Semi-solid food nourishment port pipe

A technology for semi-solid and nutritional products, which is applied in the field of semi-solid food and nutritional product mouth tubes, which can solve problems such as leakage, ineffective effects, and deterioration of contents, and achieve the effect of simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

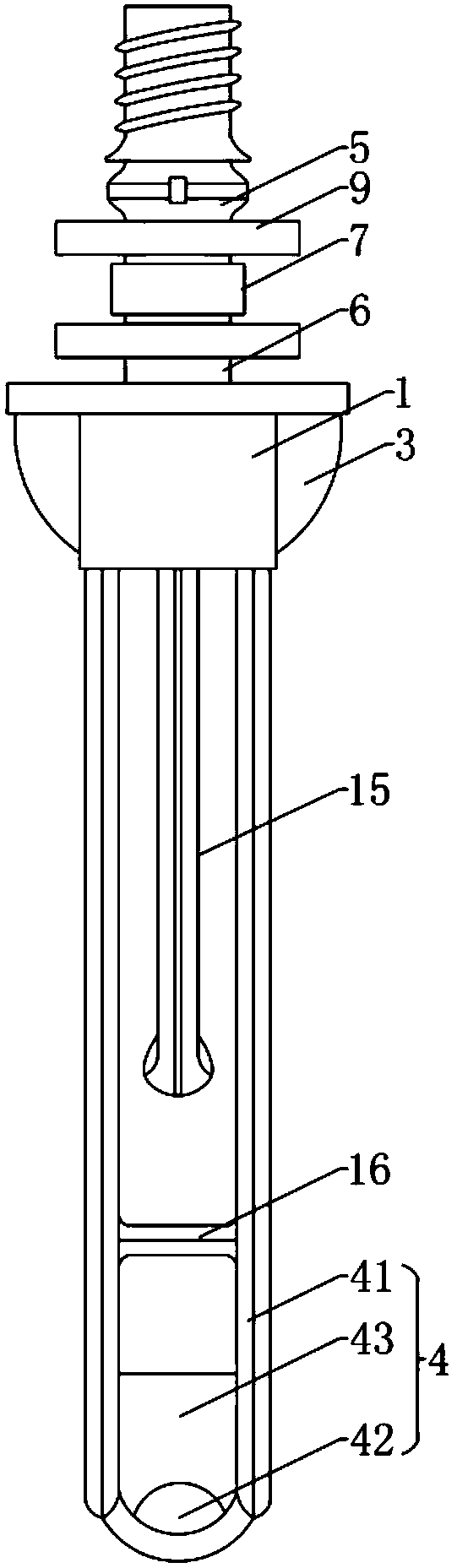

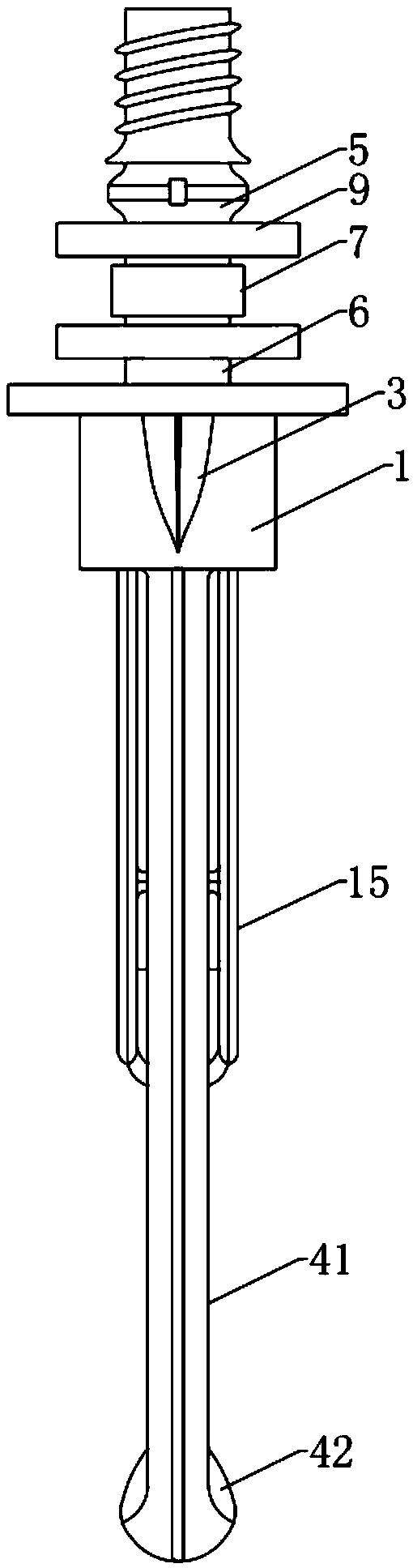

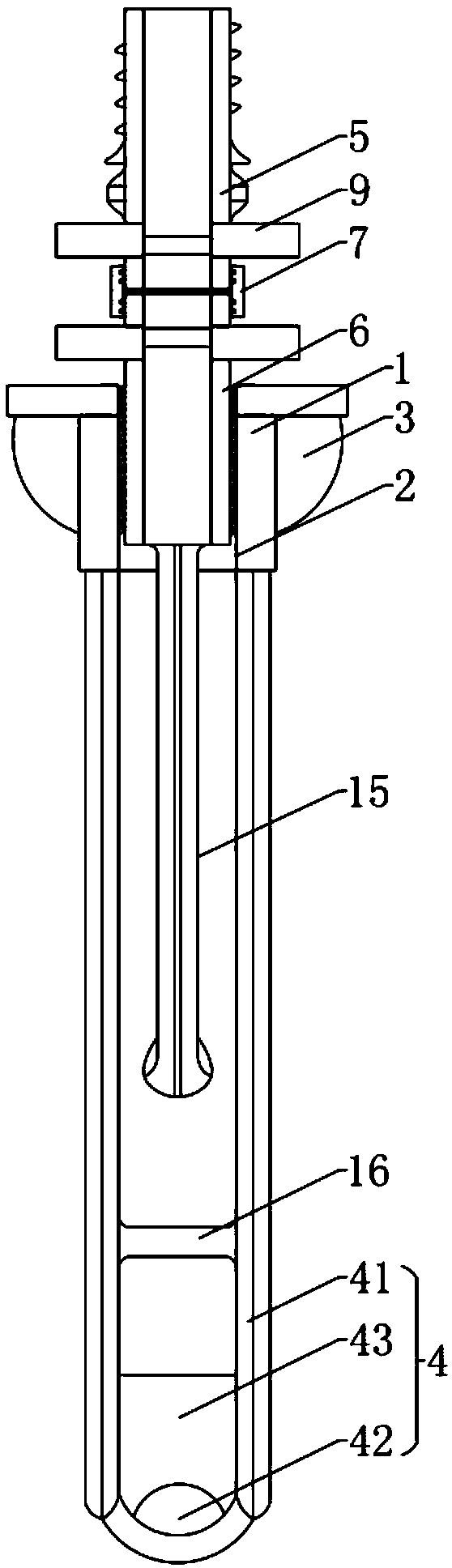

[0058] Such as Figure 1-7 As shown, the mouth tube for semi-solid food nutrition products includes a connection seat 1, a liquid passage 2 that runs through the middle of the connection seat 1, and an mouth pipe part; the liquid passage 2 is provided with an internal thread, and the mouth pipe The parts and the liquid channel 2 are connected by threads, and the two sides of the connecting seat 1 are symmetrically provided with fan-shaped fins 3, and the thickness of the fan-shaped fins 3 gradually decreases along the direction away from the connecting seat 1, and the connecting seat 1 The lower end of the U-shaped guide part 4 is provided with a U-shaped guide part 4, and the U-shaped guide part 4 includes two guide rods 41 vertically arranged, and a tail platform arranged between the bottoms of the two guide rods 41, and the tail part The platform is a streamlined structure with arc-shaped protrusions 42 at the bottom and diversion recesses 43 extending upward along the axia...

Embodiment 2

[0062] Such as Figure 8 , 9 As shown, Embodiment 2 of the present invention is further improved on the basis of Embodiment 1, so as to fully exert the technical advantages of the present invention, which will be illustrated below. For example, the blocking part is at least one blocking rib 10 arranged radially along the blocking ring, and the blocking rings 8 respectively located in the upper opening tube 5 and the lower opening tube 6 are arranged alternately.

