Device and method for evaluating welding process performance of gas-shielded welding wire

A technology of welding process and evaluation device, which is applied in the field of welding process performance evaluation, and can solve the problems of incomplete performance evaluation of gas shielded welding wire

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

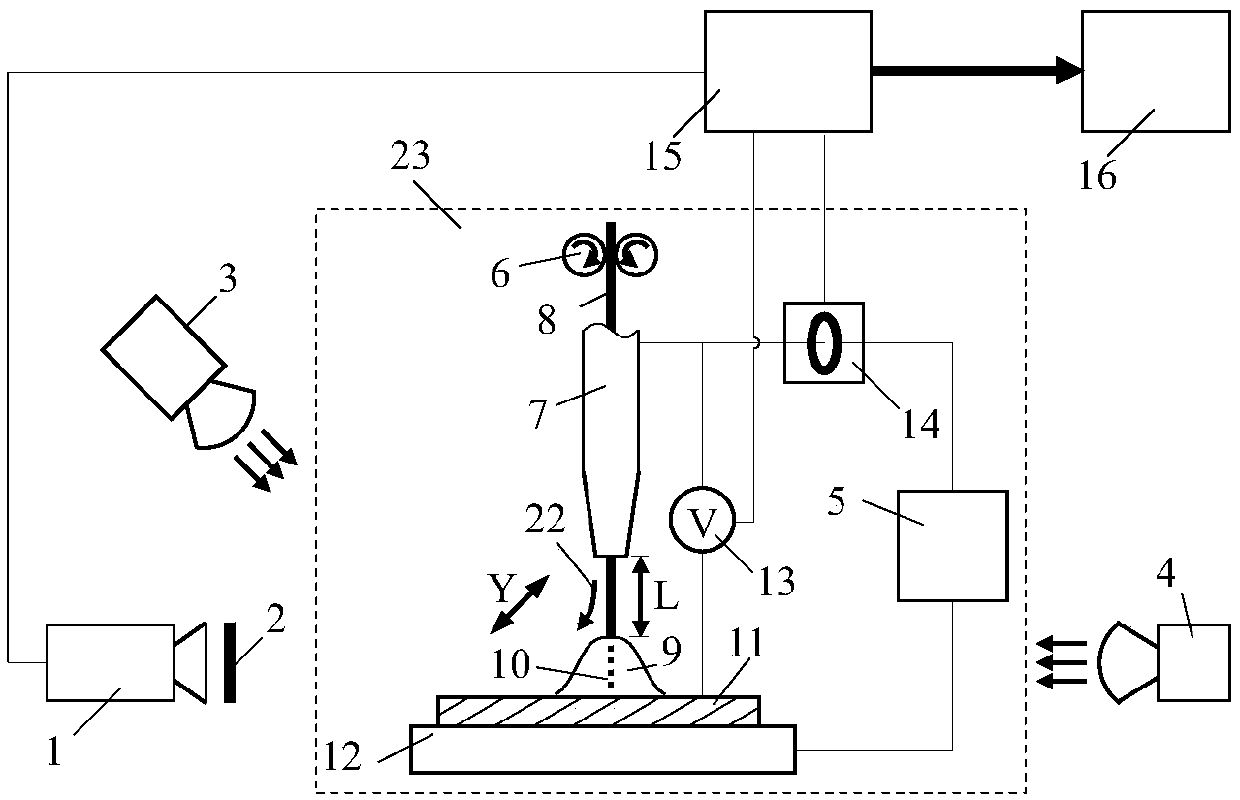

Method used

Image

Examples

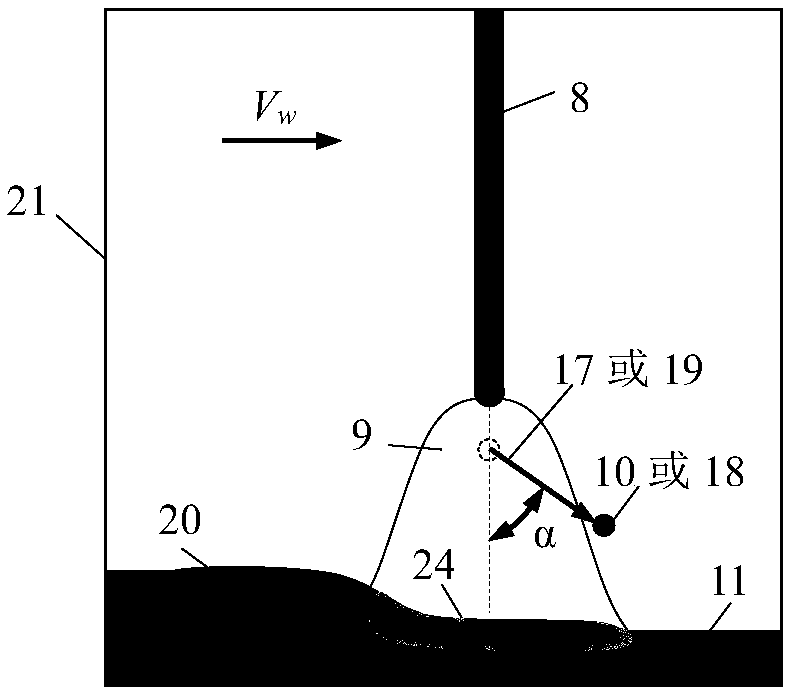

Embodiment 1

[0054] Such as Figure 7 Shown is an example of the evaluation of the welding process performance of the solid gas shielded welding wire 8 . The test conditions include: using a digital CCD high-speed camera 1 and auxiliary light source 2 4 to align the ends of the solid gas shielded welding wire 8 from both sides of the solid gas shielded welding wire 8; the auxiliary light source 2 4 has an illuminance of 4×10 5 Lux xenon lamp light source, high-speed camera 1 with aperture value F of 1 / 8, exposure time of 10μs, resolution of 256×256, and frequency of 7kHz; supporting optical filter system 2 includes a UV mirror, and a transmittance of 50% light reduction film, a filter with a center wavelength of 1100nm; the sampling frequency of the signal synchronous recorder 15 is 40kHz; the welding workpiece is low carbon steel with a thickness of 20mm; the average welding current is 300A, and the average arc voltage is 32.5V , welding speed V w 30cm / min, the length L of the welding w...

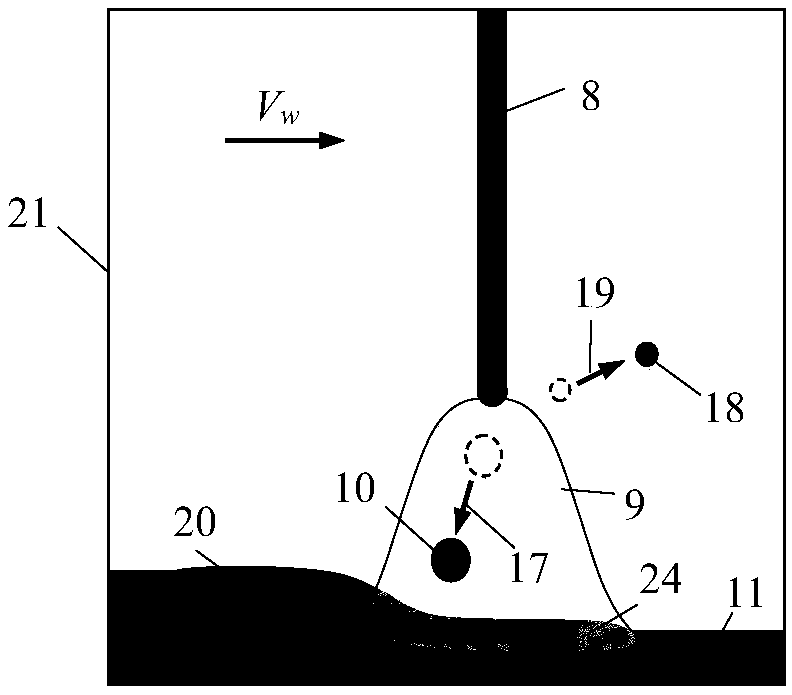

Embodiment 2

