Static friction force testing system for elevator speed limiter

A technology of elevator speed limiter and static friction force, which is applied in the field of elevator speed limiter test equipment, can solve the problems of inconvenient and accurate test device use, lack of test equipment, elevator malfunction, etc., and achieve convenient test results and test reports, Convenient test operation, stable operation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

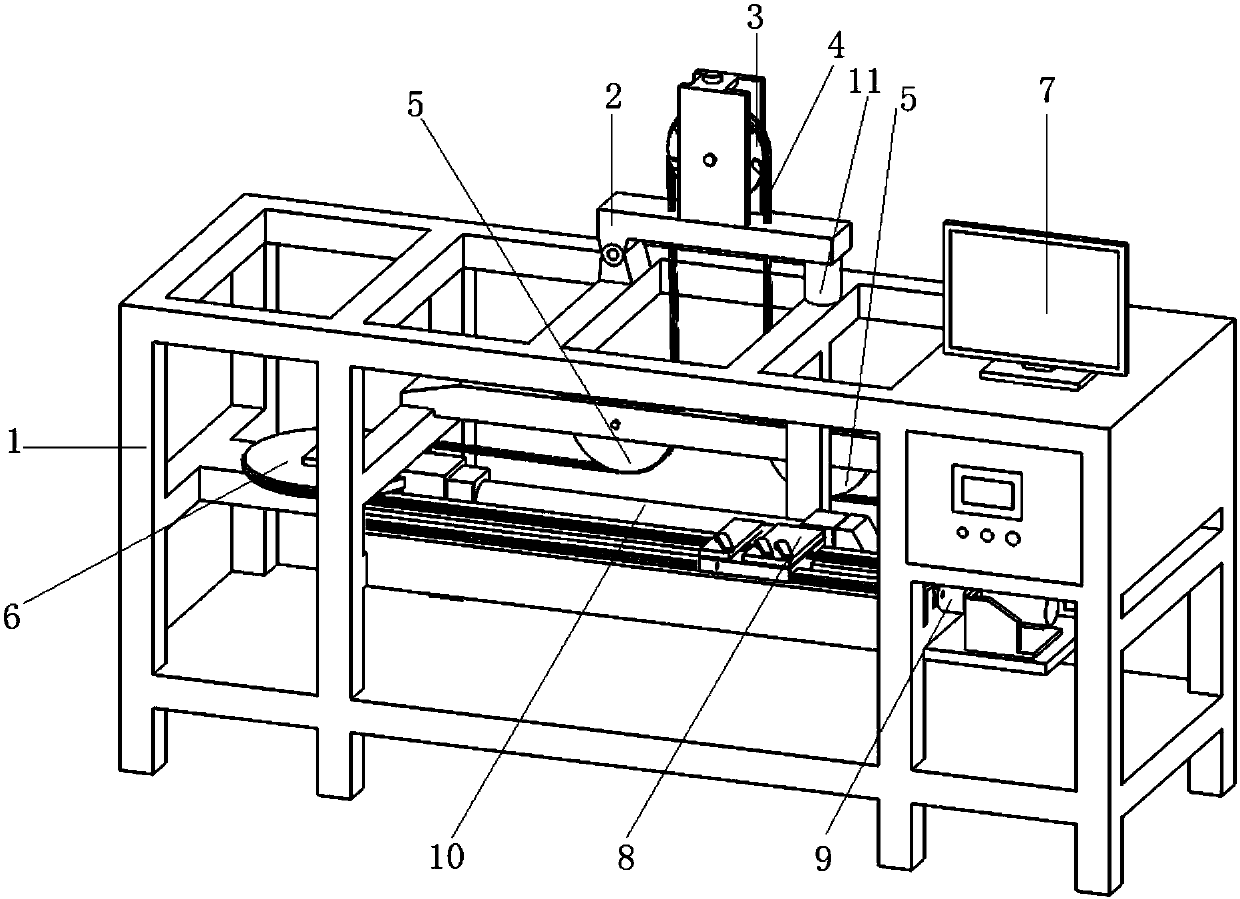

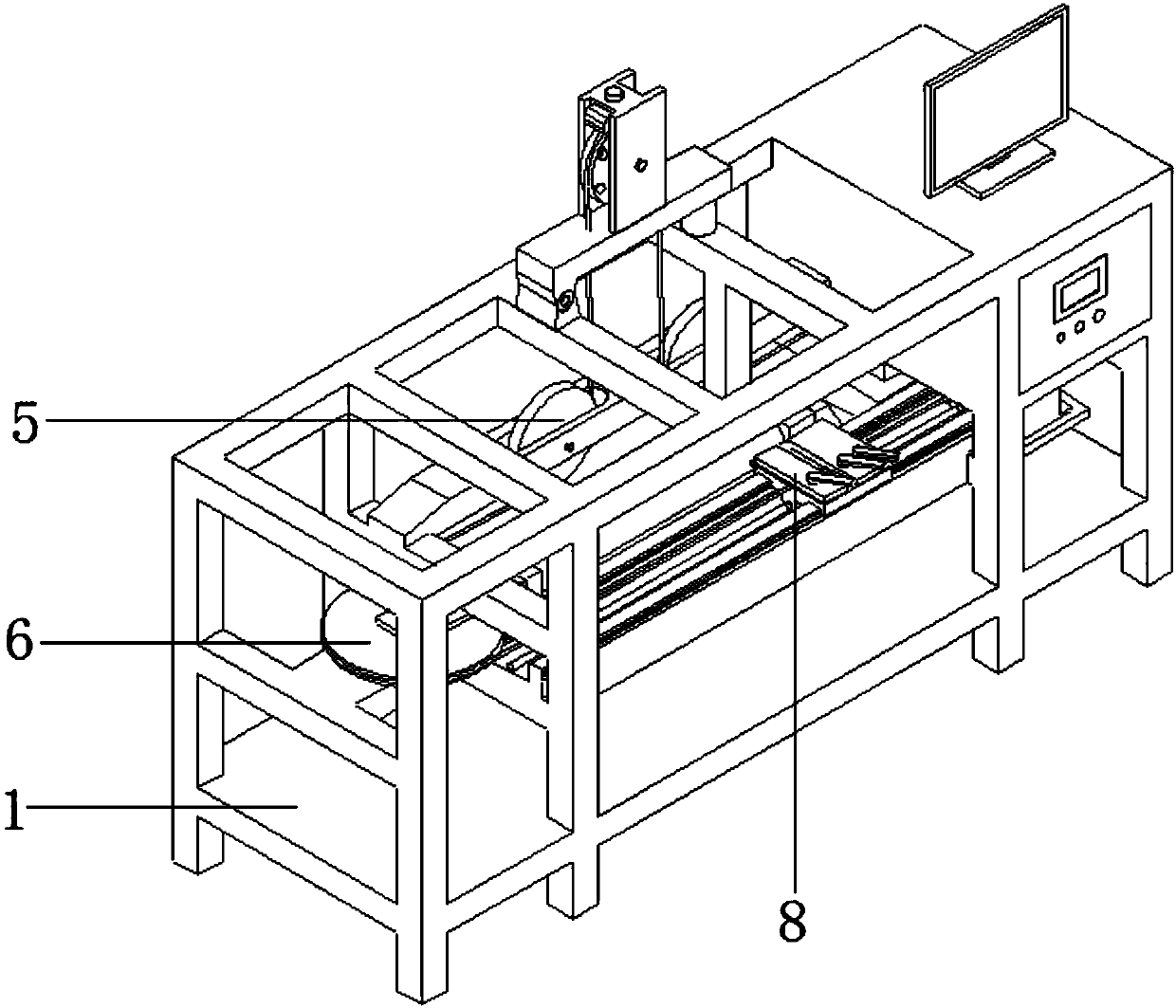

