Building 3D printing type rapid prototyping composite material

A composite material and 3D printing technology, which is applied in the field of building materials, can solve the problems that the control range of the initial setting time is large, and it is difficult for ordinary technicians to master it. strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

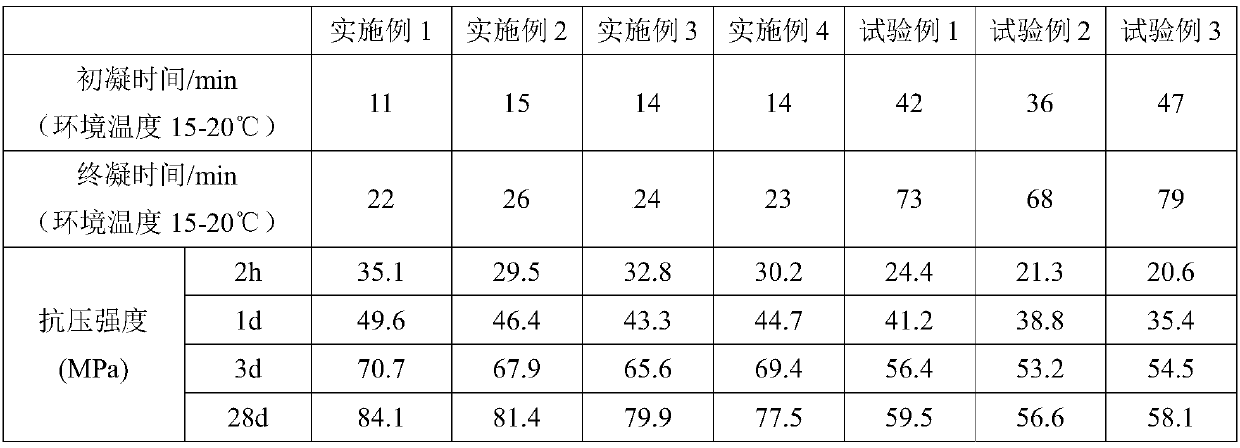

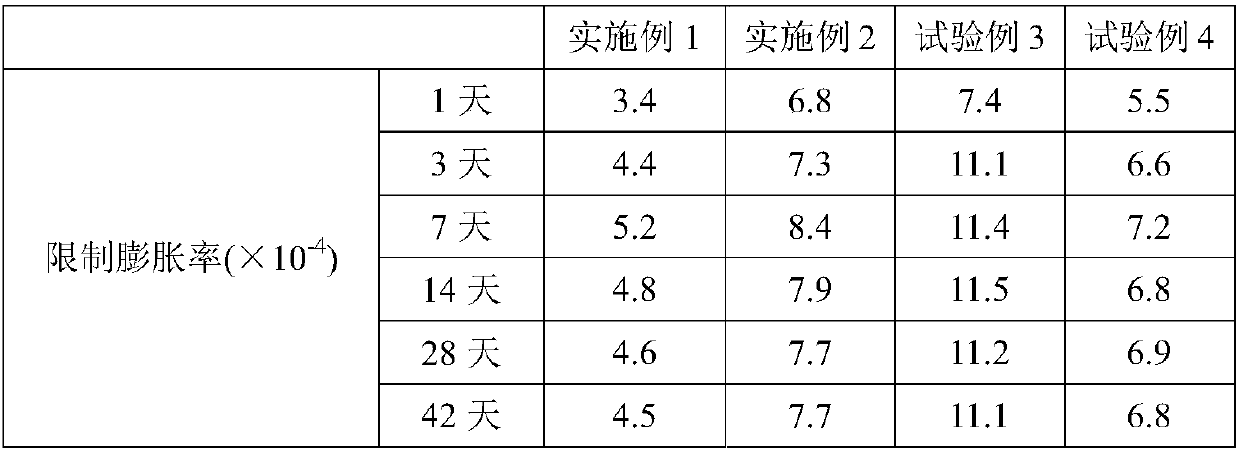

Examples

Embodiment 1

[0028] 1. A building 3D printing rapid prototyping composite material, in parts by weight, said composite material comprising the following raw materials:

[0029] 400 parts of 42.5R rapid hardening sulfoaluminate cement;

[0030] 80 parts of slag fine powder, the fineness is 450m 2 / kg;

[0031] 200 parts of coarse aggregate (stones with particle size less than 5mm);

[0032] 300 parts of fine aggregate (medium sand with a particle size of 0.25-0.5mm);

[0033] 0.8 parts of polycarboxylate PC water reducer;

[0034] Composite coagulation agent, it is made up of 0.6 part of lithium carbonate and 0.8 part of sodium tetraborate;

[0035] A volume stabilizer consisting of 30 parts high calcium fly ash and 28 parts CSA expander.

[0036] 2. The method for simulating and preparing a 3D printed building using the building 3D printing rapid prototyping composite material of this embodiment includes the following steps:

[0037] (1) Put cement, slag micropowder, aggregate and hi...

Embodiment 2

[0041] 1. A building 3D printing rapid prototyping composite material, in parts by weight, said composite material comprising the following raw materials:

[0042]450 parts of 42.5R rapid hardening sulfoaluminate cement;

[0043] 100 parts of slag fine powder, the fineness is 500m 2 / kg;

[0044] 220 parts of coarse aggregate (stones with particle size less than 5mm);

[0045] 240 parts of fine aggregate (medium sand with a particle size of 0.25-0.5mm);

[0046] 0.4 parts of polycarboxylate PC water reducer;

[0047] Composite coagulant, which is made up of 0.8 part of lithium carbonate and 1.0 part of sodium tetraborate;

[0048] A volume stabilizer consisting of 33 parts high calcium fly ash and 25 parts CSA expander.

[0049] 2. The method for simulating and preparing a 3D printed building using the building 3D printing rapid prototyping composite material of this embodiment includes the following steps:

[0050] (1) Put cement, slag micropowder, aggregate and high-ca...

Embodiment 3

[0054] 1. A building 3D printing rapid prototyping composite material, in parts by weight, said composite material comprising the following raw materials:

[0055] 300 parts of 42.5R rapid hardening sulfoaluminate cement;

[0056] 125 parts of slag fine powder, the fineness is 500m 2 / kg;

[0057] 250 parts of coarse aggregate (stones with particle size less than 5mm);

[0058] 290 parts of fine aggregate (medium sand with a particle size of 0.25-0.5mm);

[0059] 0.2 parts of polycarboxylate PC water reducer;

[0060] Composite coagulant, which is made up of 0.4 part of lithium carbonate and 0.6 part of sodium tetraborate;

[0061] A volume stabilizer consisting of 25 parts high calcium fly ash and 20 parts CSA expander.

[0062] 2. The method for simulating and preparing a 3D printed building using the building 3D printing rapid prototyping composite material of this embodiment includes the following steps:

[0063] (1) Put cement, slag micropowder, aggregate and high-c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com