Automatic cooking machine and cooking method thereof

A technology of automatic cooking and cooking device, which is applied to cooking utensils, furniture or equipment in the service industry, household appliances, etc., can solve the problems of large space occupation, long waiting time, low cooking efficiency, etc., and achieves improved production efficiency and compact structure. , the effect of improving cooking efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

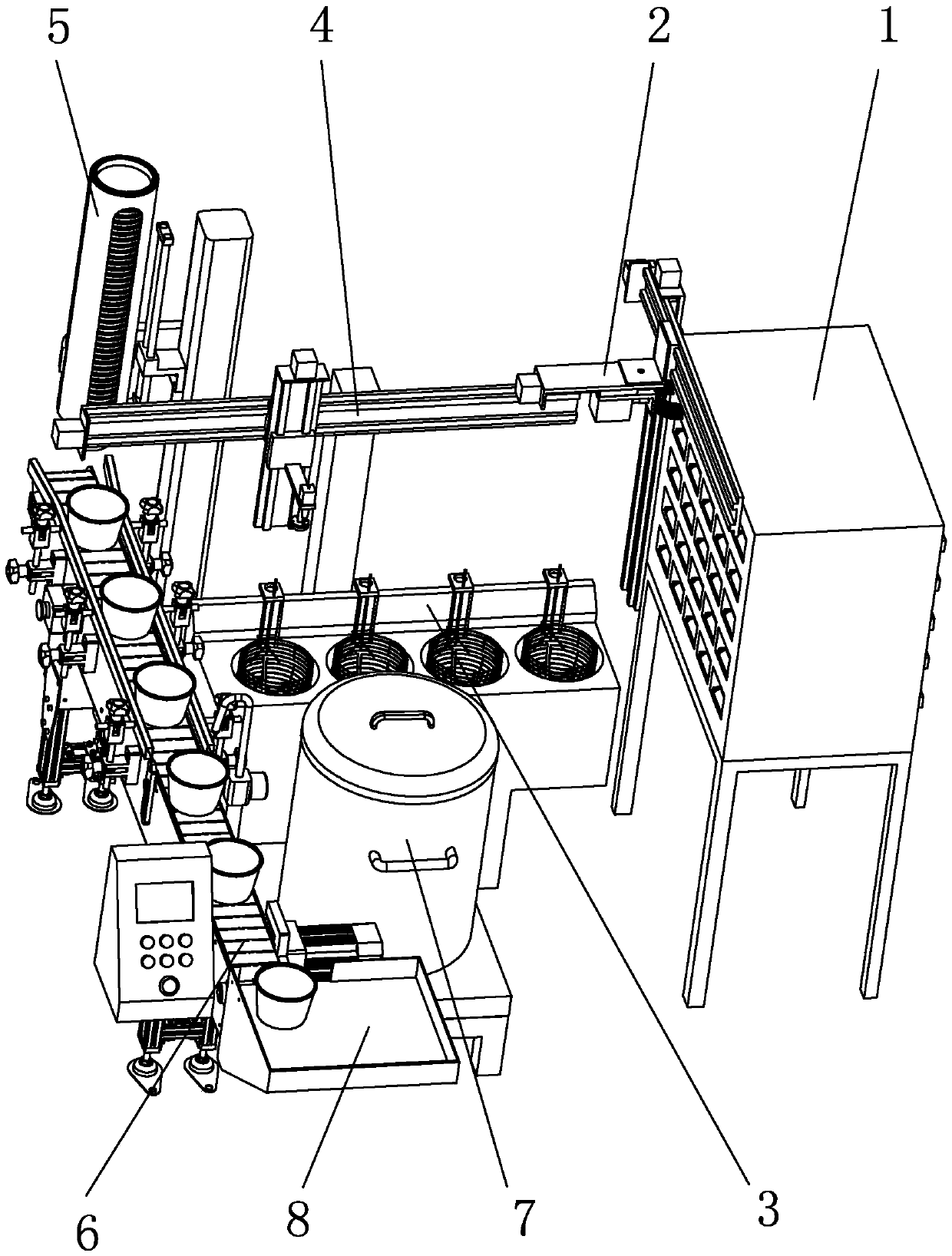

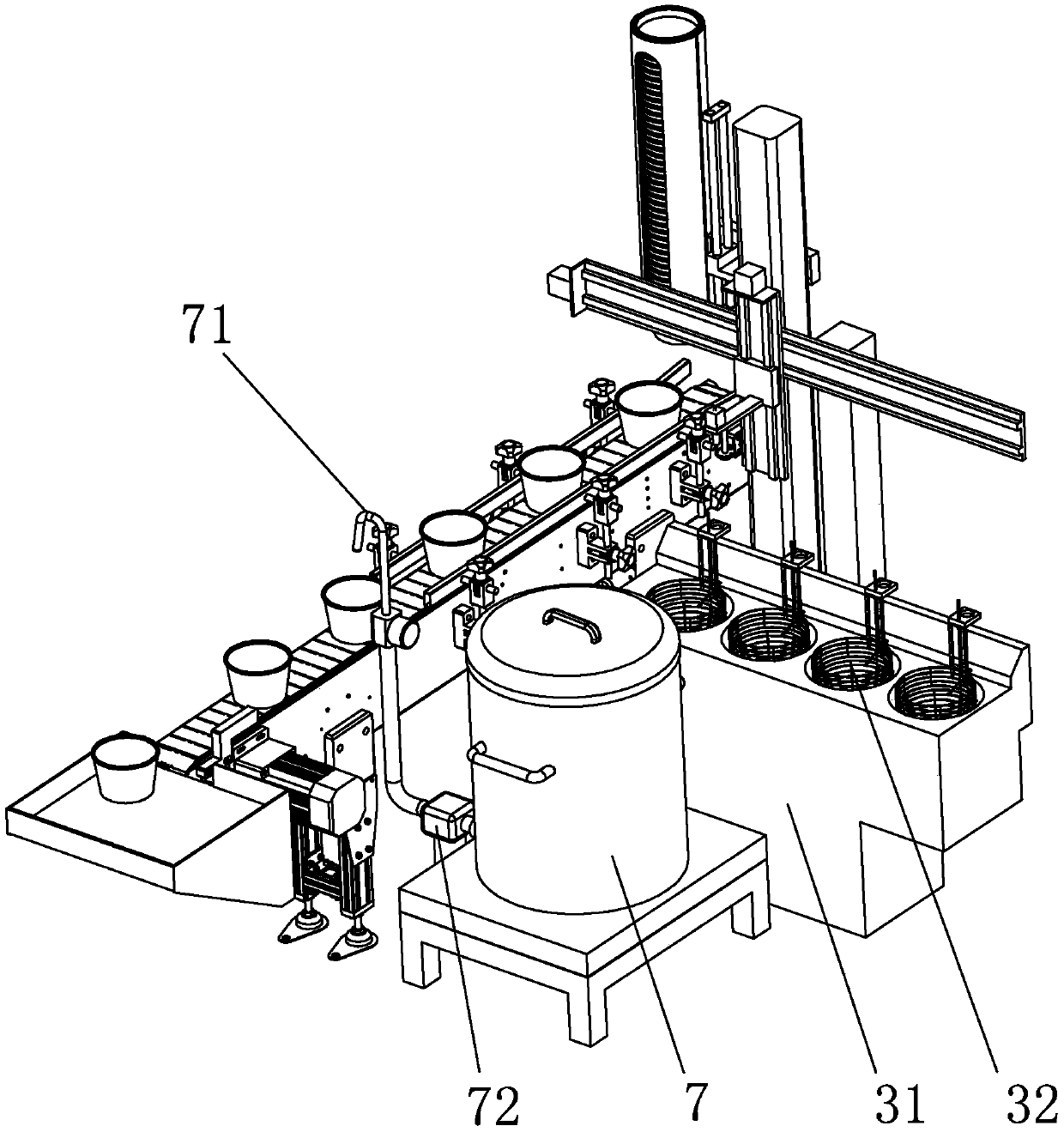

[0034] together with reference Figure 1 to Figure 5 , is a preferred embodiment, an automatic cooking machine, including the following components;