[0057] Such as Figure 8 Shown is an example of the evaluation of the welding process performance of the flux cored gas shielded welding wire 8. The test conditions include: using a digital CCD high-speed camera 1 and an auxiliary light source-3 to align the end of the flux-cored gas-shielded welding wire 8 from the same side of the flux-cored gas-shielded welding wire 8; the auxiliary light source-3 is a laser with a power of 30w Light source, the high-speed camera 1 has an aperture value F of 1 / 16, an exposure time of 25ms, a resolution of 512×512, and a frequency of 8kHz; the supporting optical filter system 2 includes a UV mirror and a UV mirror with a transmittance of 50%. A light-reducing film, a filter mirror with a center wavelength of 808nm; the sampling frequency of the signal synchronous recorder 15 is 40kHz; the welding workpiece is low carbon steel with a thickness of 20mm; the average welding current is 260A, the average arc voltage is 30V, and the welding speed ...

Embodiment 3

[0060] Such as Figure 9 Shown is an example of gas explosion splash detection, and the test conditions are the same as in Example 1. in, Figure 9 In (a), a droplet is formed at the end of the welding wire, and the droplet grows up with time, and the metallurgical reaction inside it produces a large amount of gas, which makes the droplet expand like a balloon inflated, see Figure 9 (b) and 9(c). When the surface tension of the outer surface of the droplet cannot suppress the internal gas pressure, the droplet explodes and forms a gas explosion splash, such as Figure 9 (d) and 9(e). The occurrence of gas explosion splash like this reflects that the alloy composition of the gas shielded welding wire is easy to generate gas, and there are many low melting point chemical elements, which is not conducive to the stability of the welding process of the 8 major specifications of the gas shielded welding wire.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com