Production technology for producing high-strength corrugated paper by using wastepaper

A production process and corrugated paper technology, applied in the processing of waste paper, pulp by-product recycling, paper, etc., can solve the problems of fiber physical performance reduction, reduce investment and additives, and improve the quality of paper

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

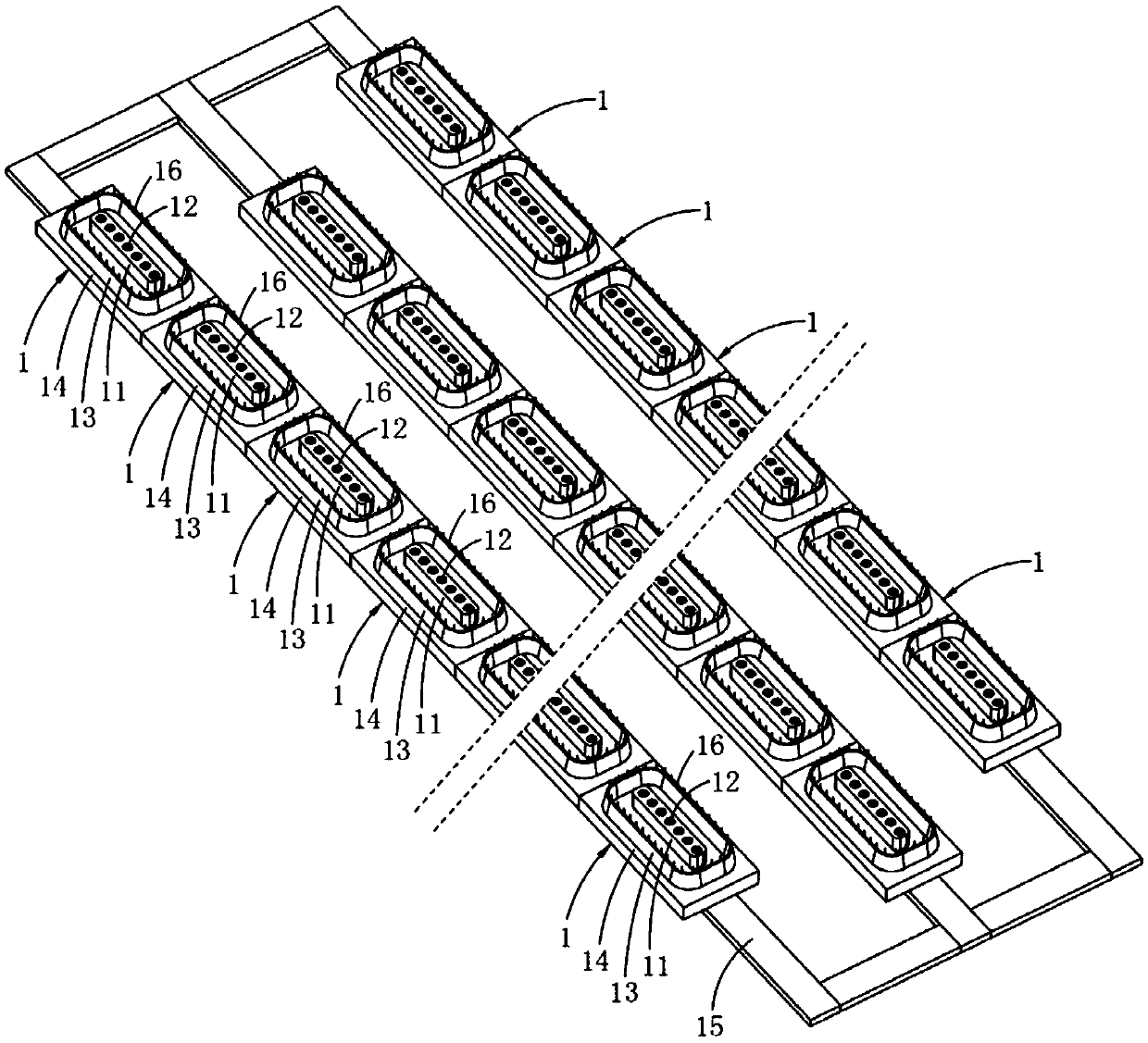

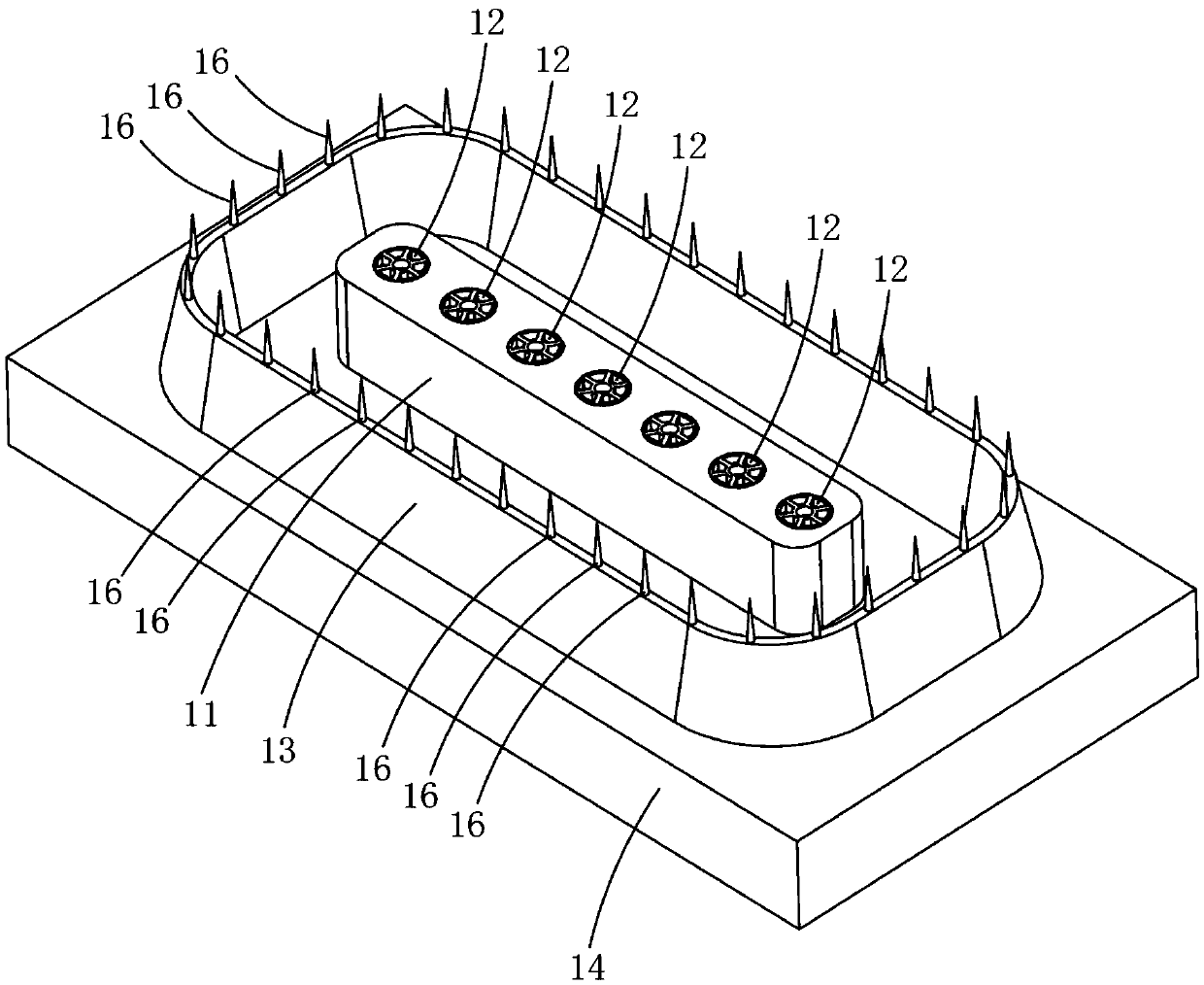

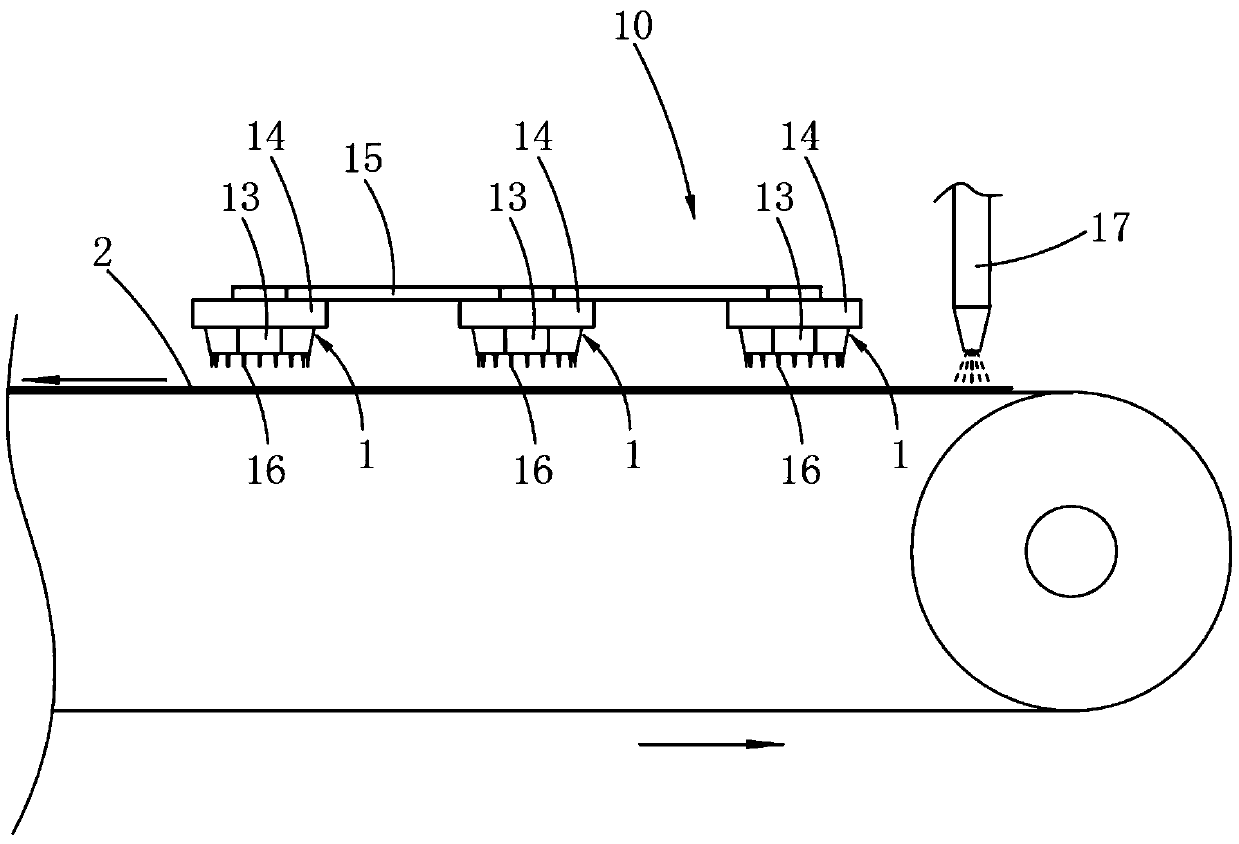

Method used

Image

Examples

Embodiment Construction

[0058] The following are only preferred embodiments of the present invention, and therefore do not limit the protection scope of the present invention.

[0059] A production process for producing high-strength corrugated paper using waste paper, comprising the following steps,

[0060] In the pulping step, the recovered waste paper is put into the pulping bucket. The pulping bucket is preferably a double-D pulping bucket. The double-D pulping bucket has two plane-shaped sides to improve paper shredding efficiency and reduce fiber loss. Damage rate, inject the recycling water of the papermaking enterprise into the pulping bucket, and shred the strip-shaped waste paper into a slurry, and divide the slurry in the pulping bucket to obtain the waste paper slurry;

[0061] In the sludge sewage treatment step, the heavy slag is removed from the bottom of the crushing tank, the sewage and sludge in the heavy slag are separated through the mud-water separation equipment, the sludge is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com