High-efficiency uranium adsorbent prepared from bentonite-grafted graphene oxide and preparation method thereof

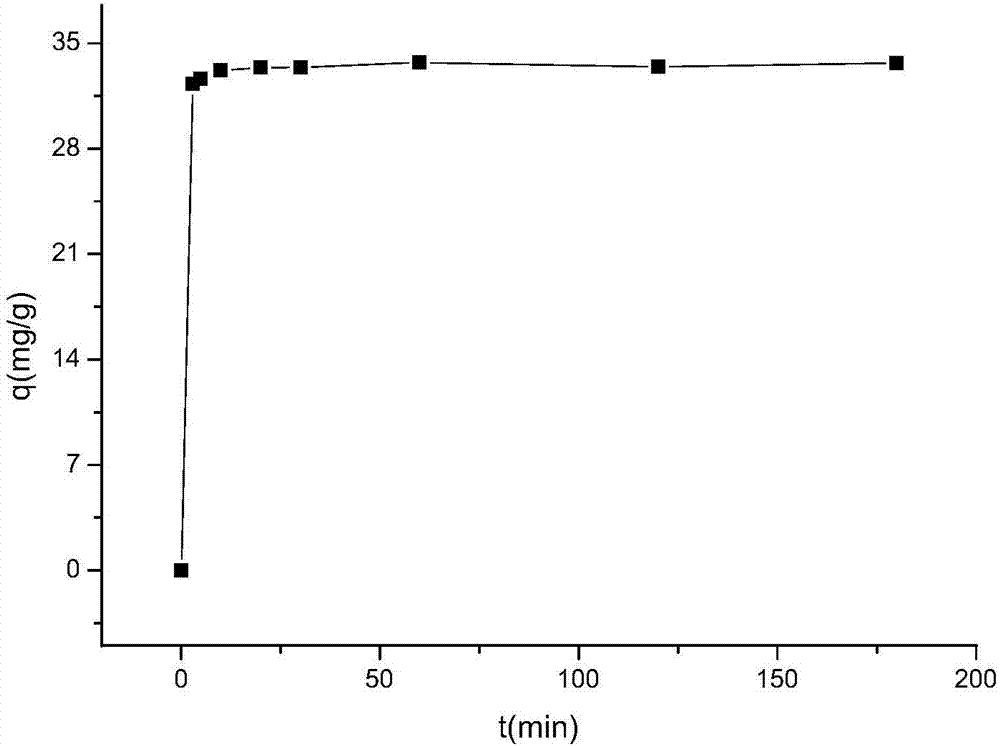

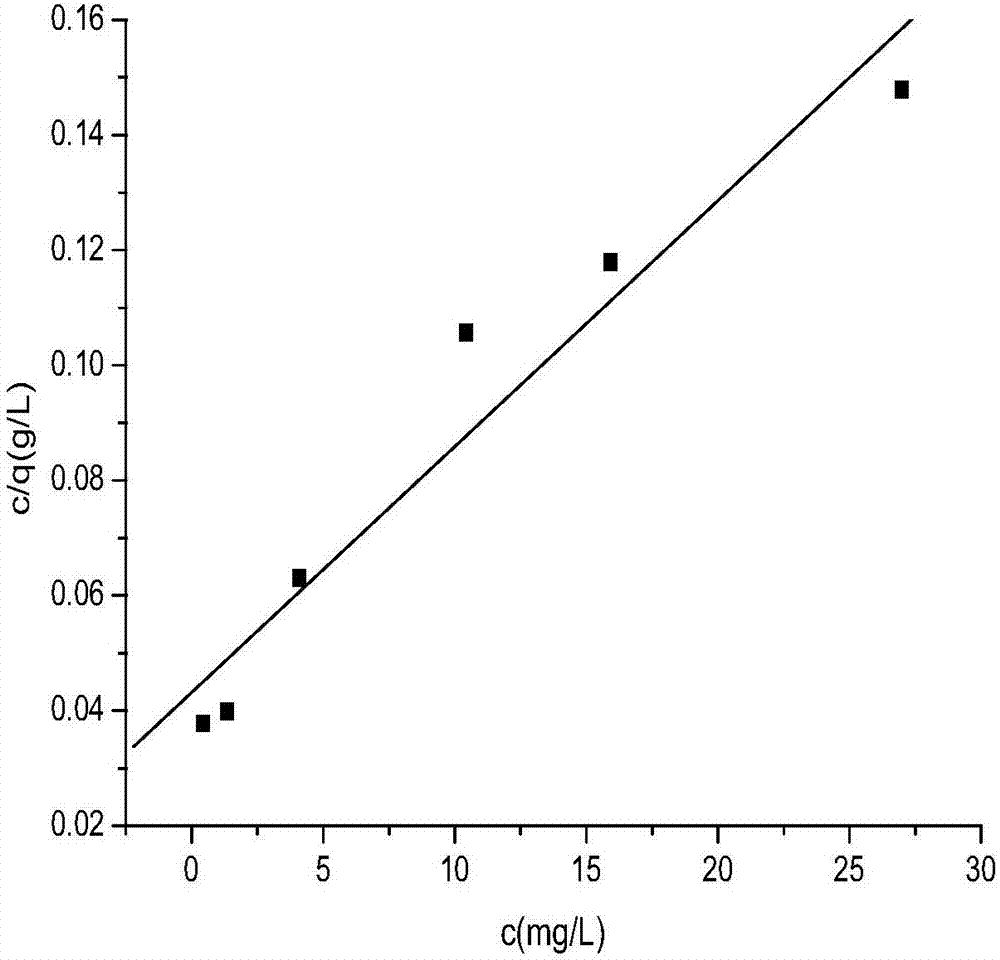

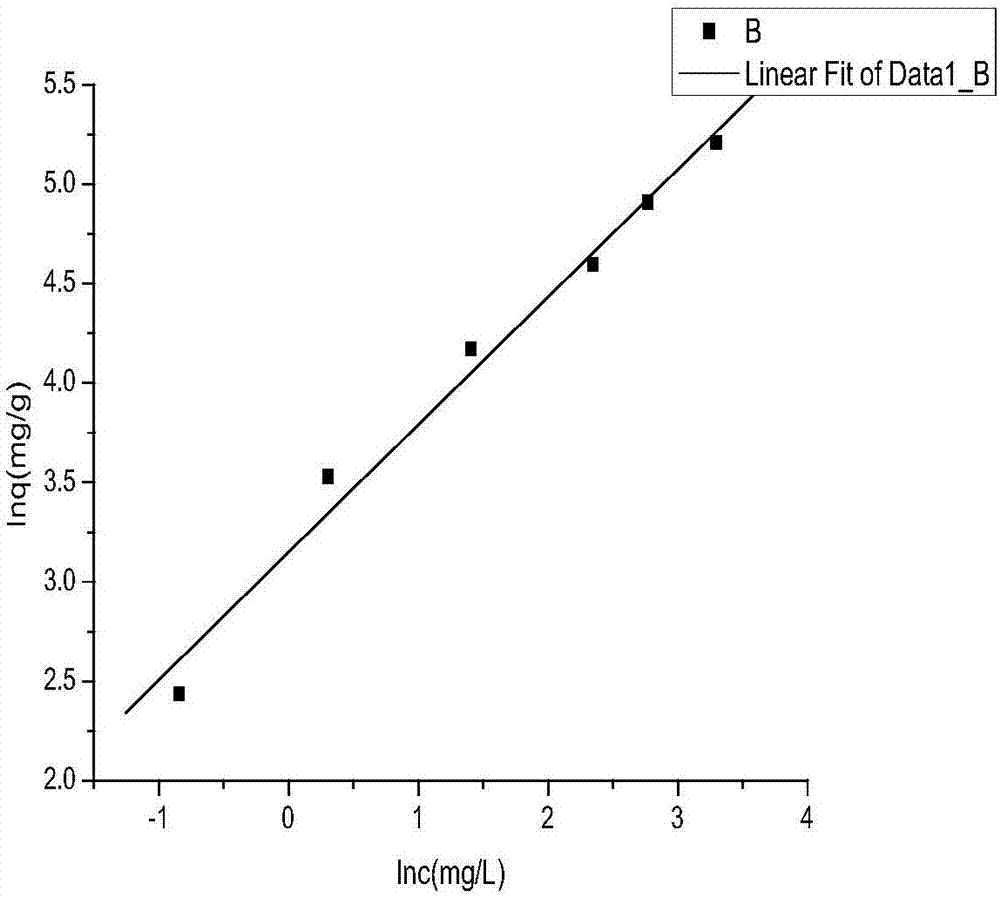

A technology of bentonite and graphene, applied in chemical instruments and methods, adsorption water/sewage treatment, other chemical processes, etc., can solve the problems of low adsorption rate and poor adsorption effect, achieve fast adsorption rate, simple preparation method, The effect of high saturated adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] A kind of high-efficiency uranium adsorbent of bentonite grafted graphene oxide, its preparation method comprises the following steps:

[0038] (1) ultrasonically disperse 0.4g graphene oxide in 200mL deionized water to obtain a graphene oxide suspension;

[0039] (2) Add 14g of bentonite to 100mL of deionized water and stir to obtain bentonite suspension;

[0040] (3) Mix the graphene oxide suspension and the bentonite suspension, stir evenly, then add 17mL of sodium hydroxide solution with a mass concentration of 40%, stir and mix, then drop into 17mL epichlorohydrin, mix well, and heat to 65°C, finally