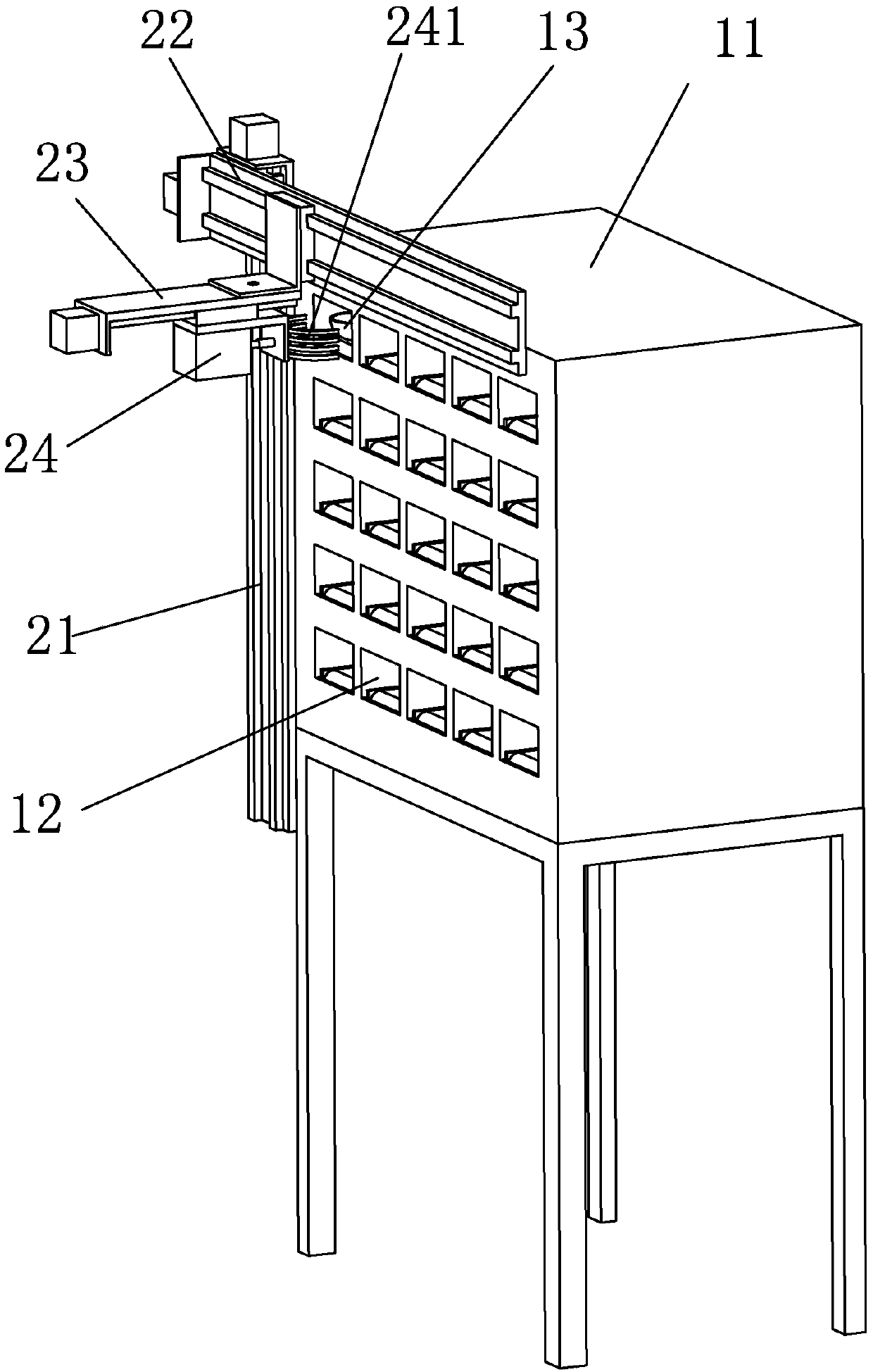

[0035] The material storage device 1 comprises a casing 11 and a material storage chamber 12 arranged inside the casing 11, the material storage chamber 12 is used to place a material bowl 13, and the material bowl 13 contains food materials such as uncooked noodles or vermicelli. The chamber 12 is a square passage running through the middle of the box body 11, which is convenient for the operator to discharge from one side and the machine to take out the material from the other side;

[0036] The first feeding assembly 2 is used to put the food material in the storage device 1 into the cooking device 3, and includes a first guide mechanism and a mechanical claw 24 installed on the first guide mechanism, and the first guide mechanism is XYZ The three-axis guide rail includes a Z-axis guide rail 21 fixedly installed on the box bo...

Embodiment 2

[0064] This embodiment is another preferred embodiment of the present invention, including a material storage device 1, a first feeding assembly 2, a cooking device 3, a second feeding assembly 4, and a third feeding assembly 5. This embodiment and The difference of embodiment 1 is:

[0065] A spoon handle is provided above the spoon body 321 of the cooking spoon 32, and a clamping mechanism is provided on the slider. movement of the cooking spoon;

[0066] The fetching claw 241 of the mechanical claw 24 includes two clips, and the clips pass through the top and bottom of the clamping bowl 13, so that the flipping and unloading of the bowl 13 can also be realized;

[0067] The X-axis guide rail of the first feeding assembly 2 is replaced by a telescopic plate structure. The telescopic plate includes an upper plate and a lower plate. The upper plate is installed on the Y-axis guide rail. The lower plate can move along the lower plate. The mechanical claw 24 is fixed on the low...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com