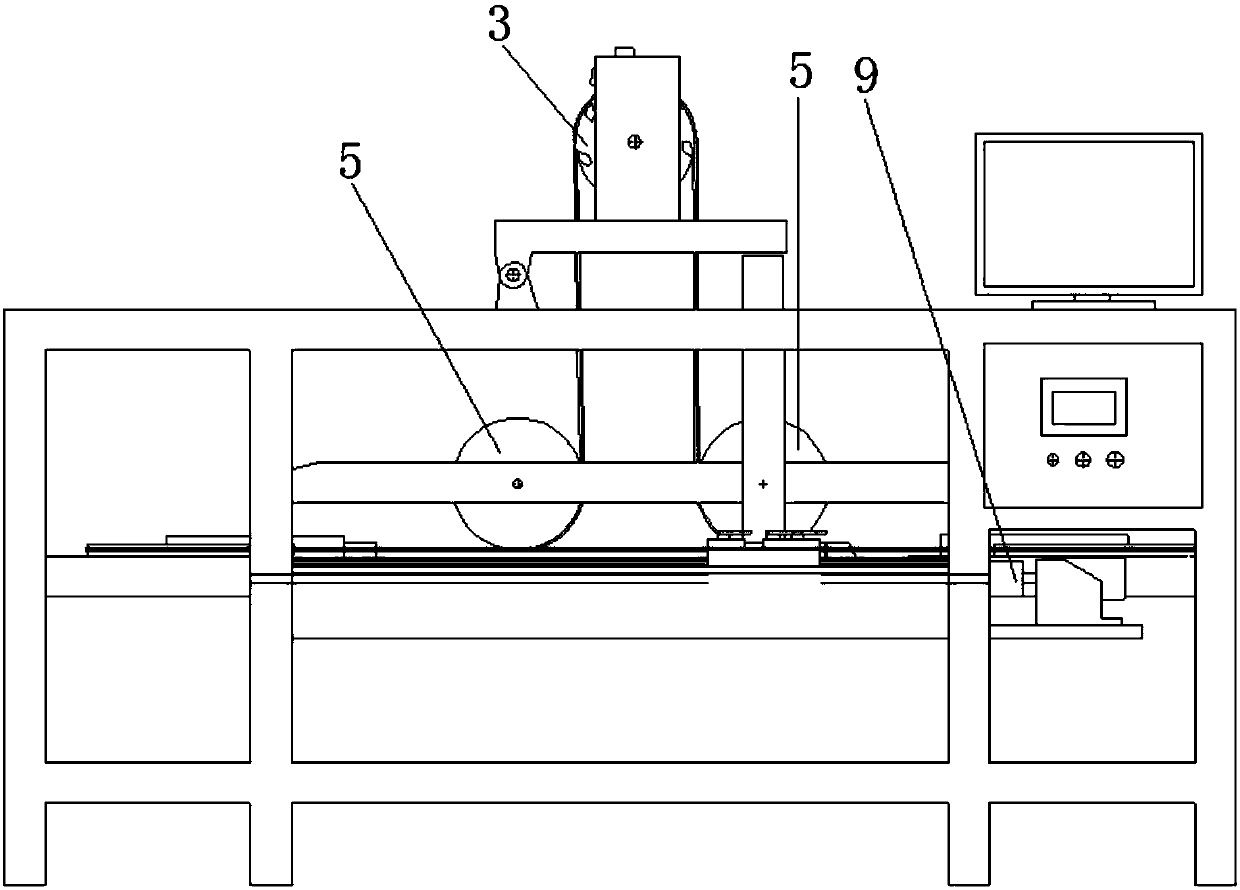

[0024] A static friction test system for elevator speed limiter, such as Figure 1-3 As shown, it includes a support frame 1, a steel wire rope 4, a fixed platform arranged on the upper part of the support frame 1 for installing the speed governor 3, a traction wheel assembly that guides the steel wire 4, and a drive mechanism 9 that drives the steel wire 4 to move. The support frame 1 It is a square frame and welded by steel. The wire rope 4 bypasses the governor sheave, the traction wheel assembly and the driving mechanism 9 in turn. The two ends of the wire rope 4 are fixed by the locking mechanism 8 and form a closed loop. The bottom of the fixed platform 2 and the support There is a pressure sensor 11 between the frame 1, the maximum bearing pressure is 5000N, and the accuracy is 5‰. The pressure sensor 11 is connected to the external data acquisition unit 7. When working, the driving mechanism 9 drives the wire rope 4 to move, and the speed limiter sheave stops. After tha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com