Preparation method of copper vanadate, the copper vanadate prepared through the method, and application of the copper vanadate in lithium ion batteries

A lithium ion battery, copper vanadate technology, applied in copper vanadate, application in lithium ion battery, copper vanadate preparation field, can solve problems such as being unfavorable to improve the energy density of lithium ion battery, etc., to facilitate large-scale production , rich in resources and low cost of preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

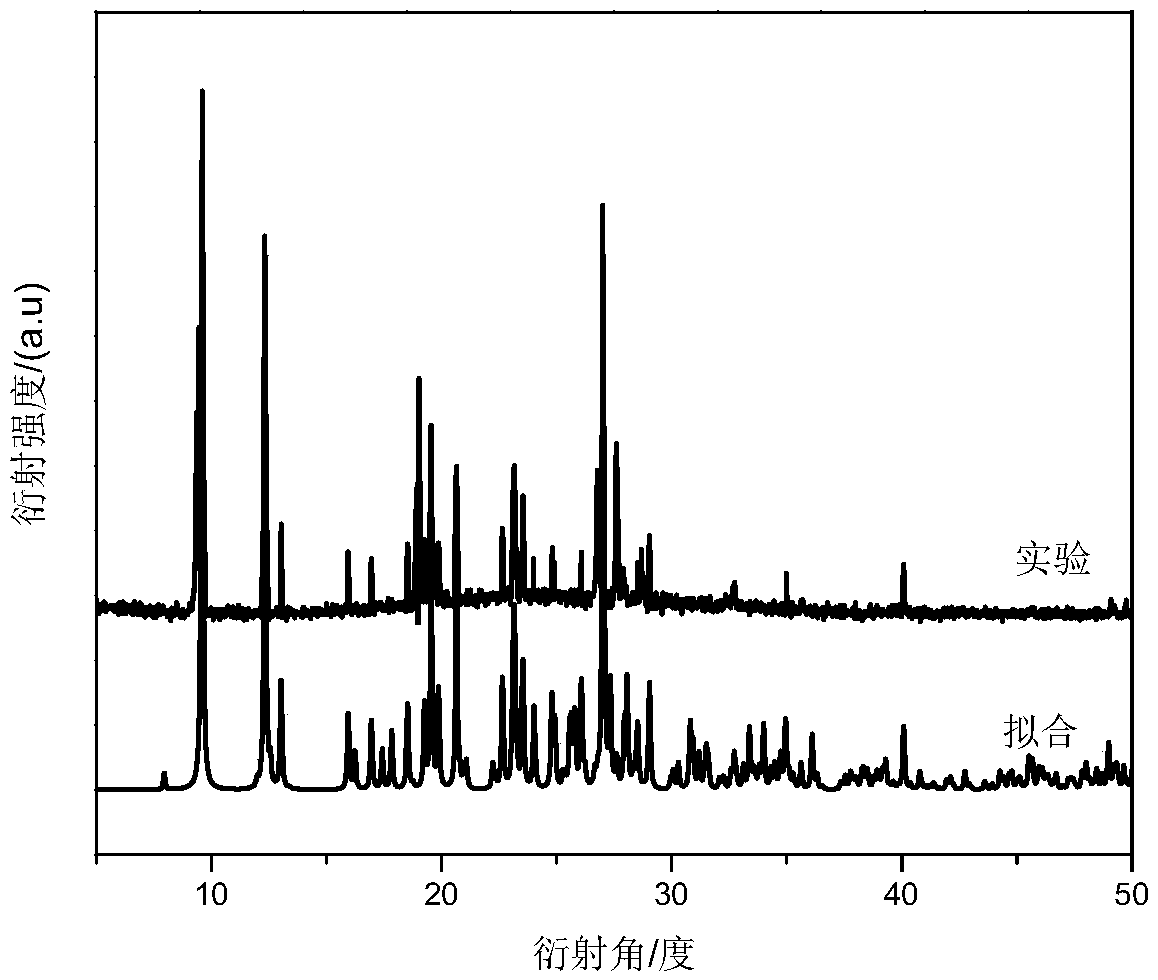

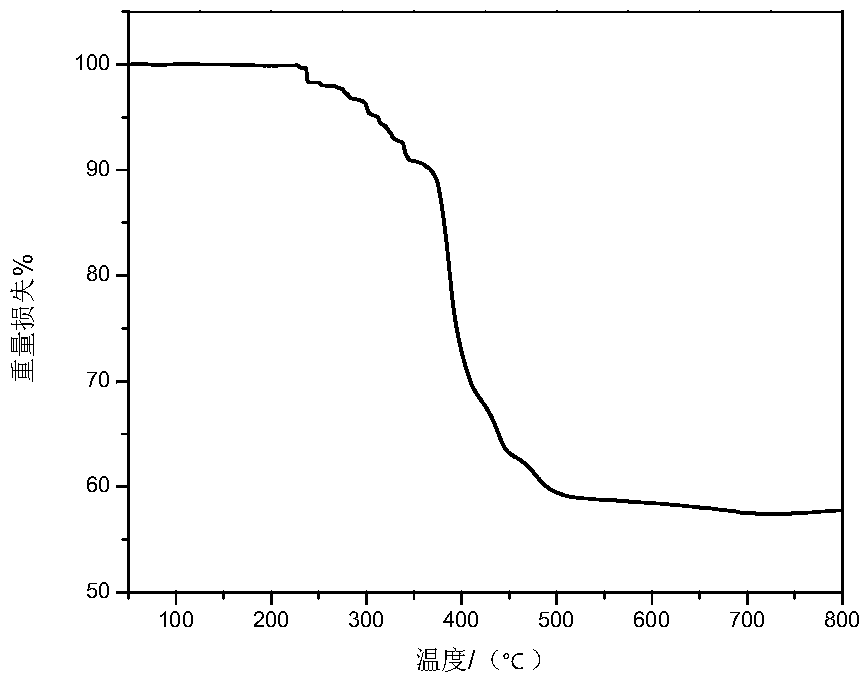

Image

Examples

preparation example Construction

[0033] The embodiment of the present invention relates to a preparation method of copper vanadate, the method comprising the following steps:

[0034] (1) ammonium metavanadate, CuCl 2 2H 2 After O is mixed with o-phenanthroline, it is hydrothermally reacted at 180-200° C. for 30-50 hours to obtain a vanadium-copper precursor.

[0035] In one embodiment of the present invention, ammonium metavanadate, CuCl 2 2H 2 The molar ratio of O to phenanthroline is (1.5-3):1:1. O-phenanthroline, also known as 1,10-phenanthroline, is mainly used as an organic ligand to participate in the preparation of vanadium-copper precursors.

