Single-side bolt connecting beam column anti-progressive-collapse reinforcing joint and construction method thereof

A technology of unilateral bolts and joints, which is applied in the direction of building components, earthquake resistance, building types, etc., can solve the problems of loss of bearing capacity of key load-bearing columns or key joints, very high processing and construction precision requirements, buckling of steel pipe column walls, etc. It achieves the effect that the stress concentration phenomenon is not obvious, it is convenient for factory prefabrication, and the bearing capacity is improved

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

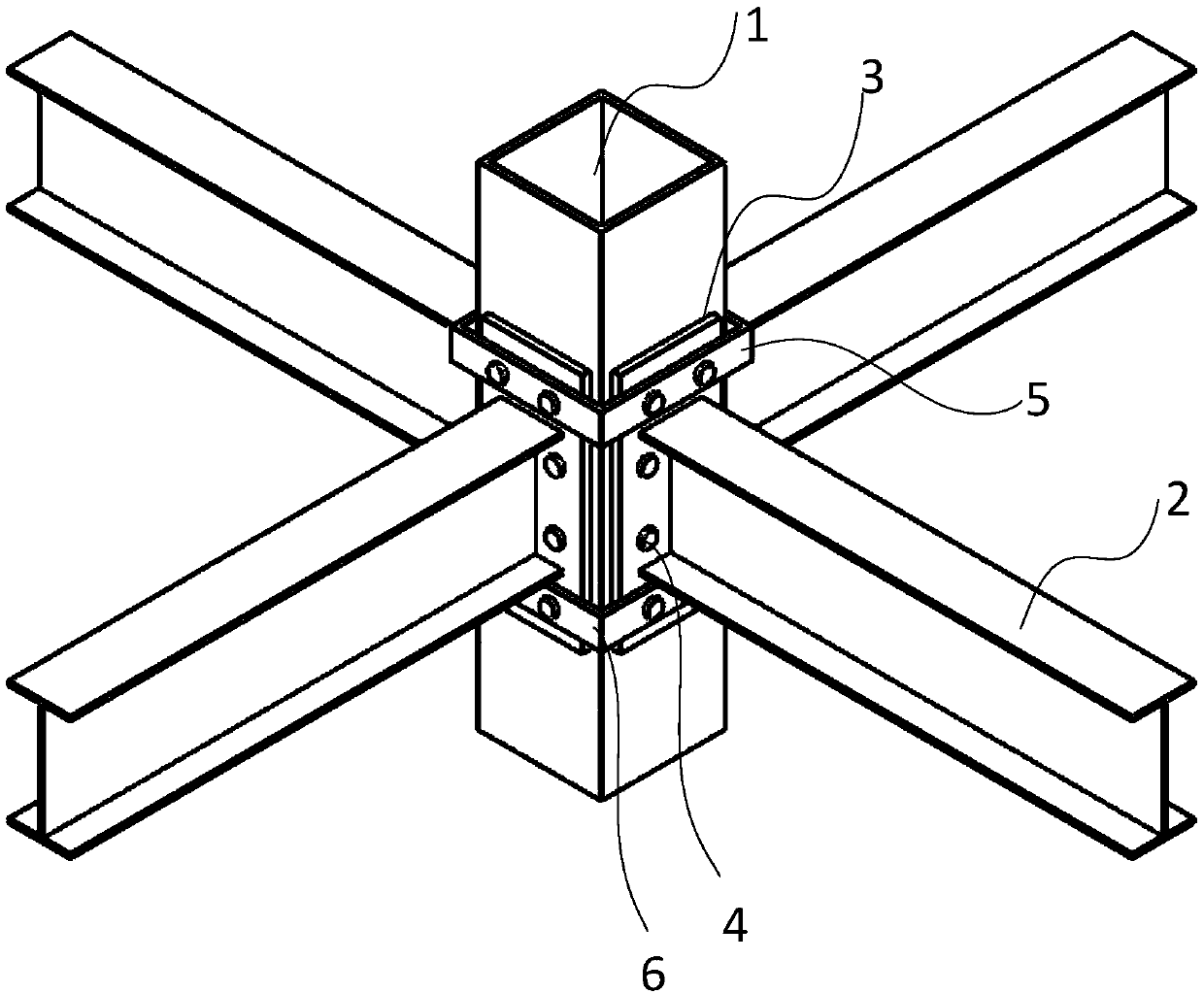

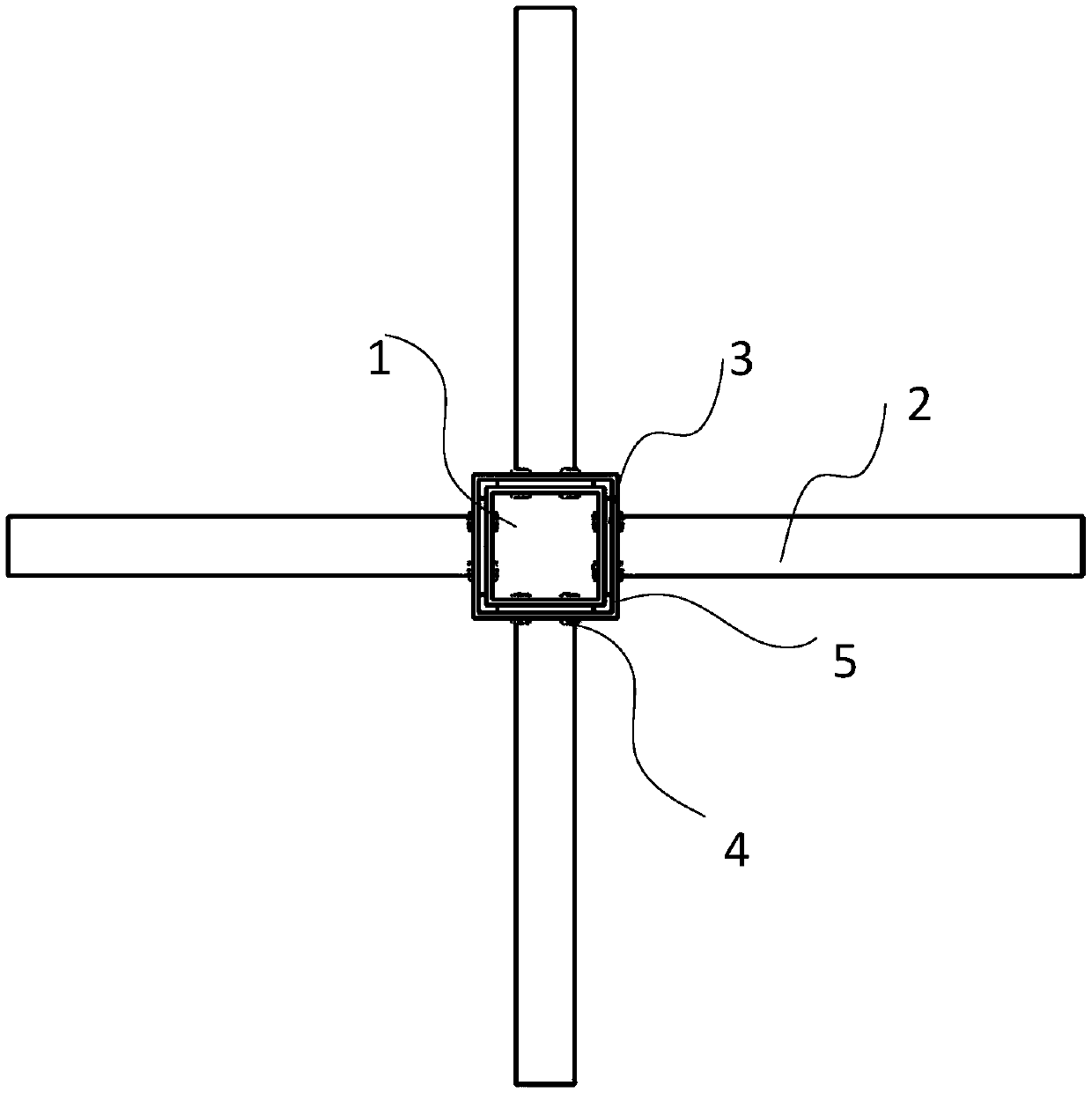

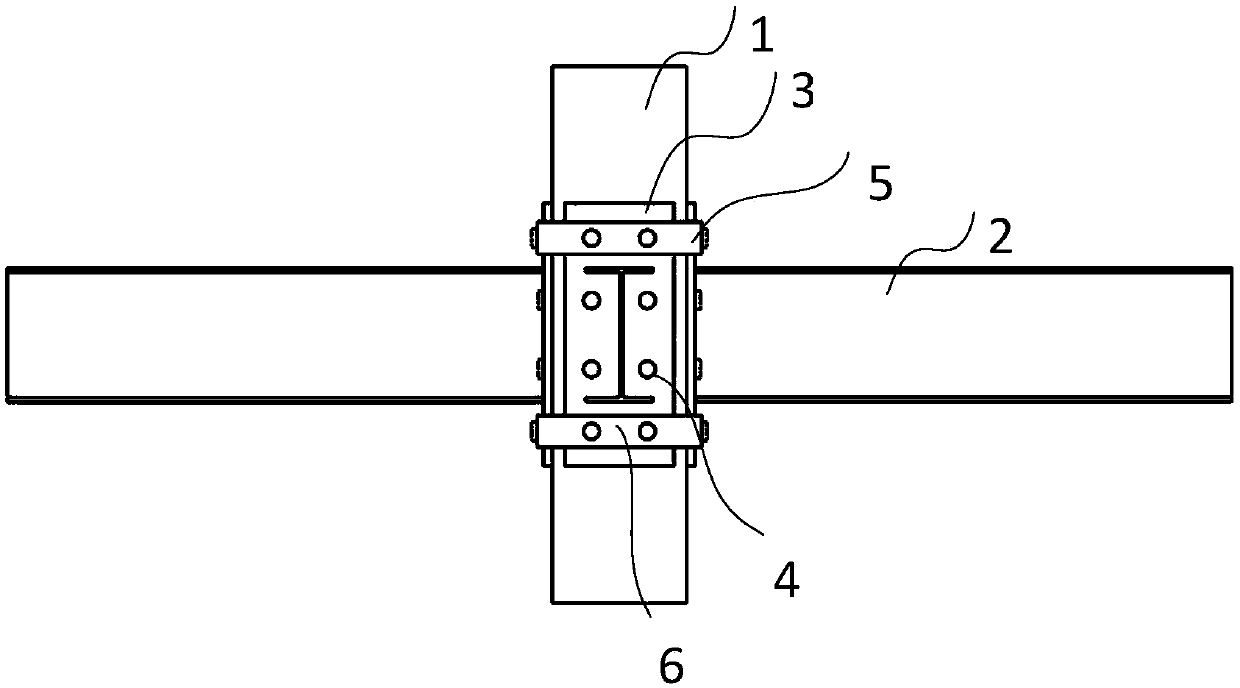

[0032] Such as Figure 1 to Figure 7 As shown, a unilateral bolt-connected beam-column anti-continuous collapse reinforcement node includes a rectangular steel pipe column 1, an H-shaped steel beam 2, an end plate 3 extending from the end of the beam, a one-way locking high-strength bolt 4, an upper rectangular hoop and a lower rectangular ferrule.

[0033] The rectangular steel pipe column 1 is made of a welded box-shaped composite cross-section column, which is pre-welded in a factory.

[0034] The overhanging end plate 3 at the beam end is fixedly connected to the end of the H-shaped steel beam 2. At the same time, the overhanging end plate 3 at the beam end is attached to the wall plate of the rectangular steel pipe column 1 and passed t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com