Quartz sand-modified sulfydryl-loaded material for removing mercury from sewage and preparation method thereof

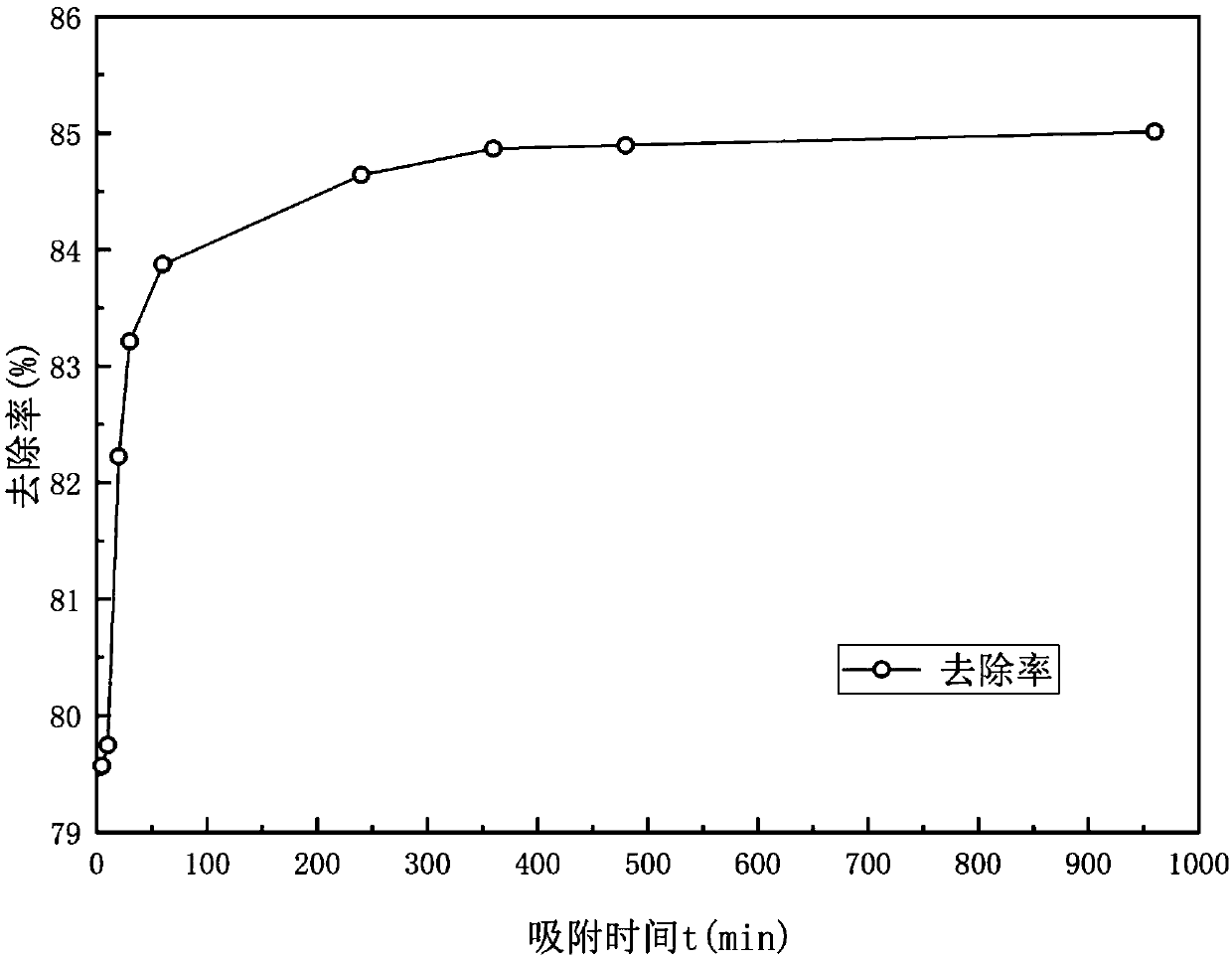

A quartz sand and sulfhydryl technology, applied in water/sewage treatment, chemical instruments and methods, adsorbed water/sewage treatment, etc., can solve the problems of excessive mercury content, inconvenient management, complex graphene derivative method technology, etc., and achieve saturation. The effect of improved adsorption capacity and convenient application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] A modified quartz sand-loaded mercapto material for mercury removal in sewage, which is composed of quartz sand and functional group mercapto compound. The quartz sand is first modified with hydrochloric acid and ethanol solution, and then treated with thioglycolic acid through cosolvent acetic anhydride and sulfuric acid. react, and load the functional group mercapto on the surface of the quartz sand.

[0022] Its preparation process is as follows:

[0023] a. Put the quartz sand in a 30-mesh stainless steel sieve to sieve out the 0.75-0.83mm quartz sand filter material, then boil it with pure water for 60 minutes, then wash it repeatedly with pure water until it is no longer turbid, and finally dry it in a vacuum at 105°C Dry in the oven for 12 hours, and take out the quartz sand after cooling to constant weight;

[0024] b. Soak the quartz sand obtained in step a with 1mol / L hydrochloric acid for 24 hours, then put it into an ethanol solution and stir it magneticall...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com