[0036] Further, tetrabutylammonium hydroxide (TBAOH) is also added before the hydrothermal reaction, which is added in a small amount, tetrabutylammonium hydroxide and CuCl 2 2H 2 The molar ratio of O can be (1×10 -4 ~3×10 -4 ):1. TBAOH is mainly used as a template to participate in the preparation of vanadium-copper precursors.

[0037] (2) Calcining...

Embodiment 1

[0041] (1) ammonium metavanadate and copper chloride (CuCl) with a purity of more than 99.9% 2 2H 2 O), o-phenanthroline take by weighing 0.52mmol, 0.28mmol, 0.28mmol respectively.

[0042] (2) Put 0.28mmol of copper chloride in a beaker, add 12ml of deionized water and stir for 10 minutes to form a uniform solution. Then add 0.28mmol o-phenanthroline and 0.52mmol ammonium metavanadate to the solution, and stir for 30m / / .

[0043] (3) adding 0.2ml mass concentration to the solution obtained in step (2) is 10% tetrabutylammonium hydroxide aqueous solution (TBAOH is 7.7 × 10 -5 mmol), after stirring evenly, the homogeneous solution was transferred to a 15ml polytetrafluoroethylene hydrothermal reaction kettle, and reacted at 200°C for 48h. After natural cooling, the reaction solution is filtered, washed, dried, and collected to obtain a vanadium-copper precursor.

[0044] (4) Move the vanadium-copper precursor obtained in step (3) into a crucible, place it in a muffle furnac...

Embodiment 2

[0056] In the preparation process of copper vanadate, TBAOH was not added, and the remaining reagent consumption and operation steps were the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com