[0063] The food or nutritional products passing through the mouth tube parts are sucked out through the barrier ring 8 in the lower tube 6 and the barrier ring 8 in the upper tube 5 in sequence, when the barrier part is at least one barrier rib 10 arranged radially along the barrier ring , and when the positions of the barrier rings 8 in the upper mouth tube 5 and the lower mouth tube 6 are arranged alternately, the diameter of the semi-solid food or nutritional product passing through the barrier ring 8 is cut by t...

Embodiment 3

[0065] Such as Figure 10 , 11 As shown, Embodiment 3 of the present invention is further improved on the basis of Embodiment 1, so as to fully exert the technical advantages of the present invention, which will be illustrated below. For example, the barrier part is at least one fan-shaped barrier piece 11, the center of the fan-shaped barrier piece 11 coincides with the center of the barrier ring 8, and the arc-shaped position of the fan-shaped barrier piece 11 is in contact with the inner wall of the barrier ring 8. Fixed connection, the barrier rings 8 respectively located in the upper opening pipe 5 and the lower opening pipe 6 are arranged in a staggered position.

[0066] The food or nutritional products passing through the mouth tube parts are sucked out through the barrier ring 8 in the lower tube 6 and the barrier ring 8 in the upper tube 5 in sequence. When the barrier part is at least one fan-shaped barrier piece 11, the fan-shaped barrier piece The center of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com