High-temperature hot air device suitable for waste gas circulation heating of brick kiln

A waste gas circulation and hot air device technology, applied in waste heat treatment, furnace control devices, lighting and heating equipment, etc., can solve the problems of high investment cost, high maintenance cost, complex equipment, etc., achieve good adaptability, reduce energy consumption, The effect of improving the brick production rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

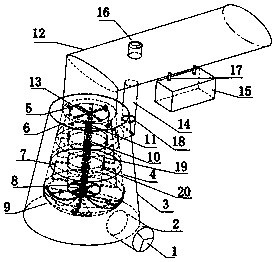

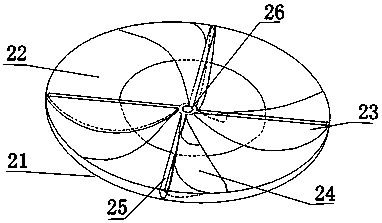

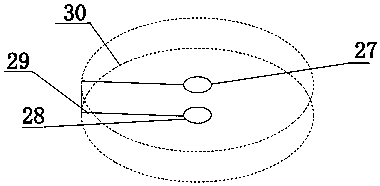

[0029] see Figure 1-9 , in an embodiment of the present invention, a high-temperature hot air device suitable for exhaust gas circulation heating of a brick kiln includes a hot air flow channel, a heater and an intelligent control system. The hot air flow channel includes a blower 1, an air inlet pipe 2, an outer cylinder 3 and The inner cylinder body 4 and the rotating body 19, the outer cylinder body 3 and the inner cylinder body 4 are all in the shape of a circular platform, the side wall of the outer cylinder body 3 is equipped with an air inlet pipe 2, and the other end of the air inlet pipe 2 is equipped with a blower 1, and The air duct 2 communicates with the outer cylinder 3, the inner cylinder 4 is installed inside the outer cylinder 3, the inner surface of the inner cylinder 4 is covered with heat insulating material, and an outer laminar flow is formed between the outer cylinder 3 and the inner cylinder 4 The cross-sectional area of the outer flow channel is equ...

Embodiment 2

[0038] On the basis of Embodiment 1, a temperature-regulating pipe 14 is installed on the side wall of the outer cylinder 3, and the other end of the temperature-regulating pipe 14 communicates with the air outlet pipe 12. A temperature-regulating valve 18 is installed inside the temperature-regulating pipe 14. A pressure relief valve 16 is installed on the top of the air duct 12, and the control box 15 controls the blower 1 or the temperature regulating valve 18 to adjust the air temperature according to the measurement data of the temperature sensor 17. When the temperature is high, adjust the opening degree of the temperature regulating valve 18, draw cold air from the outer channel through the temperature regulating pipe 14 and send it to the air outlet pipe 12 to reduce the air temperature. When the pressure in the air outlet pipe 12 is too high, the pressure is released through the pressure relief valve 16 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com