Preparation method of Guang paint

A technology of wide lacquer and raw lacquer, which is applied in the field of preparation of wide lacquer, can solve the problems of low adhesion, poor film-forming effect, easy to fall off, etc., and achieve the effect of excellent film-forming property and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Embodiment 1, a kind of preparation method of wide paint, comprises the steps:

[0021] Step S1, performing impurity-removing and filtering treatment on the raw lacquer;

[0022] Step S2, put the raw lacquer into the lacquer cooking container and boil to remove water to obtain purified raw lacquer; Step S3, put tung oil into a clean pot, then place it on a heater to heat, stir and test, stop heating and let stand after the test is passed Get cooked tung oil;

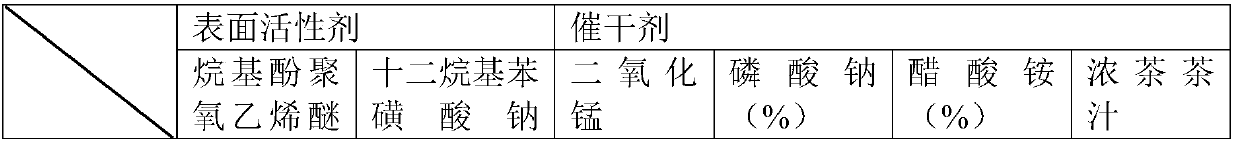

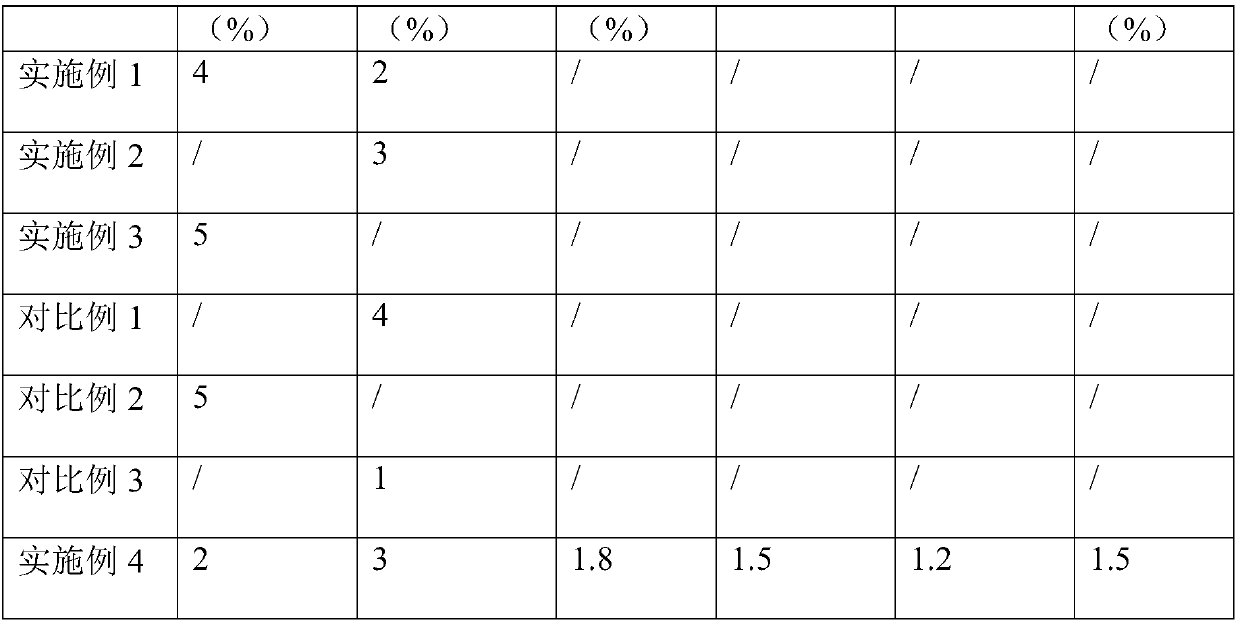

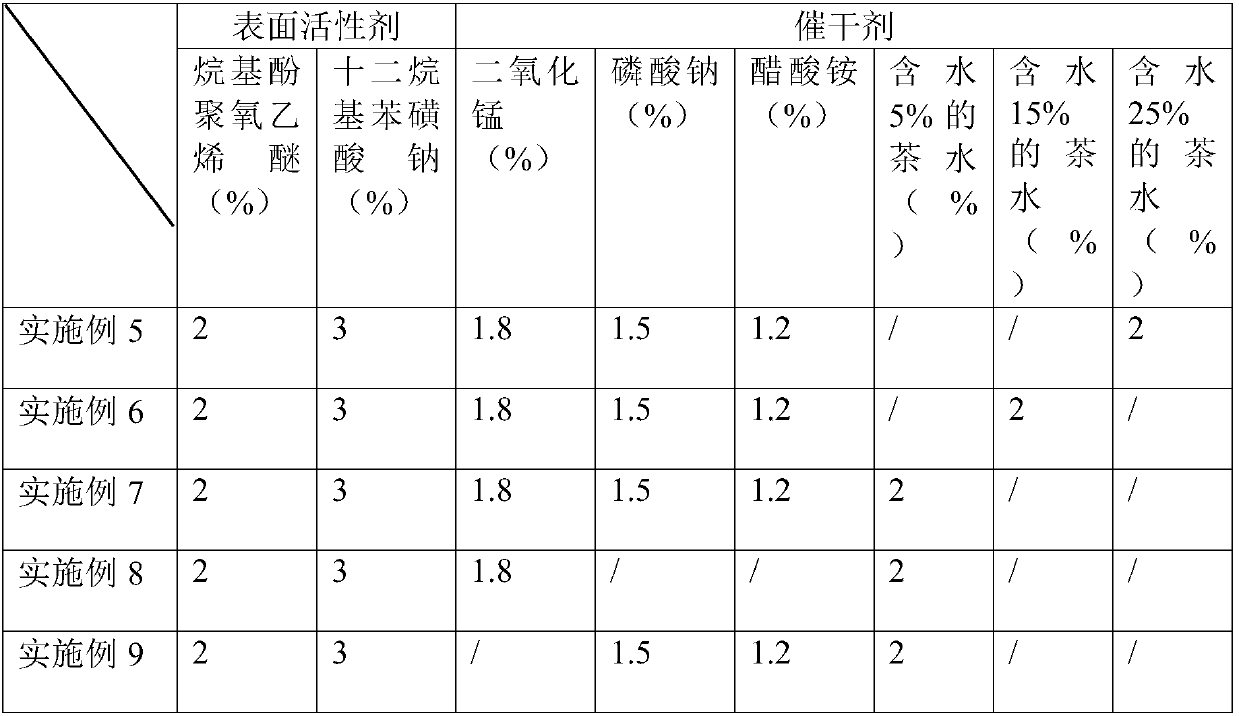

[0023] Step S4, mixing the purified raw lacquer obtained in the step S2 with the cooked tung oil obtained in the step S4 in proportion to obtain a pre-product, and then adding a surfactant to the pre-product to obtain a finished product.

Embodiment 2

[0024] Example 2, a preparation method of lacquer, differs from Example 1 in that the raw lacquer is subjected to anhydrous sodium sulfate water removal treatment prior to step S1; and after the impurity removal treatment by filtering in step S1, Put the raw lacquer into the lacquer boiling container and boil to remove the moisture for 30 minutes.

[0025] Step S1 and step S2 are specifically as follows:

[0026] Step S1, first adding anhydrous sodium sulfate to the raw lacquer for water removal treatment, and then performing impurity removal and filtration treatment for the raw lacquer;

[0027] Step S2, putting the raw lacquer into the lacquer boiling container and boiling to remove water for 35 minutes to obtain purified raw lacquer.

Embodiment 3

[0028] Embodiment 3, a kind of preparation method of wide lacquer, differs from embodiment 2 in that step S3, put tung oil into a clean pot, then place it on a heater to heat, stir and detect, and the detection operation is to use Test the cooked tung oil in a clean pot by thermometer measurement. When the temperature reaches 180°C, control the heating rate of the heater to 5°C / min, remove the heater after heating for 15 minutes, stop heating and let stand to obtain cooked tung oil.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com