Nonlinear ultrasonic detection system and detection method for reflective metal creep performance

A non-linear ultrasonic and metal creep technology, applied in the analysis of solids using sound waves/ultrasonic waves/infrasonic waves, material analysis using sound waves/ultrasonic waves/infrasonic waves, and measuring devices. Surface cleaning and grinding work and other issues, to achieve the effect of accurate results, fast automatic verification, and saving on-site debugging time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

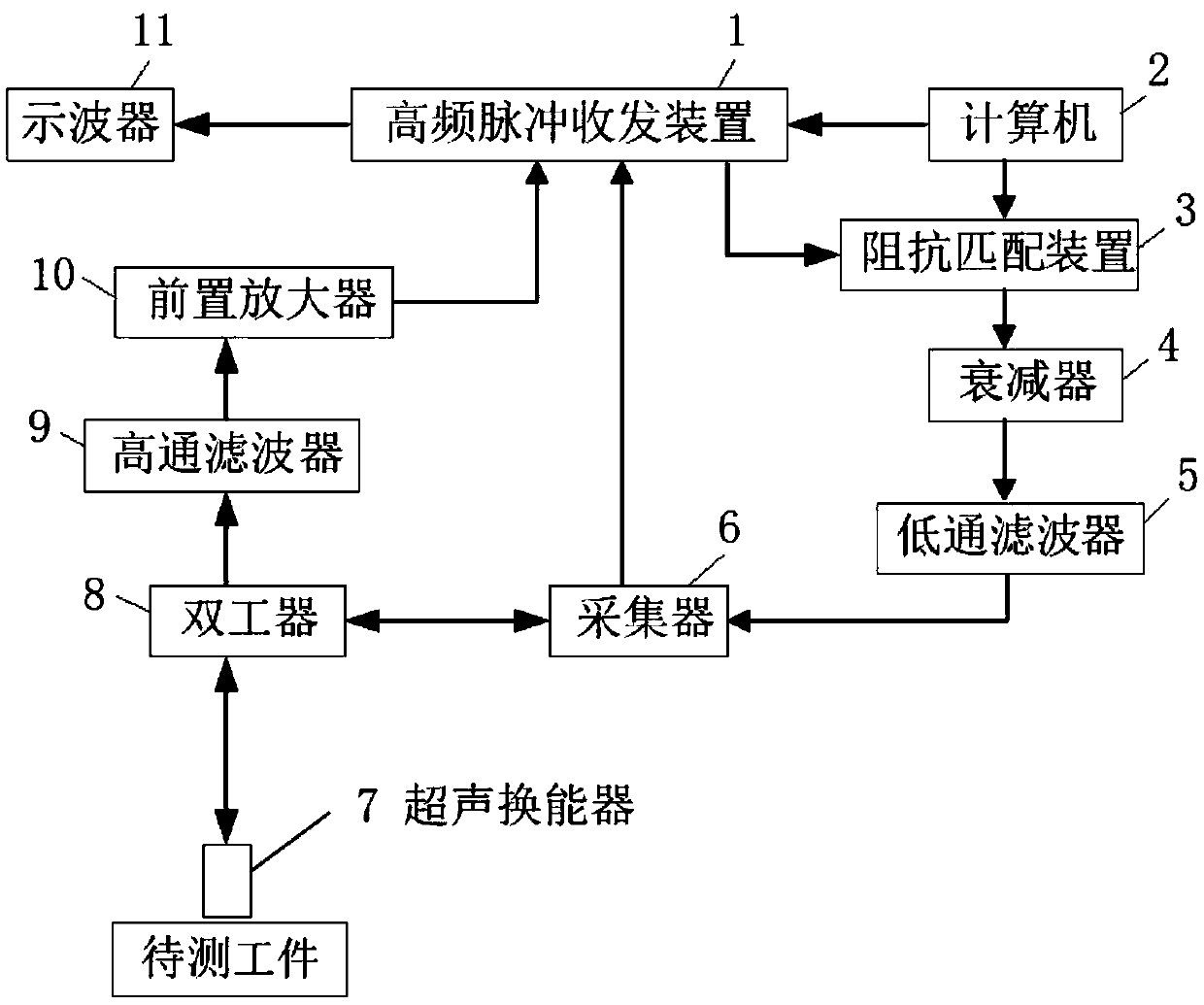

[0049] Non-linear ultrasonic testing system for metal creep performance, including: signal transmission acquisition and display storage module, signal transmission module and signal reception module;

