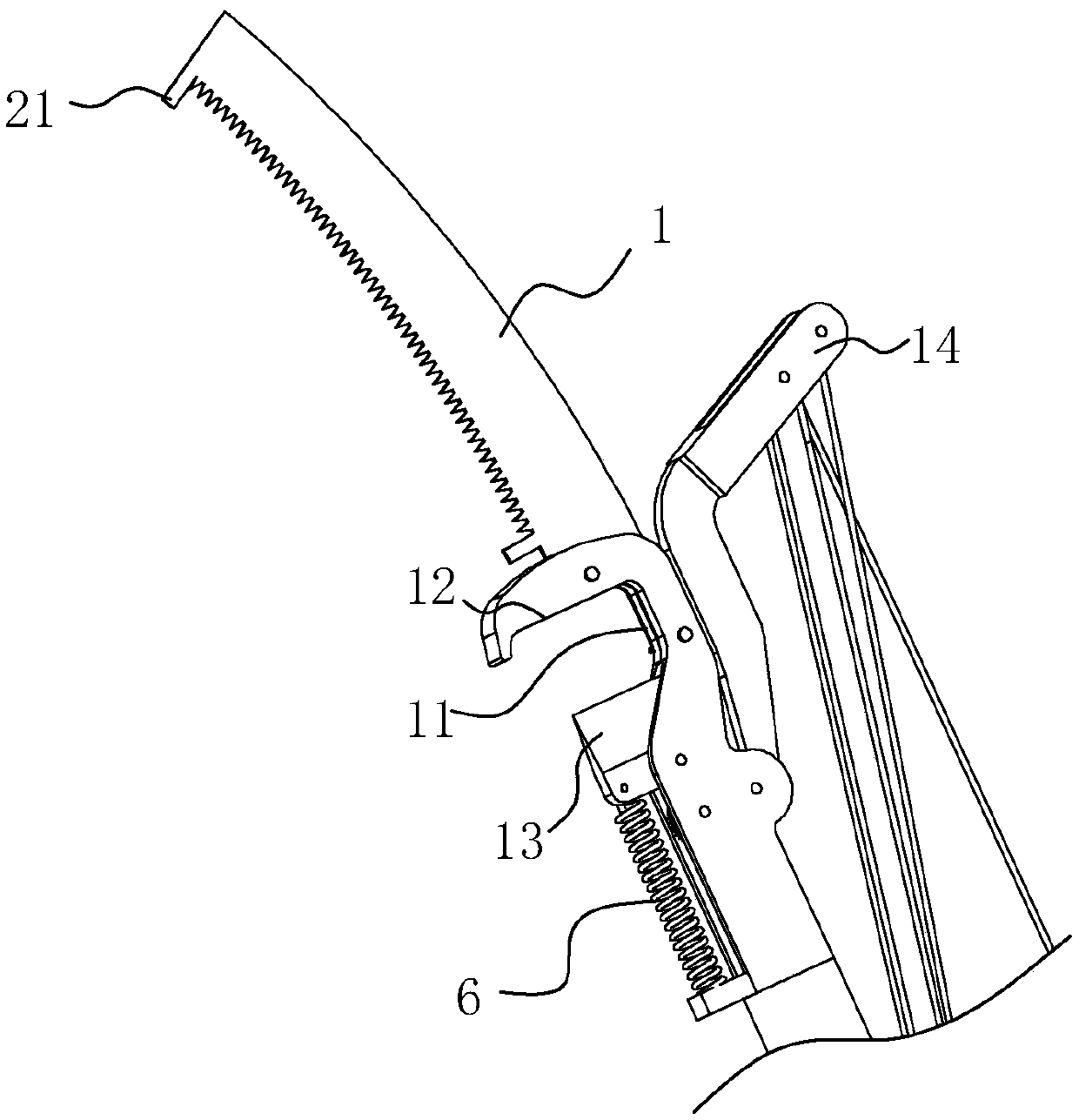

[0048] A high-altitude saw combined with an attached figure 1 And attached figure 2 , comprising a base 1 and a saw blade 2 fixed on the base 1, where the saw blade 2 is arc-shaped, and the front and rear ends of the saw blade 2 are provided with protrusions 21 facing the sawtooth direction, so that in the process of sawing, The problem of stripping the saw can be avoided. At the same time, one end of the base 1 away from the saw blade 2 is fixed to the straight rod 3 .

[0049] In addition, as attached figure 2 As shown, there is a notch 11 on the side of the base 1 , the upper edge of the notch 11 has a cutout 12 , and the base 1 is hinged with a cutout 2 13 . Clip two 13 is located below clip one 12 . When the first piece 12 rotates with the hinge point as the axis, the first piece 12 and the second piece 13 will be closed, so that the object between the first piece 12 and the second piece 13 can be cut off.