add 17mL of 1% ammonium persulfate solution and 4mL of 1% sodium bisulfite aqueous solution successively, after constant temperature stirring and polymerization for 3h, stop stirring, filter with suction, wash with acetone and distilled water until neutral, and cool naturally to At room temperature, vacuum-dry at 80°C for 6.5 hours, and grind into powder; wherein, the...

Embodiment 2

[0042] A kind of high-efficiency uranium adsorbent of bentonite grafted graphene oxide, its preparation method comprises the following steps:

[0043] (1) ultrasonically disperse 0.8g graphene oxide in 200mL deionized water to obtain a graphene oxide suspension;

[0044] (2) Add 16g of bentonite to 100mL of deionized water and stir to obtain bentonite suspension;

[0045] (3) Mix the graphene oxide suspension and the bentonite suspension, stir evenly, then add 22mL of sodium hydroxide solution with a mass concentration of 40%, stir and mix, then drop into 22mL epichlorohydrin, mix well, and heat to 75°C, finally add 22mL of 1% ammonium persulfate solution and 6mL of 1% sodium bisulfite aqueous solution successively, after constant temperature stirring and polymerization for 4h, stop stirring, filter with suction, wash with acetone and distilled water until neutral, and naturally cool to room temperature , vacuum-dried at 90°C for 5.5 hours, and ground into powder; wherein, th...

Embodiment 3

[0047] A kind of high-efficiency uranium adsorbent of bentonite grafted graphene oxide, its preparation method comprises the following steps:

[0048] (1) ultrasonically disperse 0.5g graphene oxide in 200mL deionized water to obtain a graphene oxide suspension;

[0049] (2) Add 15g of bentonite to 100mL of deionized water and stir to obtain bentonite suspension;

[0050] (3) Mix the graphene oxide suspension and the bentonite suspension, stir evenly, then add 20mL of sodium hydroxide solution with a mass concentration of 40%, stir and mix, then drop into 20mL epichlorohydrin, mix well, and heat to 70°C, finally add 19mL of 1% ammonium persulfate solution and 4.4mL of 1% sodium bisulfite aqueous solution in sequence, after constant temperature stirring and polymerization for 3 hours, stop stirring, filter with suction, wash with acetone and distilled water until neutral, and cool naturally to room temperature, vacuum-dried at 80°C for 6 hours, and ground into powder; wherein, t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com