[0050] The described signal emission acquisition and display storage module includes: a high-frequency pulse transceiver device 1, a computer 2, and an oscilloscope 11; wherein, the computer 2 is used to adjust the high-frequency pulse transceiver device 1, and the oscilloscope 11 is used to feed back and display high-frequency The data information stored by the pulse transceiver device 1;

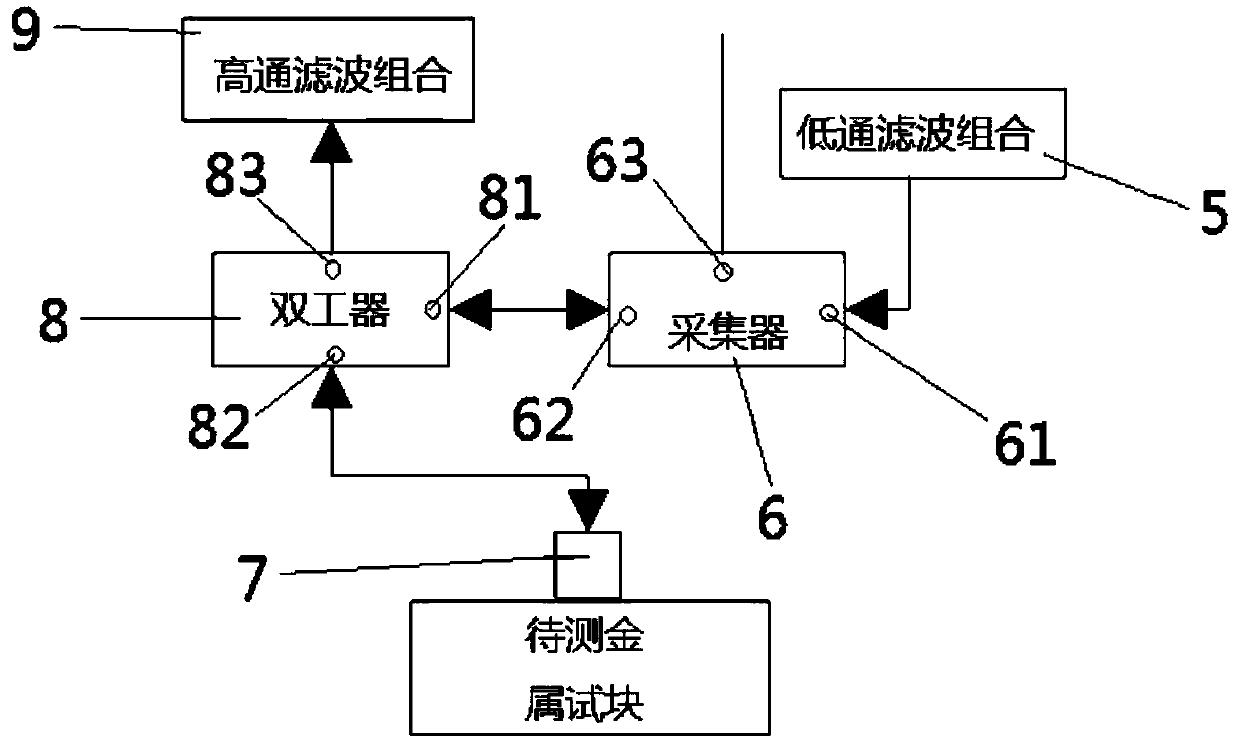

[0051] The signal transmitting module includes: a high-frequency pulse transceiver device 1, an impedance matching device 3, an attenuator 4, a low-pass filter 5, a collector 6, a duplexer 8 and an ultrasonic transducer 7; wherein the The pulse transmitting end of the high-frequency pulse transceiving device 1, the impedance matching device 3, the attenuator 4, and the low-pass filter 5 are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com