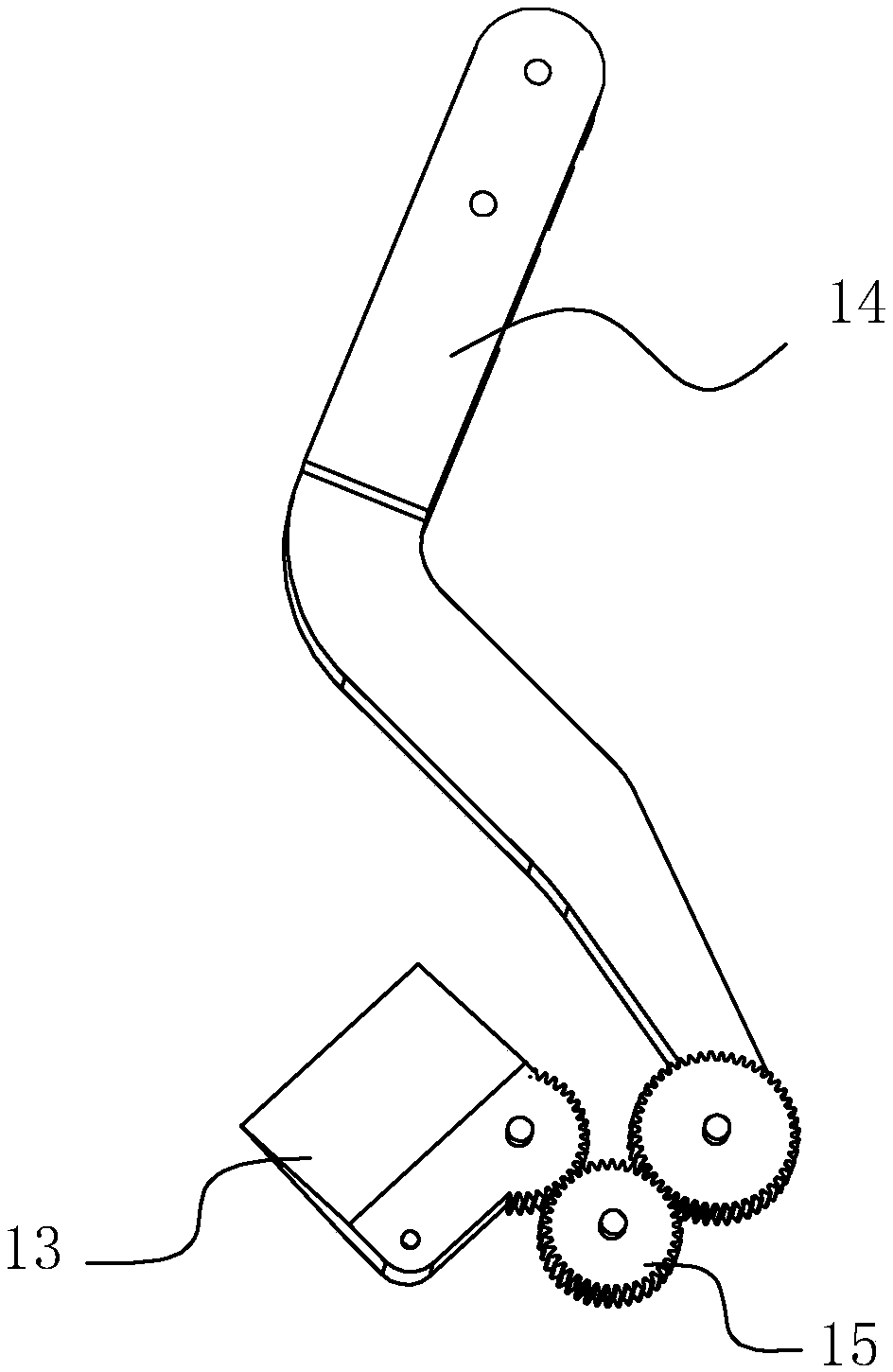

[0050] Secondly, as attached image 3 As shown, here the...

Embodiment 2

[0054] A high-altitude saw, as attached Figure 6 As shown, the only difference from the first embodiment is that the second clip 13 is hinged to the side of the base 1 , and the plectrum 14 is also hinged to the side of the base 1 . Simultaneously, the opposite end of the second piece 13 is hinged with the plectrum 14, so that when the plectrum 14 rotates, it can also drive the second piece 13 and the first piece 12 to cut.

[0055] Moreover, the plectrum 14 here is connected with the position near the front end of the base 1 by a return spring 6, so that after cutting, the cutting piece 2 13 can be restored.

Embodiment 3

[0057] A high-altitude saw, as attached Figure 7 As shown, on the basis of embodiment one or embodiment two, the lower end of the straight rod has a grip pad 7 of thermoplastic elastomer, and its production steps include:

[0058] Step 1. Weigh 22Kg SBS and 12Kg SEBS into the mixer, add 45Kg white oil, and preheat the materials in the mixer. The preheating temperature is 70-80°C, and the stirring blade in the mixer Stir and mix the materials at a speed of 60rpm;

[0059] Step 2. After the white oil is completely absorbed by the material, add 10Kg PP, 4Kg maleic anhydride grafting agent, 4Kg POE elastomer, 2g erucic acid, 3g silicone, 12Kg coral powder, TAF 3Kg, fatty acid methyl ester polyoxyethylene ether 6Kg, lithium iodide 8Kg, 2-(2'-hydroxyl-3', 5'-di-tert-phenyl)-5-chlorinated benzotriazole 3Kg and antioxidant 7Kg, after stirring evenly, heat the temperature to 80-90°C and keep it for 1h to obtain the mixture;

[0060] Step 3: Add the mixture in step 2 to an extruder ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com